Electric heating rotary roller, fully automatic machine for dried fruits and roasted seeds and nuts and control circuit of fully automatic machine for dried fruits and roasted seeds and nuts

An electric heating, fully automatic technology, which is applied in the direction of using electric mode for temperature control, auxiliary controller with auxiliary heating device, food processing, etc. The effect of a wide range, improving work efficiency, and large market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

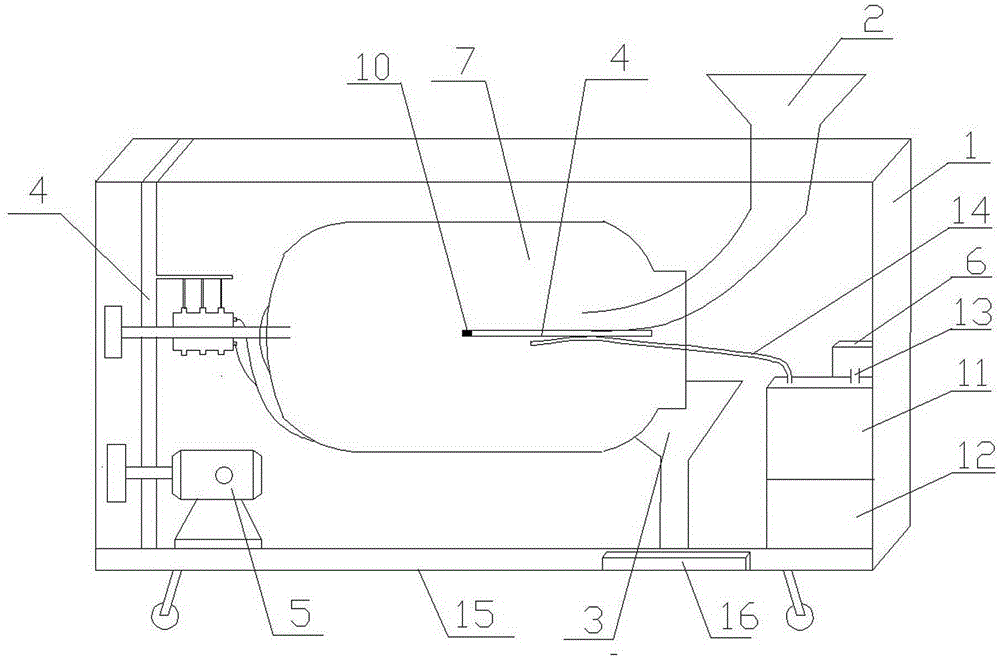

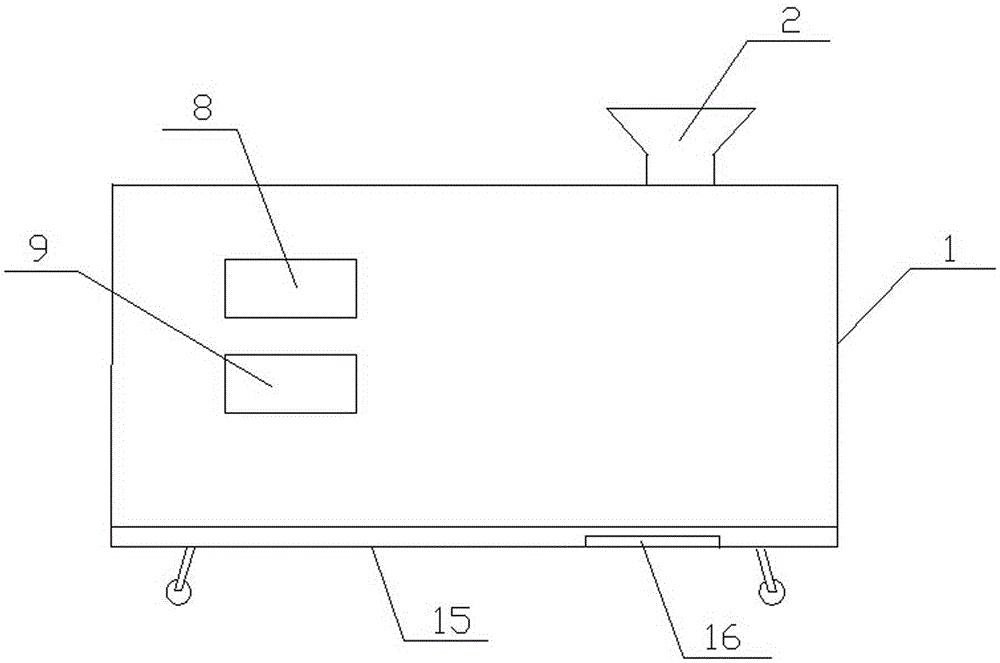

[0024] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

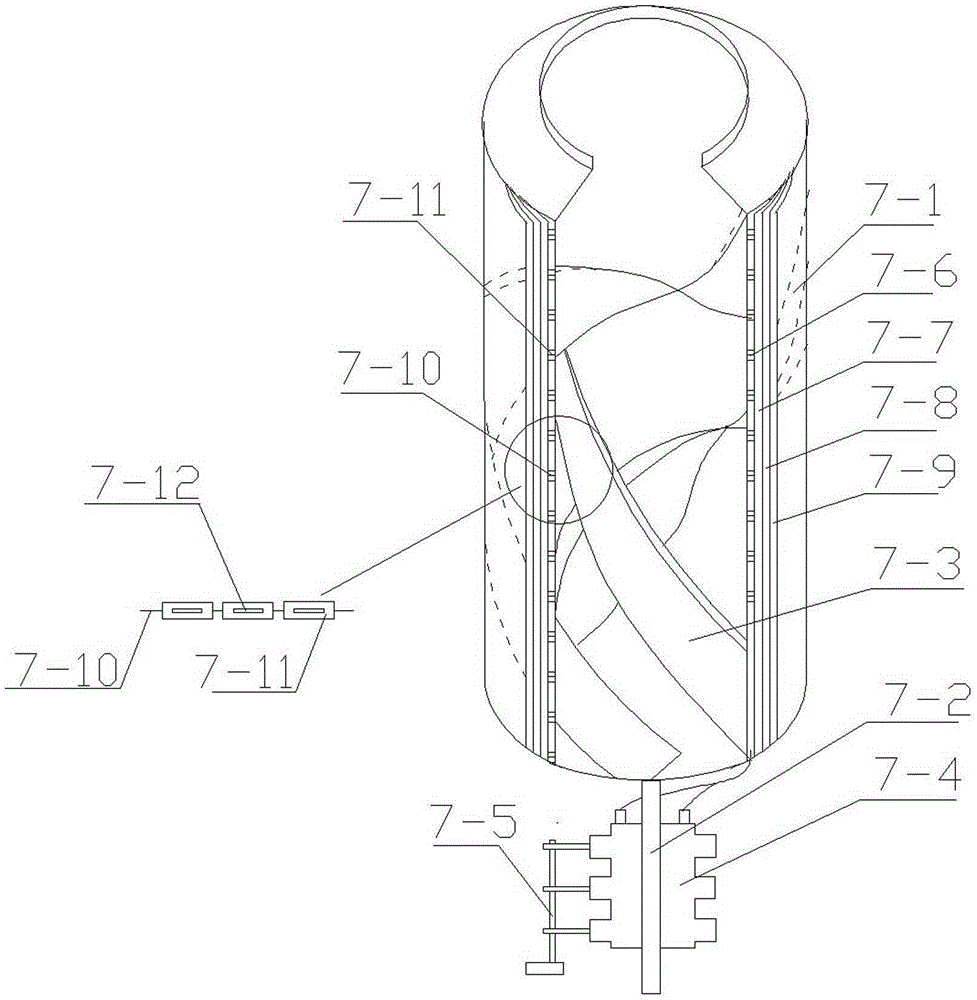

[0025] see figure 1 , an electrically heated rotary drum of the present invention, comprising a drum body 7-1 and a bearing 7-2, one end of the drum body 7-1 is open, the other end is fixedly connected to the bearing 7-2, and the inside of the drum body 7-1 Folded helical blades 7-3 are fixed on the chamber wall, and collector rings 7-4 and carbon brushes 7-5 matching the collector rings are also included. The outside of the cylinder wall of the drum body 7-1 is sequentially A heating layer 7-6, an insulating layer 7-7, an insulating layer 7-8, and an iron sheet 7-9 are fixed, and the heating layer 7-6 is fixed with electric furnace wires 7-10 evenly distributed on the drum body 7-1. Magnetic bead 7-11 is arranged on wire 7-10 overcoat, and electric furnace wire 7-10 is electrically connected with collector ring 7-4 fixed on bearing 7-2, and collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com