Preparation method for micro-nano silver loaded active carbon for eliminating formaldehyde for long term under room temperature condition

A micro-nano silver, formaldehyde elimination technology, applied in catalyst activation/preparation, separation methods, chemical instruments and methods, etc., can solve the problem of high reaction temperature, achieve high decomposition rate, stable performance, increase adsorption rate and adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Put the Φ20mm and 50mm long honeycomb-formed activated carbon in ultrapure water and ultrasonically clean it three times (put the activated carbon into ultrapure water and clean it fully with an ultrasonic cleaner), and dry it at 60°C; Put it in 15% ammonia solution at a ratio of 5, take it out after soaking at room temperature for 1 hour, and dry it at 80°C; prepare a silver nitrate aqueous solution with a silver ion concentration of 100ppm, and use the mass ratio of activated carbon to silver nitrate aqueous solution as 1:100 Immerse the activated carbon in the silver nitrate aqueous solution, soak it at room temperature for 6 hours, take it out and dry it at 100°C. Wherein the loading amount of micro-nano silver is 0.0005% (wt).

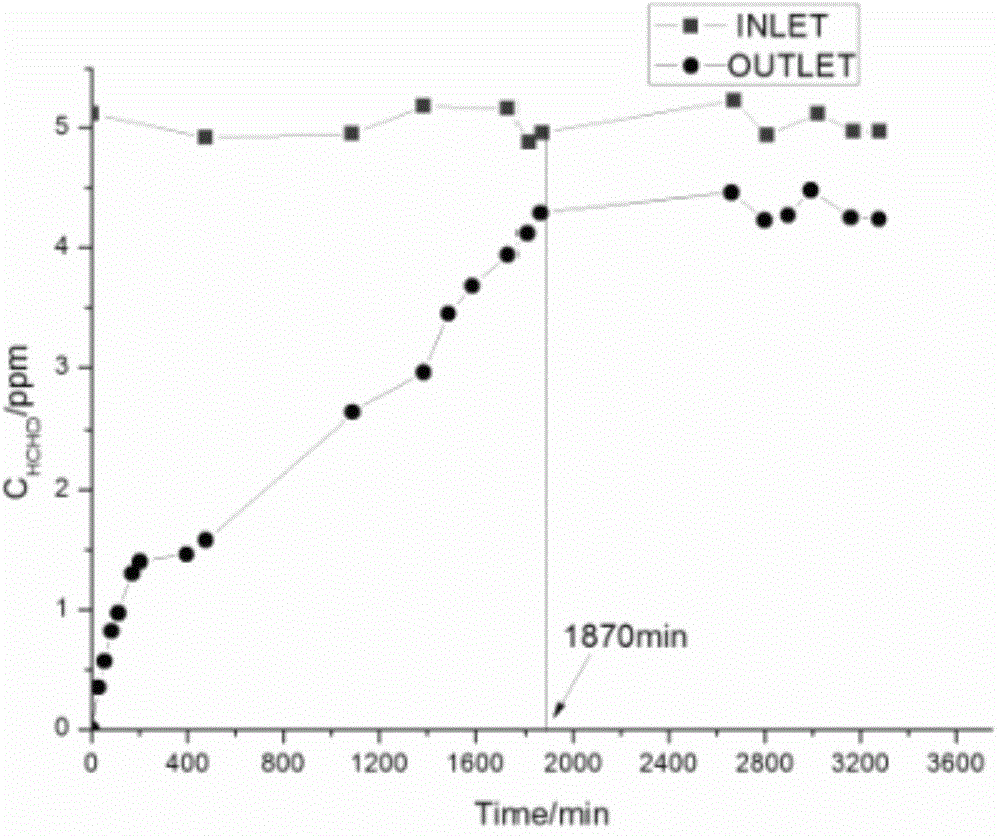

[0045] The formaldehyde purification performance of the prepared activated carbon was evaluated according to the aforementioned test conditions. At 25°C, the initial purification rate of formaldehyde was 100%. After 130 minutes, formaldehyd...

