Missile-borne conformal microstrip antenna

A microstrip antenna and missile-borne technology, which is applied in the field of missile-borne conformal microstrip antennas, can solve the problems of affecting the electrical performance of the antenna, the deterioration of positioning time and positioning accuracy, and achieve the purpose of avoiding breakage, improving aerodynamic performance and structural reliability, The effect of improving structural reliability and ammunition aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

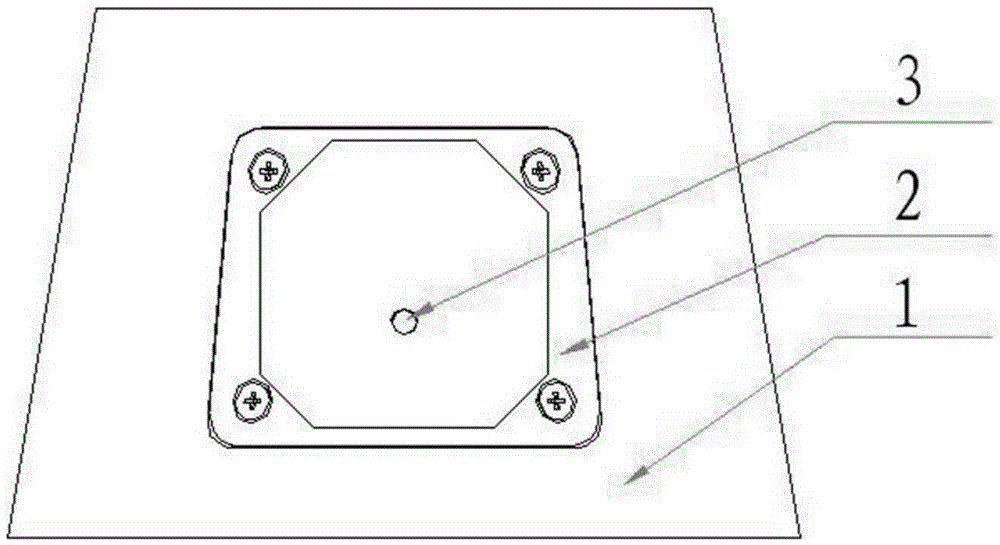

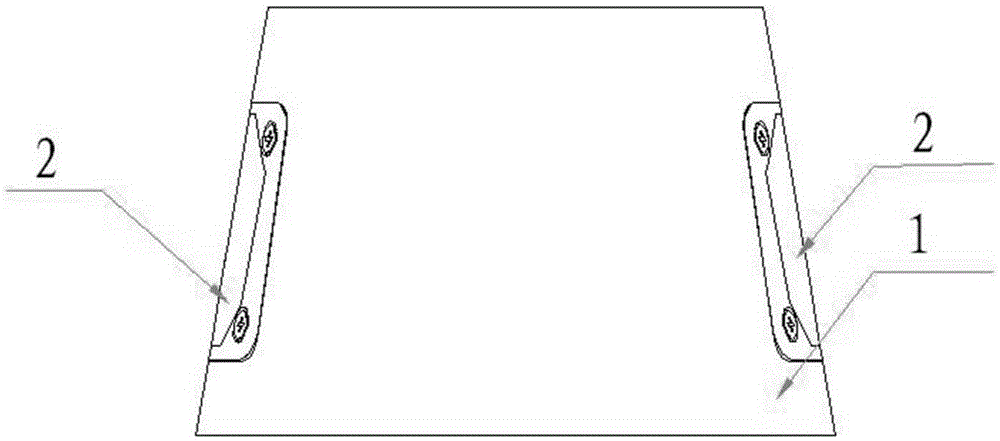

[0038] Such as Figure 1—Figure 5f As shown, the present invention is a missile-borne conformal microstrip antenna, including a first tapered cavity 1 and a first conformal microstrip antenna 2, and the inner wall of the tapered cavity is equipped with electrical devices, such as a low-noise amplifier circuit Wait. A plurality of first conformal slots 1-1 can be arrayed in the axial direction of the tapered cavity, and the conformal microstrip antenna is fixed at the bottom of the conformal slot by conductive glue bonding or screw connection; in this embodiment, the first The tapered cavity arrays 2 conformal slots along the axis, the array angle is 180°, and 4 M2 threaded through holes 1-2 are drilled at the bottom of the conformal slots to lock the conformal microstrip antenna. Electrical devices, such as low noise amplifier circuits, are installed on the inner wall of the tapered cavity.

