Gold-silicon oxide Janus structure nano particle with high catalytic characteristic and preparation method and application thereof

A gold nanoparticle and nanoparticle technology, which is applied to gold-silicon oxide Janus structure nanoparticles with high catalytic properties and its preparation and application fields, can solve the problem of unsuitable industrial catalytic applications and reduce the catalytic performance of gold-silicon oxide Janus structure nanoparticles. Responsibility and other issues, to achieve excellent reusability, conducive to industrial applications, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific embodiment one: The gold-silica Janus structure nanoparticle with high catalytic properties described in this embodiment is after ultraviolet lamp irradiates the gold-silica Janus structure nanoparticle with ethanol aqueous solution, centrifugal separation and water washing get.

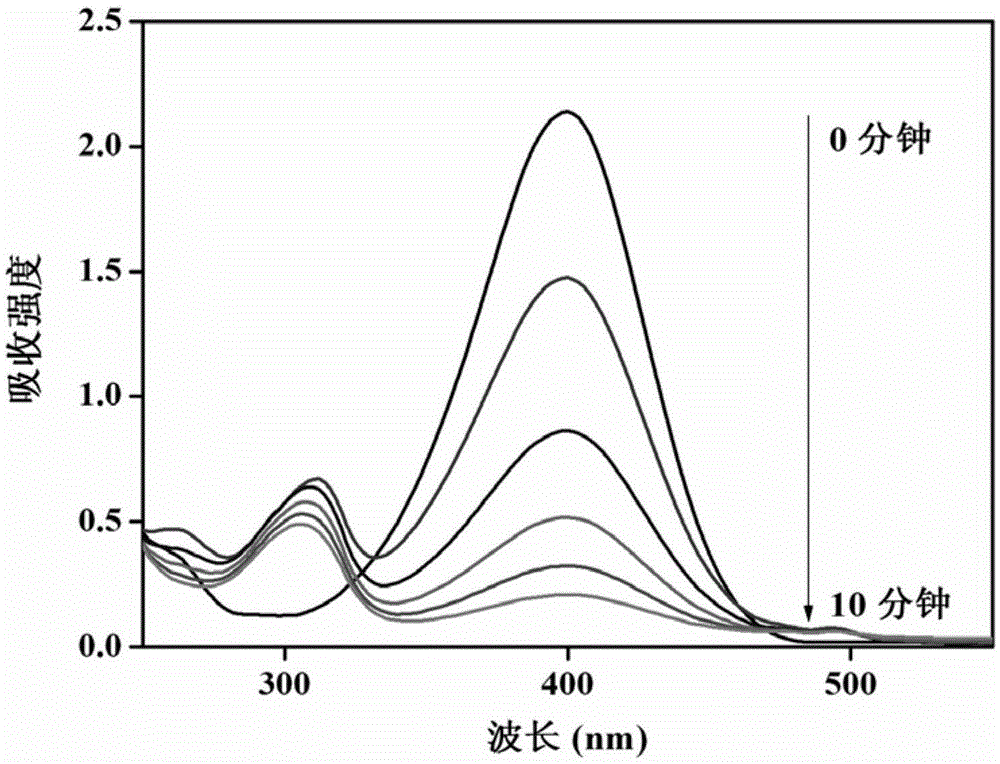

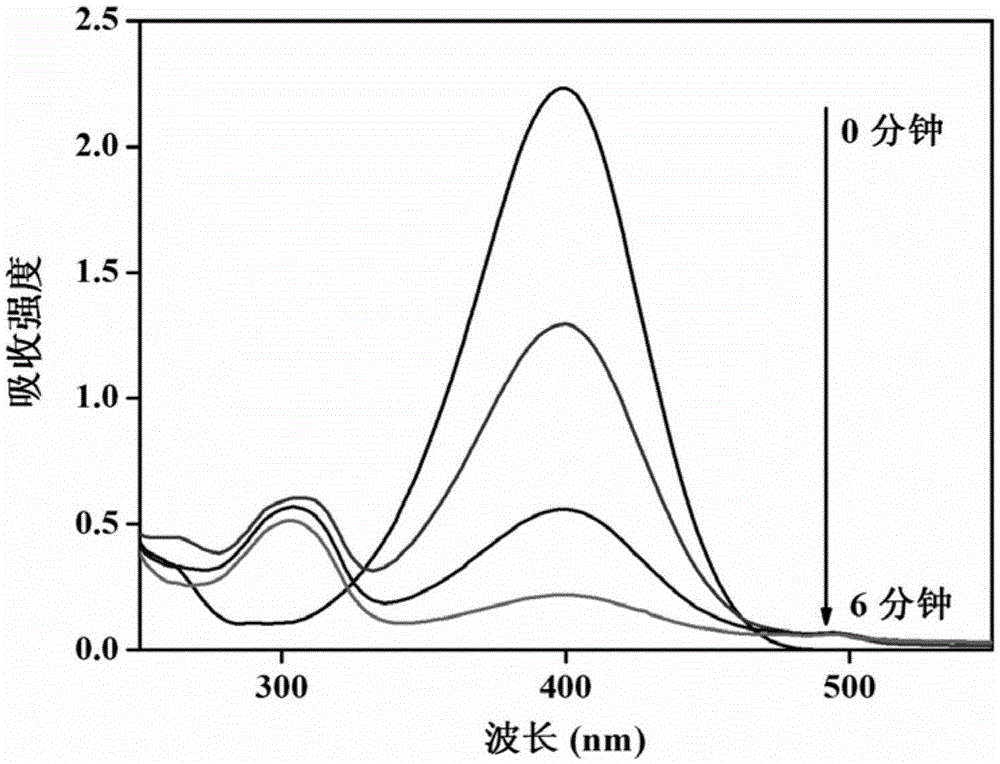

[0032] The beneficial effects of this embodiment are: (1) The catalytic properties of the gold-silica Janus structure nanoparticles are significantly enhanced, which is conducive to industrial applications; in the reduction reaction of nitrophenol, under the same conditions, the gold-oxidation before light The complete catalysis time of the silicon Janus structured nanoparticles is 10 minutes, and the light will cause the half-coated ligands on the gold surface to fall off, and part of the gold surface will be exposed, increasing the complete catalysis time of the Janus structured nanoparticles to 6 minutes. And whether it is light or not, the catalytic rate of Janus's gold-silica (0.24m...

