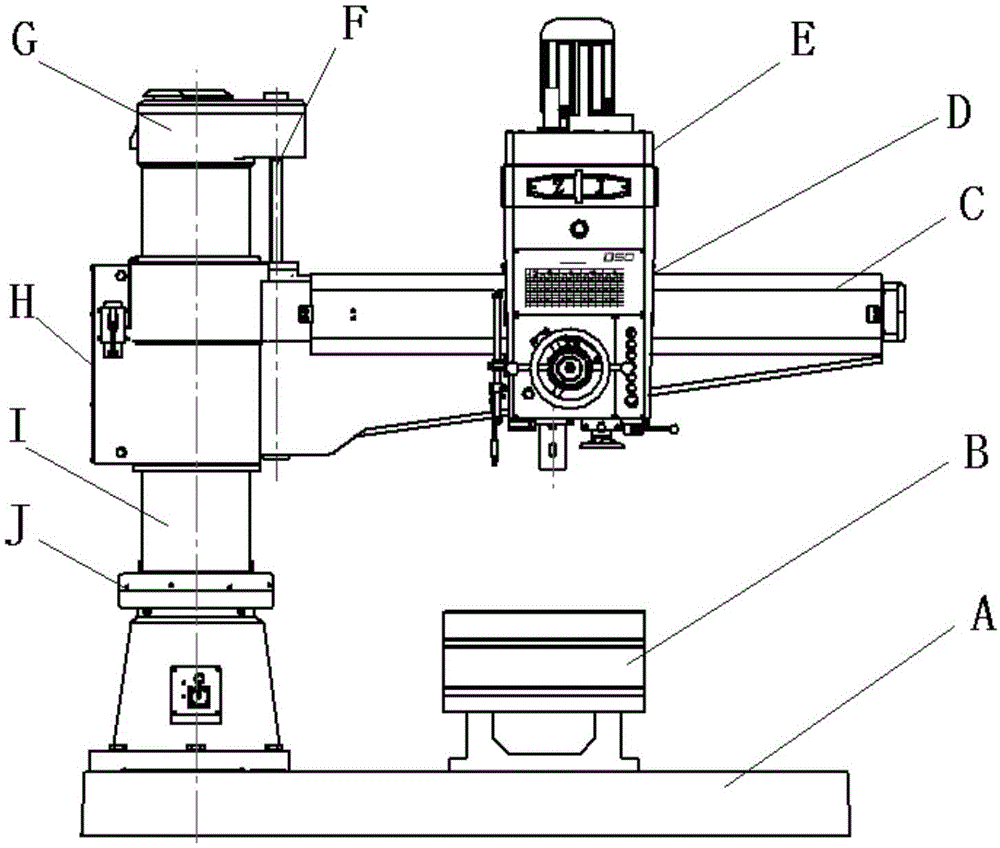

Radial drilling machine

A radial drilling machine and cross-arm technology, applied in the field of machine tools, can solve the problems of high environmental requirements for hydraulic components, long hydraulic clamping response time, short service life, etc., to achieve environmental protection, shorten production cycle, and service life short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a radial arm drilling machine, which includes a base, a worktable, a cross arm, a headstock clamping mechanism, a headstock, a cross arm lifting mechanism, a body shell, a cross arm clamping mechanism, a column, a column clamping mechanism, It is characterized in that: the radial arm drilling machine includes a transverse arm lifting mechanism, a transverse arm clamping mechanism, and a column clamping mechanism;

