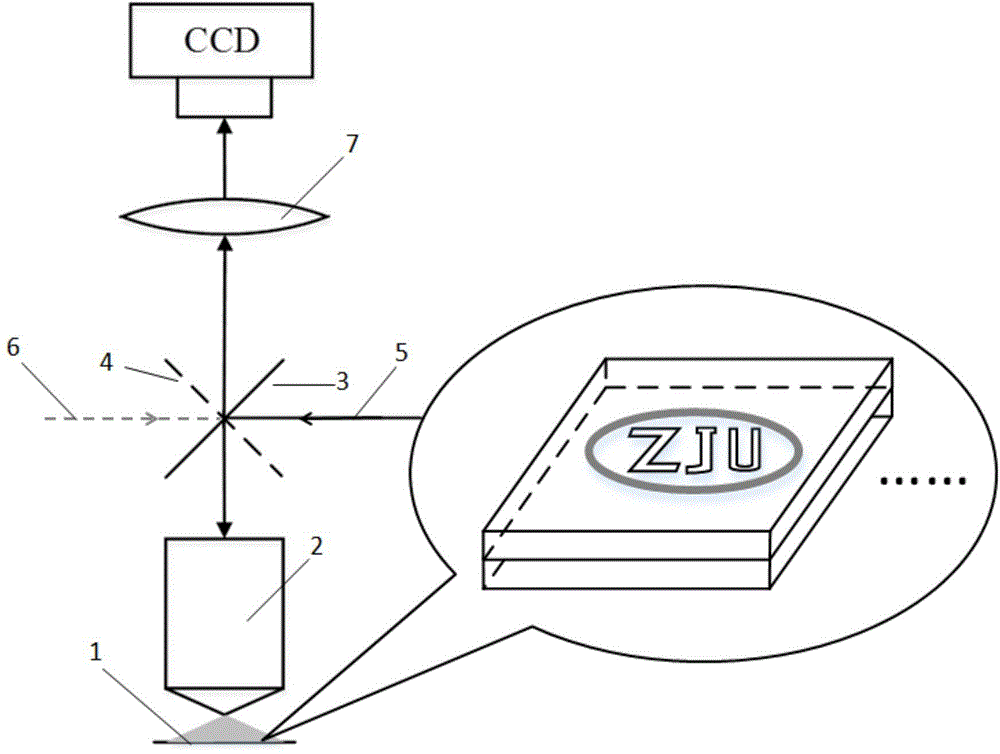

Multiple-scattering super-resolution microscopic method and apparatus under micro-nano illumination

A multiple scattering and micro-nano lighting technology, applied in the field of super-resolution microscopy, can solve the problems of limited resolution, expensive, complex follow-up processing, etc., and achieve the effect of no data processing, simple device, and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

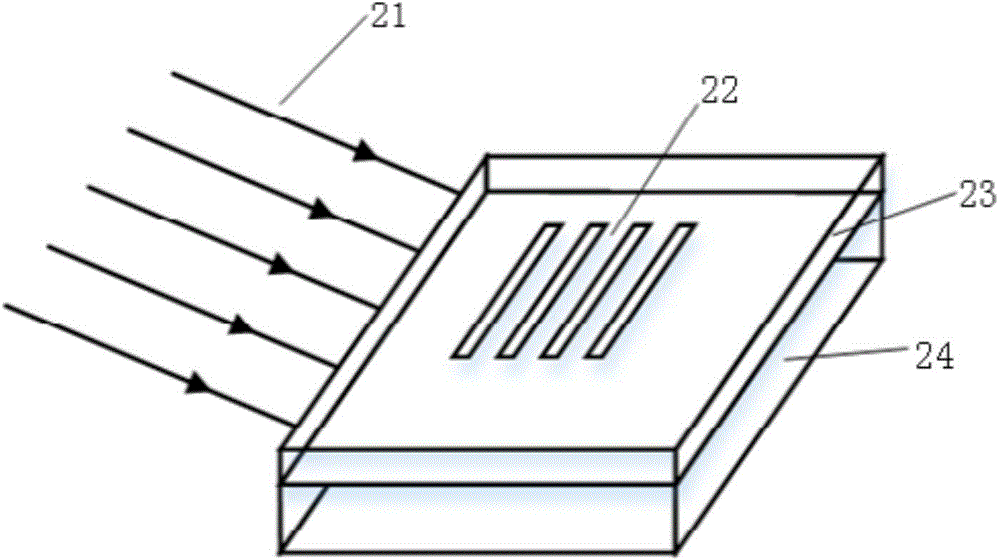

[0061] Such as figure 2 As shown, the slab waveguide is selected as the micro-nano light source in this embodiment, the sample 22 to be observed is placed on the slab waveguide with a thickness of 300 nanometers, the sample is located on the surface of the waveguide layer 23, the substrate is located at the bottom of the waveguide layer 23, and the substrate For the reflective layer 24, the light 21 with a wavelength of 500nm is coupled into the waveguide through a free optical path or an optical fiber bundle to form a micro-nano light source, and the coupled light can be in the visible or near-ultraviolet band.

