Film transverse stretching device for slit type air port plenum chamber

A technology of transverse stretching and static pressure box, which is applied in the field of transverse stretching device of static pressure box film with slit type tuyere, which can solve the problem that the uniformity of the surface temperature of the stable film of hot air wind speed has not been substantially improved, and it cannot solve the problem of hot air. Arrived dead angle or hot air cross area, complex structure and other problems, to achieve the effect of uniform and stable temperature, improved appearance, and improved film roll flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

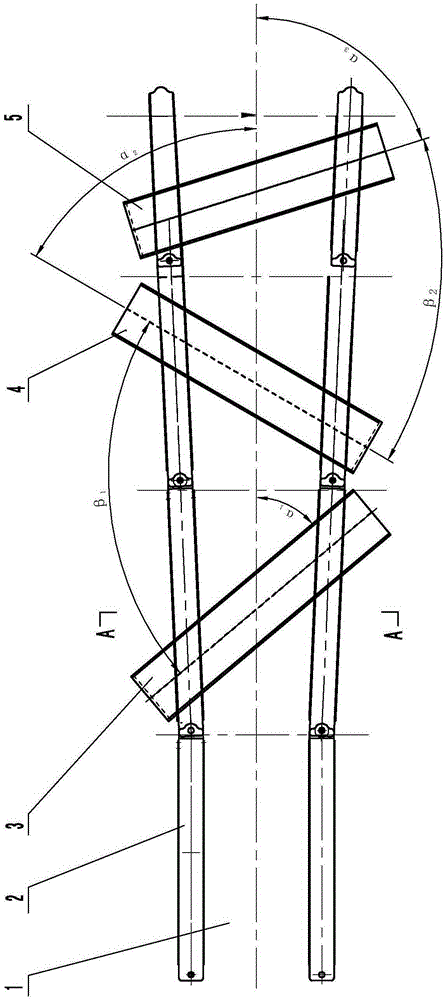

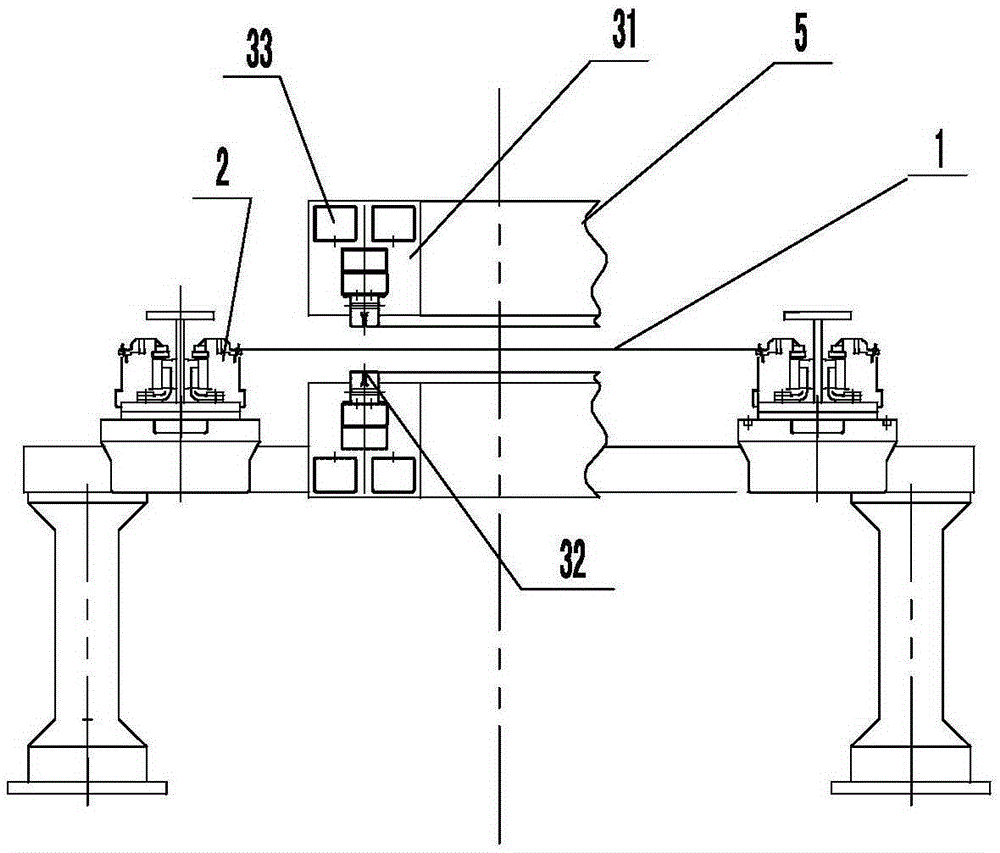

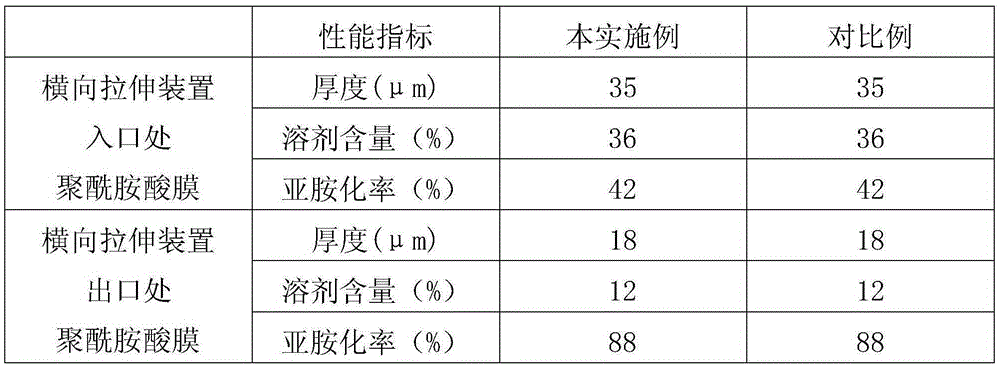

[0021] The embodiment structure of the slit-type tuyere static pressure box film transverse stretching device is as follows figure 1 and 2 shown. It includes the rails on both sides and the clip assembly 2 running on the rail. The clip assembly 2 clamps both sides of the film 1. The width at the entrance of the film 1 is 1050mm, the exit is 1180mm, and the stretch ratio is 1.12. In this example, the first stage to the third stage three-stage ovens are arranged along the traveling direction of the film 1, and a slit-type tuyere static pressure box is installed in each section of the oven. Up and down symmetrical straight slit tuyere 32, the width of slit tuyere 32 is 5mm. A plurality of return air outlets 33 are respectively distributed on the static plenum box body 31 on both sides of the slit tuyere 32 . The solvent content of the polyamic acid film at the entrance of the first-stage slit-type plenum plenum box 3 of the device is 36%, and the included angle α 1 =36°, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com