Complex enzyme feed additive and application thereof

A feed additive and compound enzyme technology, applied in application, animal feed, animal feed, etc., can solve the problems of rising feed-to-meat ratio, increasing feed cost, low feed conversion rate, etc. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

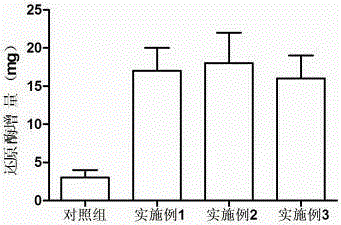

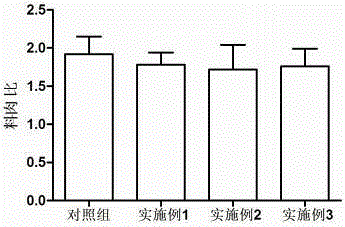

Embodiment 1

[0025] A broiler feed processed from new corn contains the following components by weight: 56.9 parts of corn, 4.7 parts of common flour, 18.8 parts of soybean meal, 2.5 parts of cotton meal, 2.3 parts of meat meal, 2 parts of peanut meal, 1.5 parts of corn gluten meal, 5 parts of corn DDGS, 1 part of feather meal, 0.5 part of oil, 1.3 parts of flour powder, 1.5 parts of calcium hydrogen powder, 1.5 parts of chicken premix, 0.063 parts of compound enzyme feed additive.

[0026] The content of xylanase in the compound enzyme feed additive in the above formula is 40000U / g, the content of β-glucanase is 20000U / g, the content of β-mannanase is 3500U / g, and the content of cellulase is 10000U / g , the content of protease is 15000U / g, the content of amylase is 800U / g, the content of lipase is 5000U / g, and the content of carrier is 200mg / g.

[0027] Mix the components other than the compound enzyme evenly according to the above ratio to make granular feed, and add the compound enzyme b...

Embodiment 2

[0029] A broiler feed processed from new corn contains the following components by weight: 57.1 parts of corn, 6.4 parts of common flour, 13.1 parts of soybean meal, 3.6 parts of cotton meal, 3 parts of meat meal, 2.9 parts of peanut meal, 1.5 parts of corn gluten meal, 4.4 parts of corn DDGS, 1.3 parts of feather meal, 2.4 parts of oil, 1.1 parts of flour powder, 1.2 parts of calcium hydrogen powder, 2 parts of chicken premix, 0.067 parts of compound enzyme feed additive.

[0030] The content of xylanase in the compound enzyme feed additive in the above formula is 40000U / g, the content of β-glucanase is 20000U / g, the content of β-mannanase is 3500U / g, and the content of cellulase is 10000U / g , the content of protease is 15000U / g, the content of amylase is 800U / g, the content of lipase is 5000U / g, and the content of carrier is 200mg / g.

[0031] Mix the components other than the compound enzyme evenly according to the above ratio to make granular feed, and add the compound enzy...

Embodiment 3

[0033] A broiler feed processed from new corn contains the following components by weight: 61.7 parts of corn, 7.6 parts of common flour, 7 parts of soybean meal, 4.1 parts of cotton meal, 3 parts of meat meal, 2.9 parts of peanut meal, 2 parts of corn gluten meal, 2.1 parts of corn DDGS, 2.4 parts of feather meal, 3 parts of oil, 1.04 parts of flour powder, 1.16 parts of calcium hydrogen powder, 2 parts of chicken premix, 0.07 parts of compound enzyme feed additive.

[0034] The content of xylanase in the compound enzyme feed additive in the above formula is 40000U / g, the content of β-glucanase is 20000U / g, the content of β-mannanase is 3500U / g, and the content of cellulase is 10000U / g , the content of protease is 15000U / g, the content of amylase is 800U / g, the content of lipase is 5000U / g, and the content of carrier is 200mg / g.

[0035] Mix the components other than the compound enzyme evenly according to the above ratio to make granular feed, and add the compound enzyme bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com