[0062] In the process of waveguide surface field scattering, a magnified virtual image under the surface of the two-dimensional object will be formed. The whole device is observed under a high-power optical microscope, and the focus is adjusted to make the image clear. Use a 5 million pixel CCD to take pictures of the image, and process and restore the image in the ...

Embodiment 2

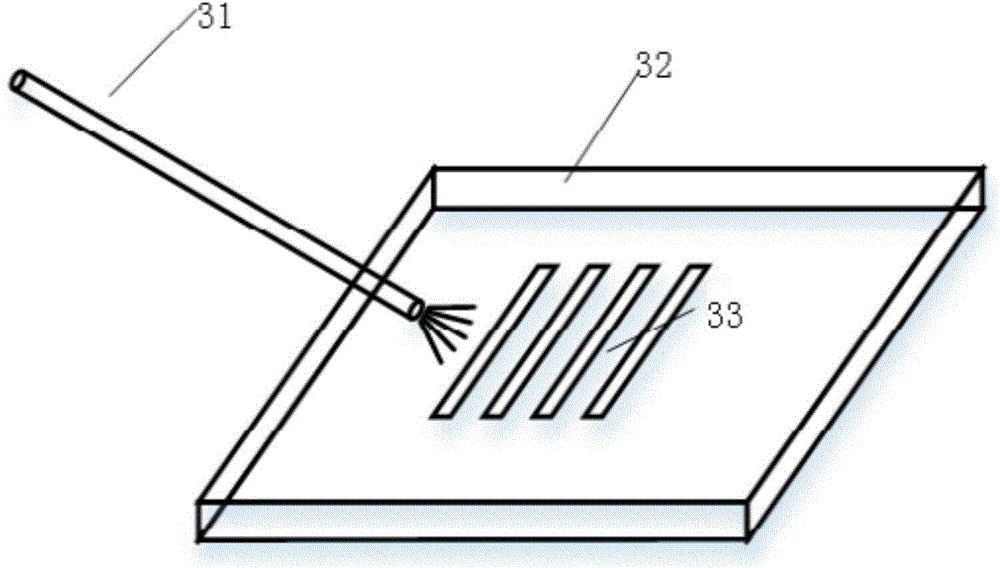

[0064] Such as image 3 As shown, a waveguide micro-nano fiber is used as the micro-nano light source in this embodiment, and the sample 33 is placed on the substrate 32 on the stage of a high-power optical microscope so that it is located near the focal plane of the objective lens. Fix the micro-nano optical fiber 31 on the precision three-dimensional translation stage, and approach it in a direction that forms an angle of 7 degrees with the horizontal plane (determined according to the height of the microscope stage and the height of the three-dimensional translation platform on which the micro-nano optical fiber is fixed, with a uniform illumination effect) sample. The laser or broadband light emitted by the external light source is coupled into the micro-nano fiber 31 . The distance between the micro-nano fiber 31 and the sample 33 is adjusted so that the target is illuminated by the light emitted by the micro-nano fiber, and the focus is adjusted slightly to make the ima...

Embodiment 3

[0068] Such as Figure 4 As shown, a combination of nanowires and a double-layer substrate is used to introduce a double optical path as the micro-nano light source in this implementation, the excitation light is coupled into the microscope illumination optical path, and the sample 43 is placed on a silicon-based silicon dioxide substrate 42 or embedded To the surface of the substrate, the bottom of the substrate is a reflective layer 44, and the thickness of the silicon dioxide layer is 300 nanometers. The substrate 42 is placed under a high-power optical microscope, so that the sample 43 is located on the focal plane of the objective lens. Using a micro-nano fiber connected to a three-dimensional precision stage (such as Figure 7 shown), perform three-dimensional micro-nano operations on the nanowire 41, place a CdS-doped nanowire with a diameter of 300 nanometers on the substrate near the sample 43, and bend the nanowire 41 according to the contour of the sample 43. The n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com