Oil shale and organic solid waste poly-generation utilization system and process thereof

A technology for organic solids and wastes, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, etc., to achieve the effects of wide adaptability, reduction of chemical pollution and thermal pollution, and increase of additional benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

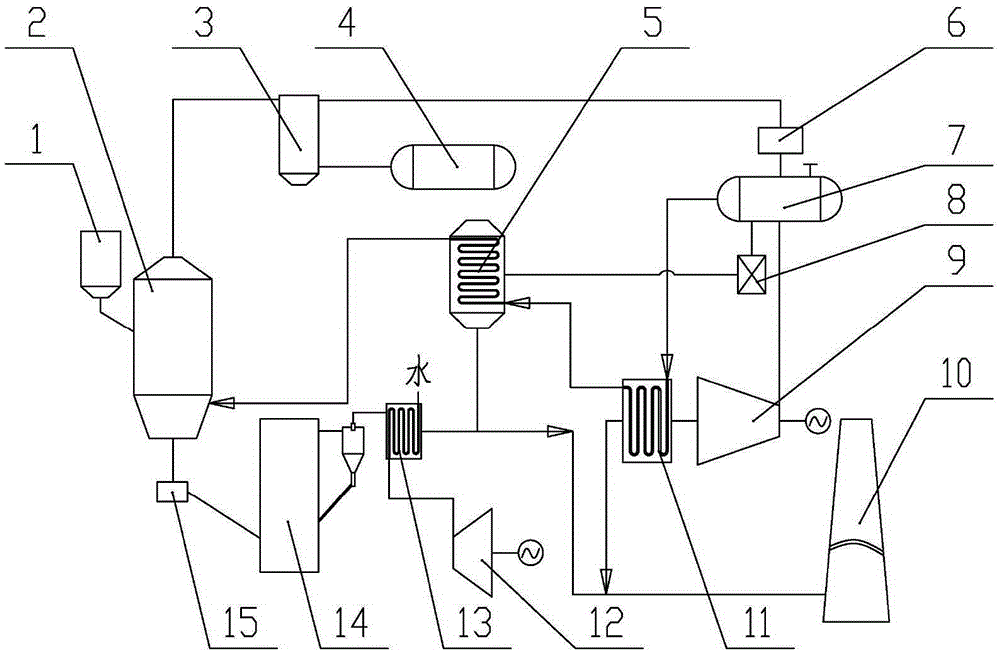

[0041] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0042] Such as figure 1As shown, the dried and crushed oil shale is mixed with organic solid waste in a certain proportion and then sent to silo 1, then descends into carbonization furnace 2, and low-temperature carbonization produces combustible gas, oil vapor and solid waste semi-coke. Combustible gas and oil vapor leave from the top of the carbonization furnace 2, and are separated into combustible gas and oil by the oil-gas separation device 3. The combustible gas is purified by the gas purification device 6 and stored in the gas storage tank 7, and the oil is stored in the oil tank 4; The feeder 15 enters the circulating fluidized bed boiler 14 for combustion; the gas storage tank 7 divides the combustible gas into three parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com