[0039] The shape of the first conformal microstrip antenna is designed with referen...

Embodiment 2

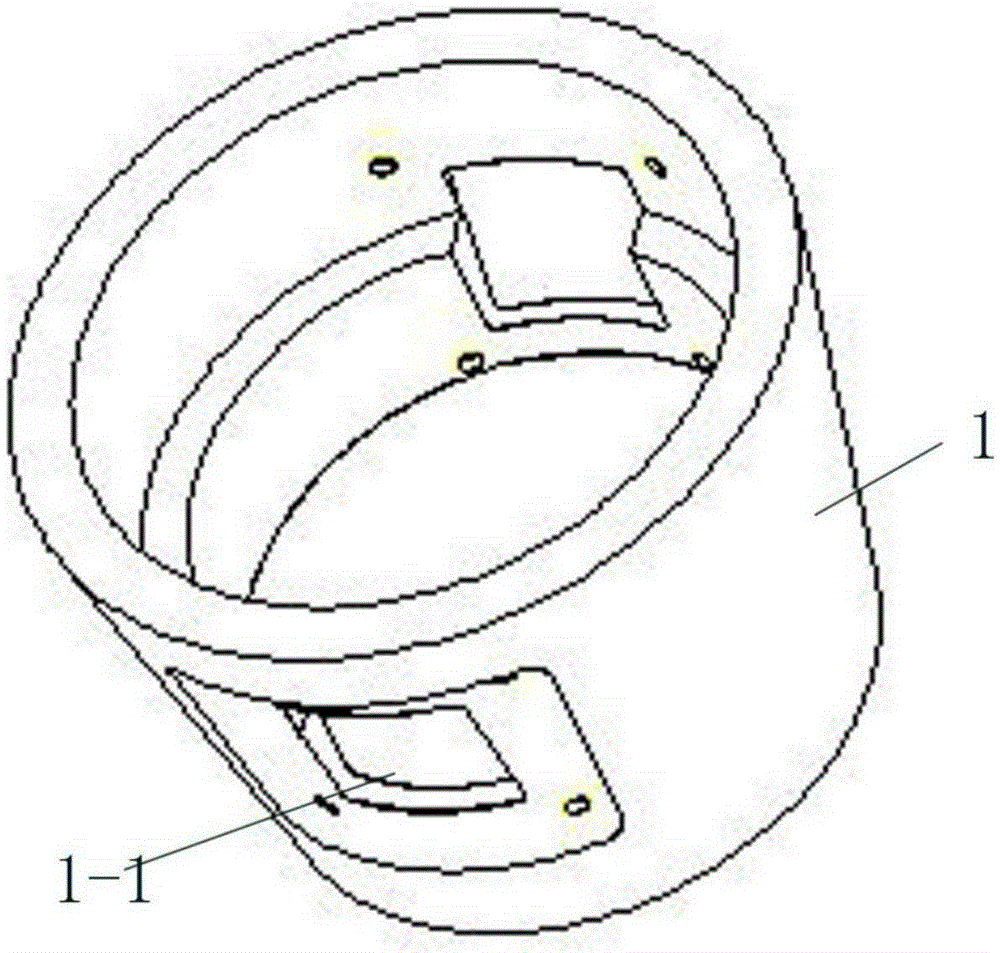

[0041] Such as Figure 6a-Figure 8c As shown, the missile-borne conformal microstrip antenna according to Embodiment 2 of the present invention includes a second tapered cavity 4 and a plurality of second conformal microstrip antennas 5, and multiple The second conformal slot 4-1, the bottom of the conformal slot can be fixed with conductive adhesive or threaded connection; in this embodiment, the second tapered cavity arrays three conformal slots along the axis , the array angle is 120°, because the size of the second conformal microstrip antenna 5 is exactly one third of that of the second tapered cavity 4, so the second conformal slots 4-1 are connected together to form an annular slot , 12 M2 through holes 4-2 are drilled at the bottom of the annular groove to lock three second conformal microstrip antennas.

[0042]The shape of the second conformal microstrip antenna 5 is designed with reference to the radian of the second tapered cavity, and the surface of the antenna i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com