Antibacterial flame retardant clothing coating

A technology for coatings and clothing, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of easy to be contaminated with bacteria, easy to mildew, and affect the use effect, etc., to achieve convenient processing and use, improve product performance, and good flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

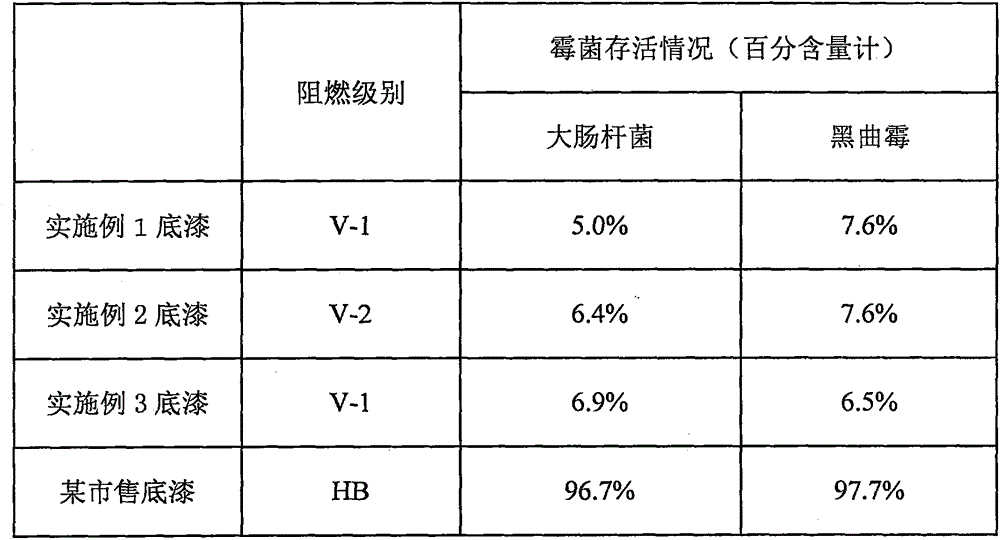

Examples

Embodiment 1

[0016] The antibacterial flame-retardant clothing coating in the present embodiment is made up of the component of following mass fraction: polyhydroxypropyl dimethyl ammonium chloride 42 parts, hydroxypropyl methylcellulose 44 parts, titanium dioxide 40 parts, ethyl alcohol 44 parts of diacid polyester, 40 parts of perchlorethylene resin, 44 parts of paraffin wax, 40 parts of talcum powder, 46 parts of polyvinyl butyral, 40 parts of tributoxyethyl phosphate, 44 parts of mica powder, corundum fine powder 40 parts, 44 parts of asbestos fiber, 40 parts of diethylene glycol butyl ether, 44 parts of nano-titanium dioxide, 40 parts of dioctyl phthalate, 44 parts of polyhexamethylene guanidine hydrochloride, 40 parts of hexamethylene diisocyanate, camphor 44 parts of wood flour, 40 parts of fatty acid glycerides, 44 parts of chlorothalonil, 40 parts of cellulose acetate micropowder, 1000 parts of water.

[0017] The steps of the above-mentioned antibacterial and flame-retardant clot...

Embodiment 2

[0022] The antibacterial flame-retardant clothing coating in the present embodiment is made up of the component of following mass fraction: polyhydroxypropyl dimethyl ammonium chloride 44 parts, hydroxypropyl methylcellulose 46 parts, titanium dioxide 42 parts, ethyl alcohol 46 parts of diacid polyester, 42 parts of perchlorethylene resin, 46 parts of paraffin, 42 parts of talcum powder, 48 parts of polyvinyl butyral, 42 parts of tributoxyethyl phosphate, 46 parts of mica powder, corundum fine powder 42 parts, 46 parts of asbestos fiber, 42 parts of diethylene glycol butyl ether, 46 parts of nano-titanium dioxide, 42 parts of dioctyl phthalate, 46 parts of polyhexamethylene guanidine hydrochloride, 42 parts of hexamethylene diisocyanate, camphor 46 parts of wood flour, 42 parts of fatty acid glycerides, 46 parts of chlorothalonil, 42 parts of cellulose acetate micropowder, 1500 parts of water.

[0023] The steps of the above-mentioned antibacterial and flame-retardant clothing...

Embodiment 3

[0028] The antibacterial and flame-retardant clothing coating in the present embodiment is made up of the following components in mass parts: 46 parts of polyhydroxypropyl dimethyl ammonium chloride, 48 parts of hydroxypropyl methylcellulose, 44 parts of titanium dioxide, ethyl 48 parts of diacid polyester, 44 parts of perchlorethylene resin, 48 parts of paraffin, 44 parts of talcum powder, 50 parts of polyvinyl butyral, 44 parts of tributoxyethyl phosphate, 48 parts of mica powder, corundum fine powder 44 parts, 48 parts of asbestos fiber, 44 parts of diethylene glycol butyl ether, 48 parts of nano-titanium dioxide, 44 parts of dioctyl phthalate, 48 parts of polyhexamethylene guanidine hydrochloride, 44 parts of hexamethylene diisocyanate, camphor 48 parts of wood flour, 44 parts of fatty acid glycerides, 48 parts of chlorothalonil, 44 parts of cellulose acetate micropowder, 2000 parts of water.

[0029] The steps of the above-mentioned antibacterial and flame-retardant c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com