specific Embodiment approach 2

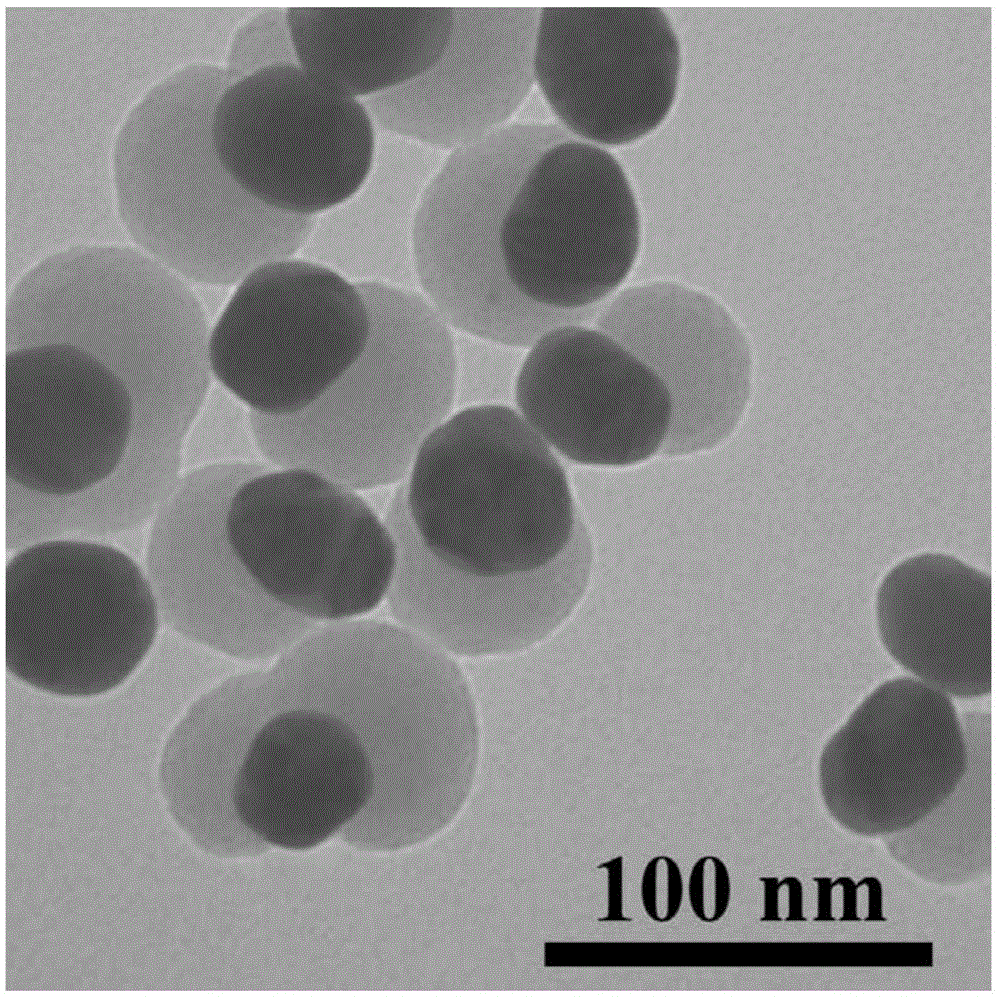

[0034] Specific embodiment two: this embodiment is different from specific embodiment one in that the gold-silica Janus structure nanoparticle ethanol aqueous solution is specifically prepared according to the following steps: 1. The particle size is 2 nm to 100 nm The gold nanoparticles are mixed with water to obtain a concentration of 10 -4 mmol / L~10 -3 mmol / L gold nanoparticle aqueous solution, drop the gold nanoparticle aqueous solution into the alcohol solvent to obtain the reaction system, and then mix the A solution with a concentration of 1mmol / L~10mmol / L under the condition of stirring at 50rpm~400rpm Drop the B solution with a concentration of 0.2mmol / L~5mmol / L into the reaction system. After the addition is complete, stir the reaction system for 1min~10min at a speed of 50rpm~400rpm, and then at a speed of 50rpm~400rpm Under stirring for 10 minutes to 60 minutes, a reaction system containing gold nanoparticles coated with dual ligands is obtained; the gold nanoparticl...

specific Embodiment approach 3

[0037] Specific embodiment three: This embodiment is different from one of specific embodiments one or two in that: the ultraviolet lamp is obtained after irradiating the gold-silicon oxide Janus structure nanoparticle ethanol aqueous solution, which is specifically carried out according to the following steps: At the speed of 50rpm~400rpm, the gold-silicon oxide Janus structure nano-particle ethanol aqueous solution was irradiated with a UV lamp with a power of 0.1W~1000W for 1min~1000min, and the ultrasonic power was 100W~500W. The irradiated gold-silica Janus structure nanoparticle ethanol aqueous solution is ultrasonically treated for 1min-100min, then centrifuged and washed with water for 3-6 times, and finally dispersed in water for use to obtain gold-silica with high catalytic properties Janus structured nanoparticles;

[0038] The ultraviolet lamp is one or a combination of single wavelength and continuous wavelength in ultraviolet light with a wavelength of 200 nm to 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com