Organic fertilizer and preparation technology thereof

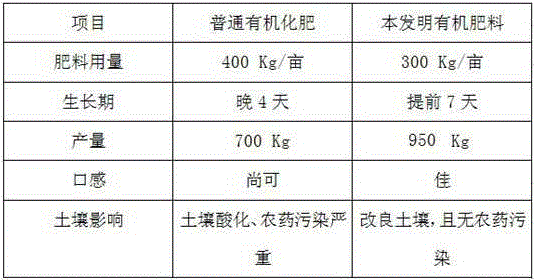

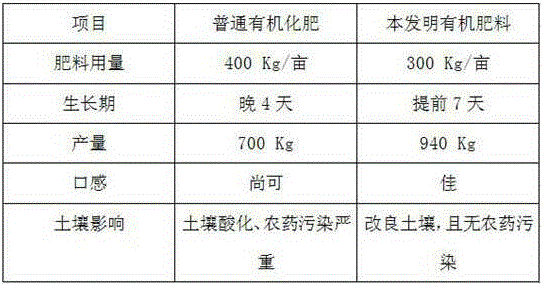

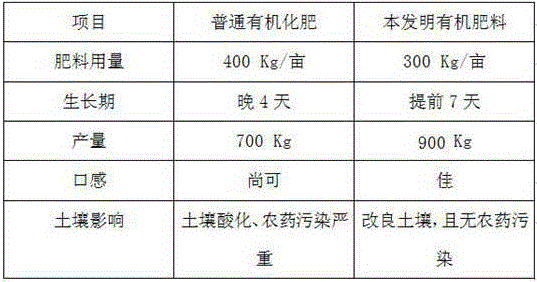

A technology of organic fertilizer and preparation process, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of easy lodging of crops, dry and hot wind, poor drought resistance, waste of straw resources, etc., and achieve low input, promote fruiting and early maturity , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] 15 parts of rice straw, 10 parts of corn straw, 10 parts of soybean straw, 5 parts of rapeseed meal, 6 parts of urea, 15 parts of diammonium phosphate, 10 parts of potassium dihydrogen phosphate, 5 parts of ferrous sulfate, 5 parts of manganese sulfate, 15 parts of cow manure, 20 parts of duck manure, 15 parts of chicken manure, 12 parts of pea flour.

[0010] Preparation method: Weigh each raw material according to the above weight parts, pulverize rice straw, corn straw and soybean straw with a pulverizer, pour them into a fermentation tank, add rapeseed cake, urea, diammonium phosphate, diammonium phosphate Potassium hydrogen sulfate, ferrous sulfate, manganese sulfate, pea flour, soaked for 60 hours, stirred evenly during the period, then added cow dung, duck dung and chicken manure to accumulate and ferment for 10 days, dried at low temperature after fermentation, and dried the mixture The powder is granulated into a spherical shape, and the finished product is bag...

Embodiment 2

[0015] 17 parts of rice straw, 12 parts of corn straw, 12 parts of soybean straw, 9 parts of rapeseed meal, 8 parts of urea, 16 parts of diammonium phosphate, 16 parts of potassium dihydrogen phosphate, 9 parts of ferrous sulfate, 9 parts of manganese sulfate, 18 parts of cow manure, 30 parts of duck manure, 17 parts of chicken manure, 16 parts of pea flour.

[0016] Preparation method: Weigh each raw material according to the above weight parts, pulverize rice straw, corn straw and soybean straw with a pulverizer, pour them into a fermentation tank, add rapeseed cake, urea, diammonium phosphate, diammonium phosphate Potassium hydrogen sulfate, ferrous sulfate, manganese sulfate, pea flour, soaked for 60 hours, stirred evenly during the period, then added cow dung, duck dung and chicken manure to accumulate and ferment for 10 days, dried at low temperature after fermentation, and dried the mixture The powder is granulated into a spherical shape, and the finished product is bag...

Embodiment 3

[0021] 20 parts of rice straw, 15 parts of corn straw, 15 parts of soybean straw, 15 parts of rapeseed meal, 9 parts of urea, 20 parts of diammonium phosphate, 20 parts of potassium dihydrogen phosphate, 10 parts of ferrous sulfate, 10 parts of manganese sulfate, 25 parts of cow manure, 40 parts of duck manure, 20 parts of chicken manure, 20 parts of pea flour.

[0022] Preparation method: Weigh each raw material according to the above weight parts, pulverize rice straw, corn straw and soybean straw with a pulverizer, pour them into a fermentation tank, add rapeseed cake, urea, diammonium phosphate, diammonium phosphate Potassium hydrogen sulfate, ferrous sulfate, manganese sulfate, pea flour, soaked for 60 hours, stirred evenly during the period, then added cow dung, duck dung and chicken manure to accumulate and ferment for 10 days, dried at low temperature after fermentation, and dried the mixture The powder is granulated into a spherical shape, and the finished product is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com