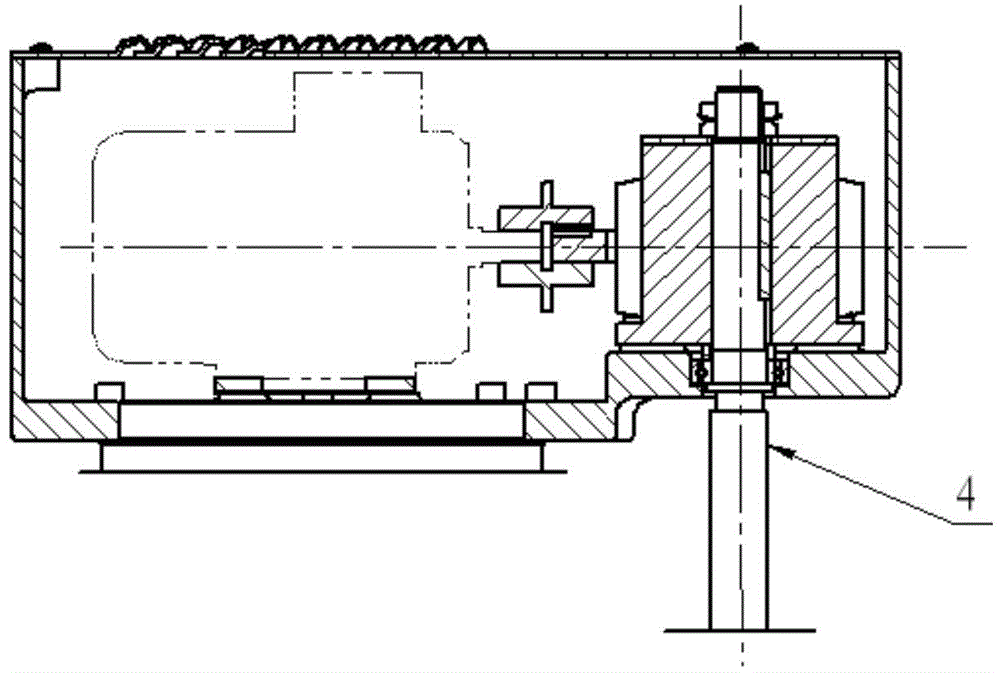

[0025] Among them: the cross arm lifting mechanism, including the three-phase AC motor 1, the coupling 2, the worm gear elevator 3, the lifting screw 4; the three-phase AC motor 1 is connected to the worm gear elevator 3 through the coupling 2, and the worm gear elevator 3 and the lifting wire The bar 4 is connected by a key and locked with a stop washer through two round nuts;

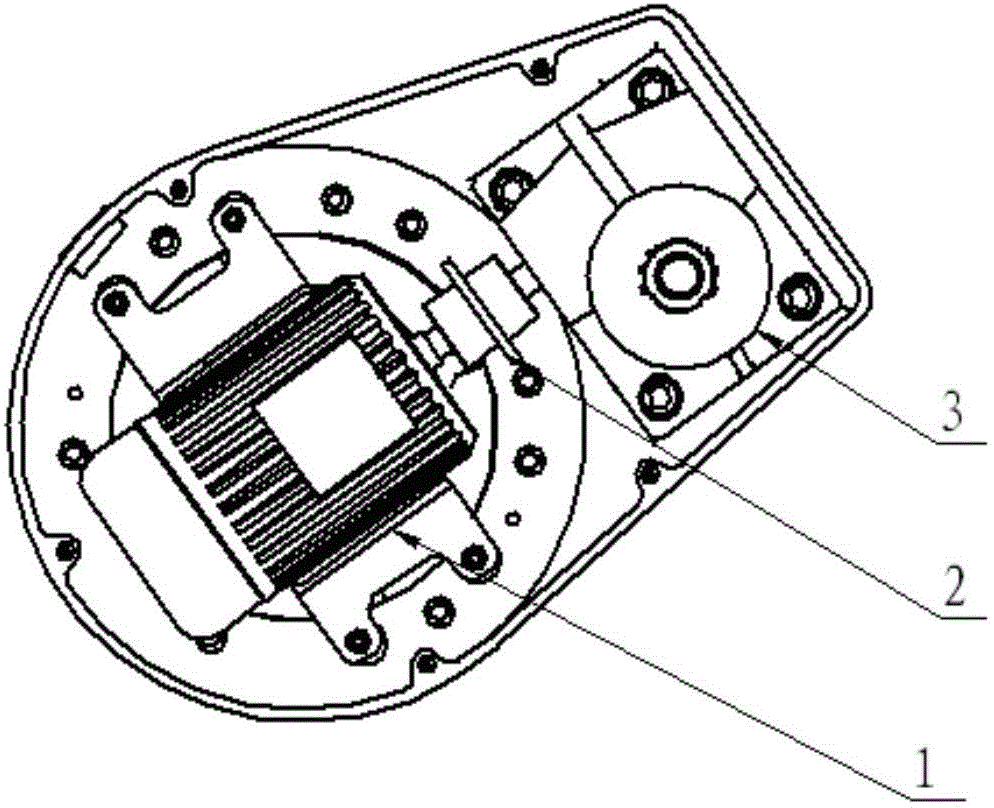

[0026] Cross arm clamping mechanism, including torque motor 5, through reducer 6, upper micro switch 7, push block 8, lower micro switch 9, clamping lever 10, fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com