Method and device for washing and purifying ocean engineering power tail gas only through seawater

A washing device and marine engineering technology, applied in chemical instruments and methods, separation methods, combustion engines, etc., can solve the rising environmental and economic costs, lose the environmental protection advantages of high-efficiency and emission-reducing seawater washing processes, and fail to become a substitute for low-sulfur fuel oil Practical technology and other issues to achieve remarkable technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

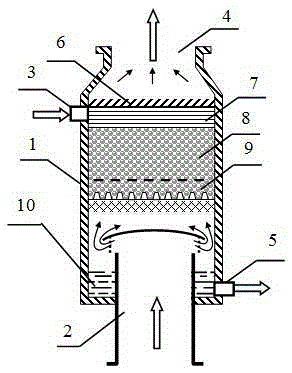

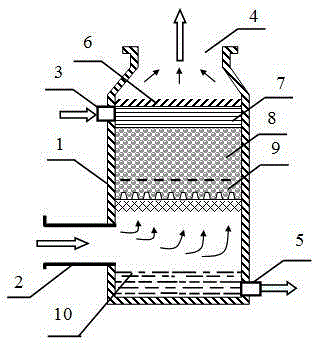

[0043] Embodiment 1: It is the basic embodiment of a kind of marine engineering power tail gas of the present invention only using seawater to wash and purify the method, as attached figure 1 , 2 , 3a, 3b, and 4, the implementation steps include introducing engine exhaust gas and seawater to the washing device, washing the tail gas with seawater in the washing device, and discharging the cleaned tail gas and washing seawater from the washing device; it is characterized in that the Washing the tail gas with seawater in the washing device is the packing washing carried out through the packing layer in the packing washing device. The packing washing device includes a packing layer with a dry packing factor of 10-2000 / m, and the time for the tail gas to pass through the packing layer is 0.05 to 20 seconds. The dry filler factor (Factor) is a / ε 3 , the unit is 1 / m, where a is the total specific surface area of the packing layer, and the unit is m 2 / m 3 , ε is the ratio of t...

Embodiment 2

[0049] Embodiment 2: is a further embodiment on the basis of Embodiment 1.

[0050] The packing washing through the packing layer refers to the washing by directly introducing the engine exhaust gas with a temperature of 200°C to 500°C into the packing layer. In the packing layer, a temperature-resistant section is provided at the tail gas inlet end, the height of the temperature-resistant section is greater than 1‰ of the total height of the packing layer, and the temperature-resistant section filler and structural materials can withstand a temperature of ≥200°C. The exhaust gas is washed with seawater in the washing device, and the seawater flow rate is selected as 200 within the range of the ratio of the engine exhaust flow rate to the seawater flow rate of 20 to 2000, wherein the unit of the engine exhaust flow rate is Nm 3 / h, the seawater flow unit is m 3 / h. The flow rate of the tail gas introduced in this embodiment is 10000Nm 3 / h, seawater flow is 50m 3 / h. The ...

Embodiment 3

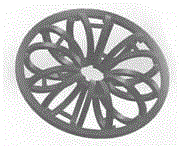

[0051] Embodiment 3: is a kind of optimized embodiment on the basis of embodiment 2. The dry packing factor is 20-1500 / m. When the dry packing factor is 30-1000 / m, or 40-500 / m, it is another two different embodiments. Another example is: applications such as Figure 3a Shown is an embodiment of a garland filler, the dry filler factor of the filler piled into a filler layer is 30 to 300; the application is as Figure 3b An embodiment of a Pall ring packing is shown, and the dry packing factor of the packing stacked into a packing layer is 100-700.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com