Embodiment 2

[0047] Put Φ20mm, length 50mm honeycomb-formed activated carbon in ultrapure water, ultrasonically clean it three times, and dry it at 80°C; place the cleaned activated carbon in 15% ammonia solution at a mass ratio of 1:10, and store it at room temperature Take it out after soaking for 24 hours, and dry it at 80°C; prepare a silver nitrate aqueous solution with a silver ion concentration of 70ppm, and impregnate the activated carbon in the silver nitrate aqueous solution with a mass ratio of activated carbon and silver nitrate aqueous solution of 1:50, and take it out after immersing for 48 hours at room temperature Dry at 60°C. Wherein the loading amount of micro-nano silver is 0.01% (wt).

[0048] The formaldehyde purification performance of the prepared activated carbon was evaluated according to the aforementioned test conditions. The initial purification rate of formaldehyde was 100% at 25°C. After 17 hours, formaldehyde began to penetrate, and after 75 hours, the formal...

Embodiment 3

[0050] Put the Φ20mm and 50mm long honeycomb-formed activated carbon in ultrapure water, ultrasonically clean it three times, and dry it at 80°C; place the cleaned activated carbon in 28% ammonia solution with a mass ratio of 1:20, and soak it at room temperature Take it out after 4 hours, and dry it at 100°C; prepare a silver nitrate aqueous solution with a silver ion concentration of 100ppm, and impregnate the activated carbon in the silver nitrate aqueous solution with a mass ratio of activated carbon and silver nitrate aqueous solution of 1:100, and take out 100 ℃ drying. Wherein the loading amount of micro-nano silver is 0.03% (wt).

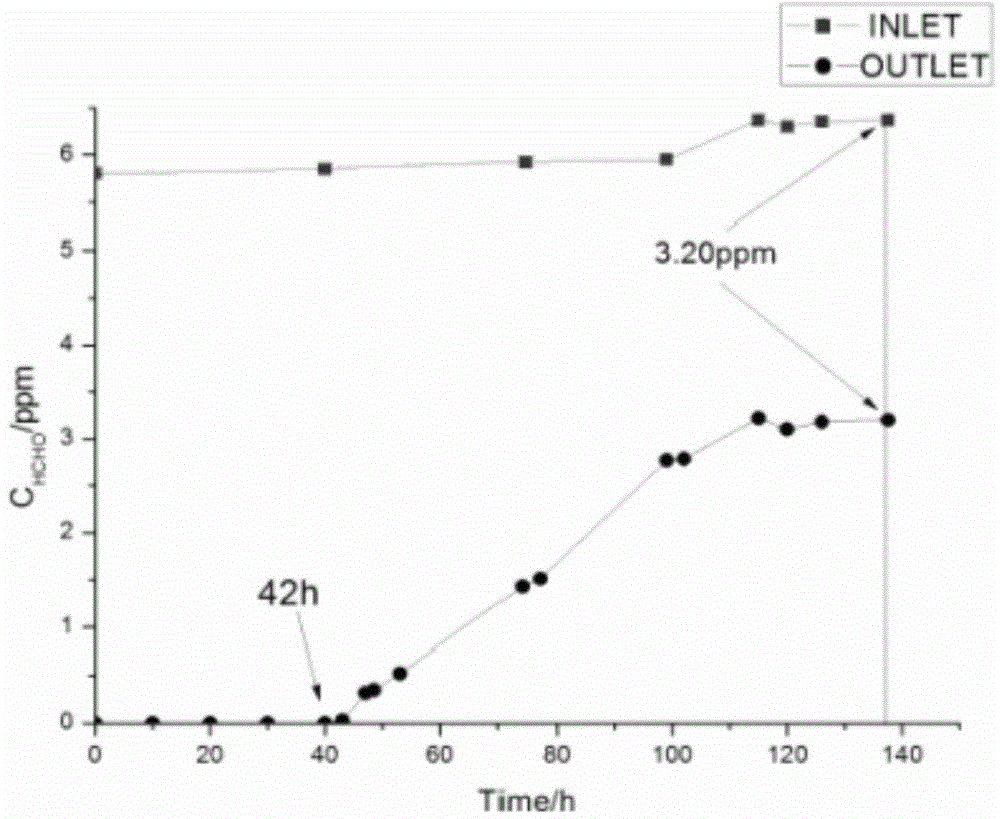

[0051] The prepared activated carbon was evaluated for formaldehyde purification performance according to the aforementioned test conditions. The breakthrough curve of activated carbon for formaldehyde purification is shown in the attached figure 2 As shown, the initial purification rate of formaldehyde is 100% at 25°C, formaldehyde begins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com