Process for treating printing and dyeing wastewater containing reactive dyes in advance

A technology for printing and dyeing wastewater and reactive dyes, applied in the field of water treatment, can solve the problems of difficult decolorization treatment, poor biodegradability, poor treatment effect, etc., and achieve the effect of simple operation, high removal rate and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

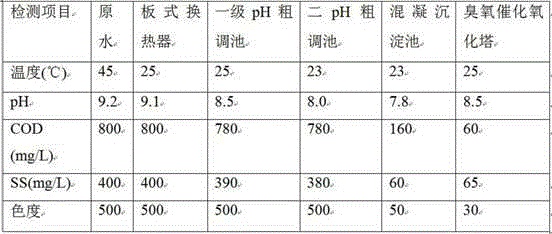

Embodiment 1

[0024] For the treatment of wastewater from an active printing and dyeing factory in Guangdong, the treatment process is as follows:

[0025] (1) Plate heat exchanger

[0026] The printing and dyeing wastewater containing reactive dyes first enters the plate heat exchanger for cooling, and the circulating cooling water of the plate heat exchanger is industrial water;

[0027] (2) Coagulation sedimentation tank

[0028] The printing and dyeing wastewater of reactive dyes is cooled by the plate heat exchanger and then enters the coagulation sedimentation tank. Add 200mg / L basic aluminum chloride and 2mg / L anionic polyacrylamide to the coagulation tank one by one, mix the chemicals with printing and dyeing wastewater containing reactive dyes, and enter the multi-channel folding plate coagulation tank with a hydraulic retention time of 15 minutes;

[0029] (3) Secondary pH adjustment pool

[0030] The printing and dyeing wastewater containing reactive dyes passes through the co...

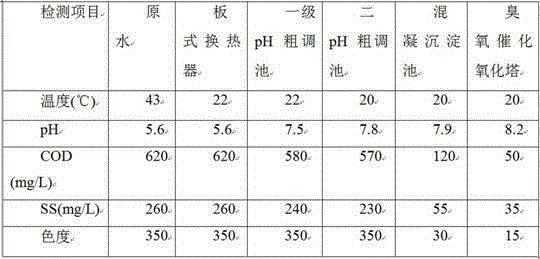

Embodiment 2

[0037] The treatment process of wastewater from an active printing and dyeing factory in Zhejiang is as follows:

[0038] (1) Plate heat exchanger

[0039] The printing and dyeing wastewater containing reactive dyes first enters the plate heat exchanger for cooling, and the circulating cooling water of the plate heat exchanger is industrial water;

[0040] (2) Coagulation sedimentation tank

[0041] The printing and dyeing wastewater containing reactive dyes is cooled by a plate heat exchanger and then enters the coagulation sedimentation tank. Add 300mg / L basic aluminum chloride and 2.5mg / L anionic polyacrylamide to the coagulation tank one by one. After mixing the chemicals and printing and dyeing wastewater containing reactive dyes, they enter the multi-channel folding plate coagulation tank, and the hydraulic retention time is 10 minutes;

[0042] (3) Secondary pH adjustment pool

[0043]The printing and dyeing wastewater containing reactive dyes passes through the coag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com