Vermiculite and calcium silicate composite board capable of releasing negative oxygen ions and its production method

A negative oxygen ion, calcium silicate board technology, applied in chemical instruments and methods, building components, lamination and other directions, can solve the problems of low concentration and low negative oxygen ion rate, and achieve the effect of convenient disassembly, beautiful and noble appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

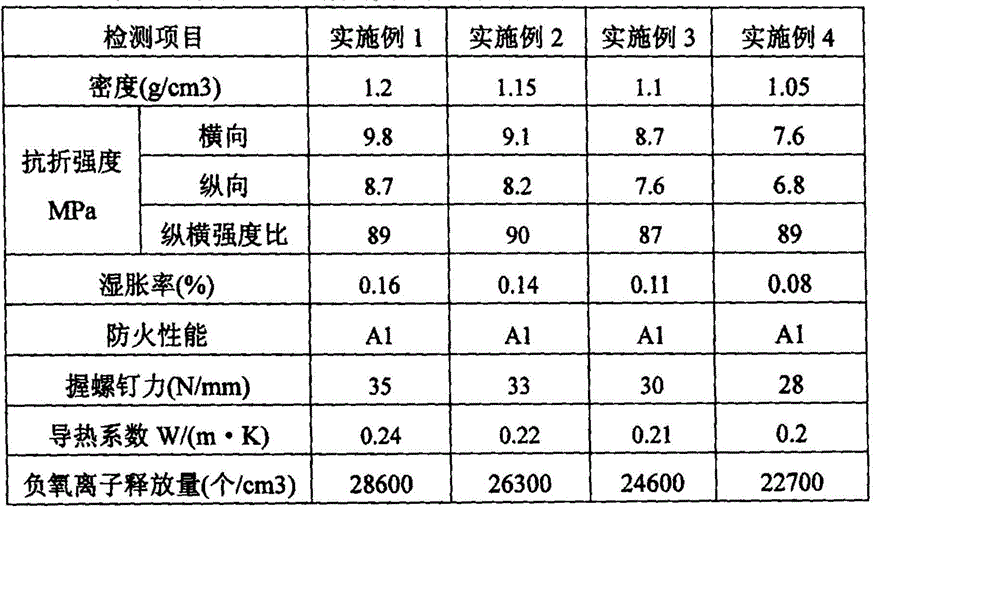

Examples

Embodiment 1

[0039] A vermiculite calcium silicate composite board capable of releasing negative oxygen ions, the composite board is a layer of vermiculite tourmaline mixed layer on a common calcium silicate board, the vermiculite tourmaline mixed layer is made of expanded vermiculite The stone, tourmaline and adhesive are mixed according to the weight ratio (10% of expanded vermiculite, 5% of tourmaline, and 85% of adhesive), and the mixed layer of vermiculite and tourmaline obtained is distributed on ordinary silicon Calcium Acid Board.

[0040] The specific steps of the secondary distributing method are as follows:

[0041] ① Use the batching system to make expanded vermiculite, tourmaline, adhesive, etc. into a uniform mixture according to the ratio;

[0042] ② After the ordinary calcium silicate board is formed by the head roller, a layer of the mixture in ① with thickness requirements is applied on the surface by coating process

[0043] ③Squeeze by cold press; maintain and dry.

...

Embodiment 2

[0046] A vermiculite calcium silicate composite board capable of releasing negative oxygen ions, the composite board is a layer of vermiculite tourmaline mixed layer on a common calcium silicate board, the vermiculite tourmaline mixed layer is made of expanded vermiculite The stone, tourmaline and adhesive are mixed according to the weight ratio (20% of expanded vermiculite, 4% of tourmaline, and 76% of adhesive), and the mixed layer of vermiculite and tourmaline obtained is distributed on ordinary silicon Calcium Acid Board.

[0047] The specific steps of the secondary distributing method are as follows:

[0048] ① Use the batching system to make expanded vermiculite, tourmaline, adhesive, etc. into a uniform mixture according to the ratio;

[0049] ② After the ordinary calcium silicate board is formed by the head roller, a layer of the mixture in ① with thickness requirements is applied on the surface by coating process

[0050] ③Squeeze by cold press; maintain and dry.

[...

Embodiment 3

[0054] A vermiculite calcium silicate composite board capable of releasing negative oxygen ions, the composite board is a layer of vermiculite tourmaline mixed layer on a common calcium silicate board, the vermiculite tourmaline mixed layer is made of expanded vermiculite Stone, tourmaline and adhesive are mixed according to the weight ratio (expanded vermiculite 30%, tourmaline 3%, adhesive, 67%), adopt the secondary distribution method, and the obtained vermiculite tourmaline mixed layer is distributed on ordinary silicon Calcium Acid Board.

[0055] The specific steps of the secondary distributing method are as follows:

[0056] ① Use the batching system to make expanded vermiculite, tourmaline, adhesive, etc. into a uniform mixture according to the ratio;

[0057] ② After the ordinary calcium silicate board is formed by the head roller, a layer of the mixture in ① with thickness requirements is applied on the surface by coating process

[0058] ③Cold press: curing and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com