Plate type heat pipe and novel pipeline

A plate type, heating tube technology, applied in the mechanical field, can solve the problems of easy leakage, bad products, waste, etc., and achieve the effects of good toughness, mass production, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

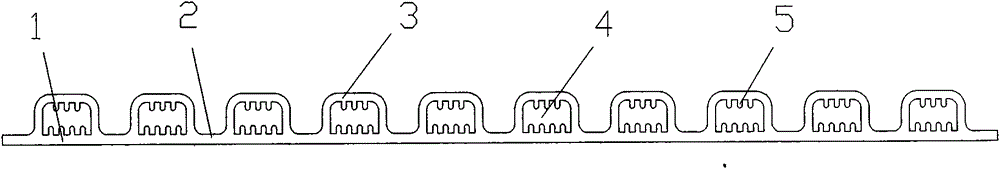

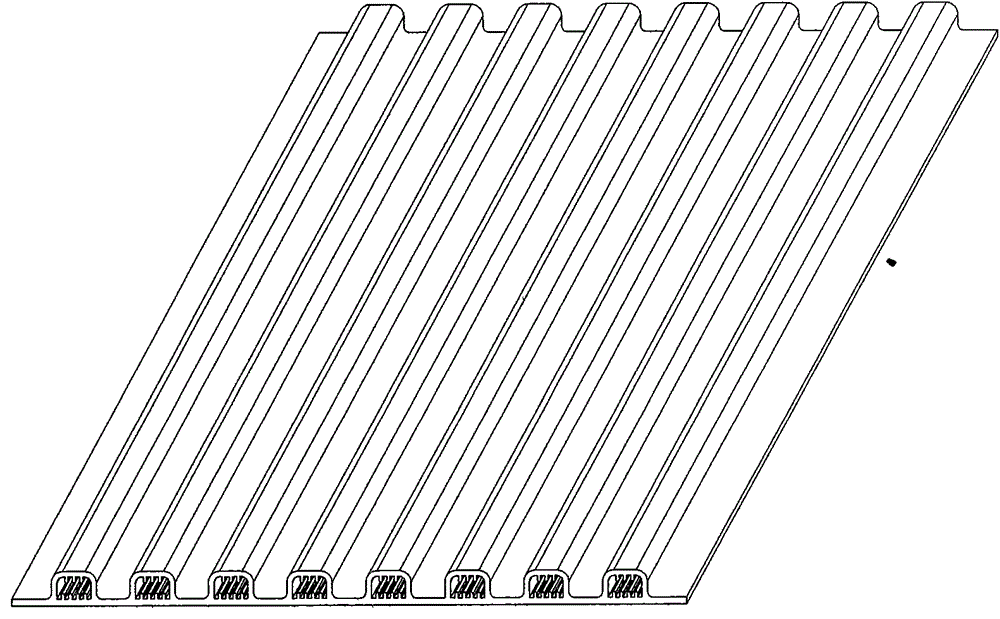

[0039] combine Figure 5 , embodiment two;

[0040] A plate heating tube, characterized in that it includes a pipe wall, the outer wall of the pipe wall contains more than one heat transfer channel 1, the inner wall of the heat transfer channel 1 contains capillary grooves 5, and the inside of the heat transfer channel 1 There is a heat transfer medium, and the capillary grooves 5 are raised strips. The substantive technical effect of the technical solution here is that when the pipeline here is used as a thermal insulation device, the original thermal insulation method of the thermal insulation cotton is changed in one fell swoop, but more than one external heat transfer channel 1 internal The heating liquid can be passed through, so that the pipeline becomes a real heating pipeline, rather than a simple passive insulation, and can be processed while being transported.

[0041] The outside can also be wrapped with a layer of insulation board.

[0042] combine Image 6 , e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com