Laser cladding and adaptive milling integrated compound CNC machine tool for blade repair

A composite CNC machine tool and laser cladding technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of large grinding allowance, hard-to-fuse surfacing layer of blades, and difficult-to-remove material allowance processing, etc., to achieve Improve processing efficiency and precision, save equipment procurement costs, and facilitate intelligent management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing. Embodiments of the present invention include, but are not limited to, the following examples.

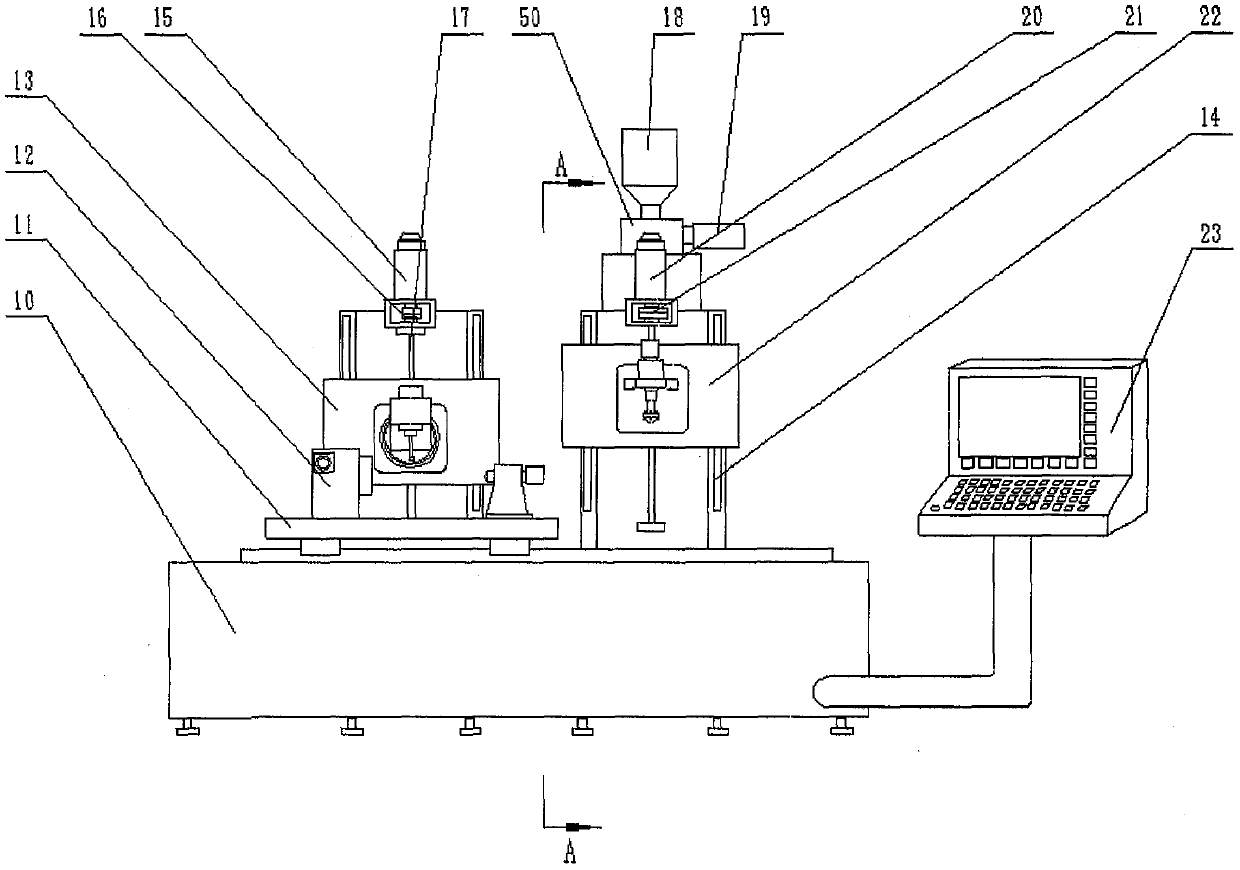

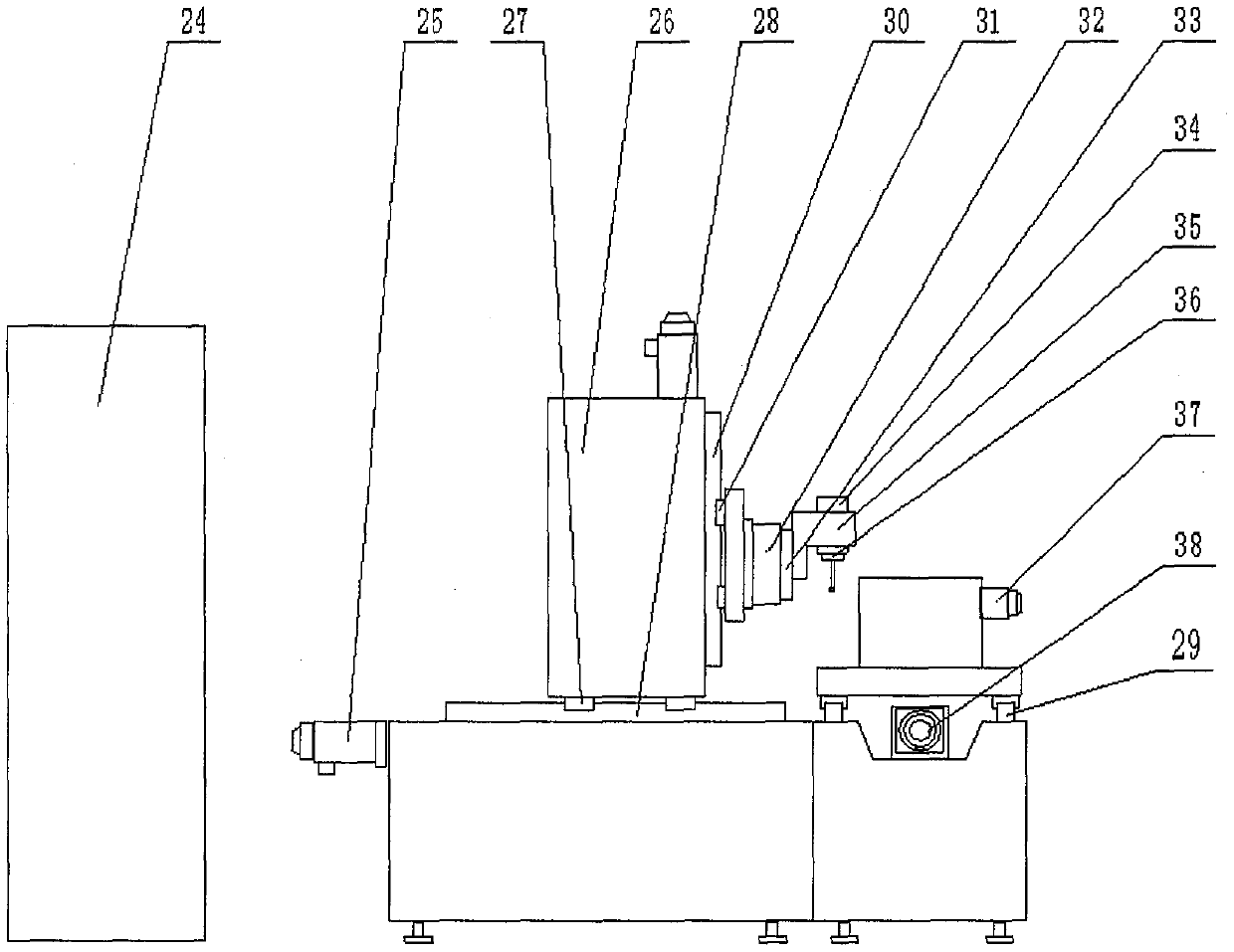

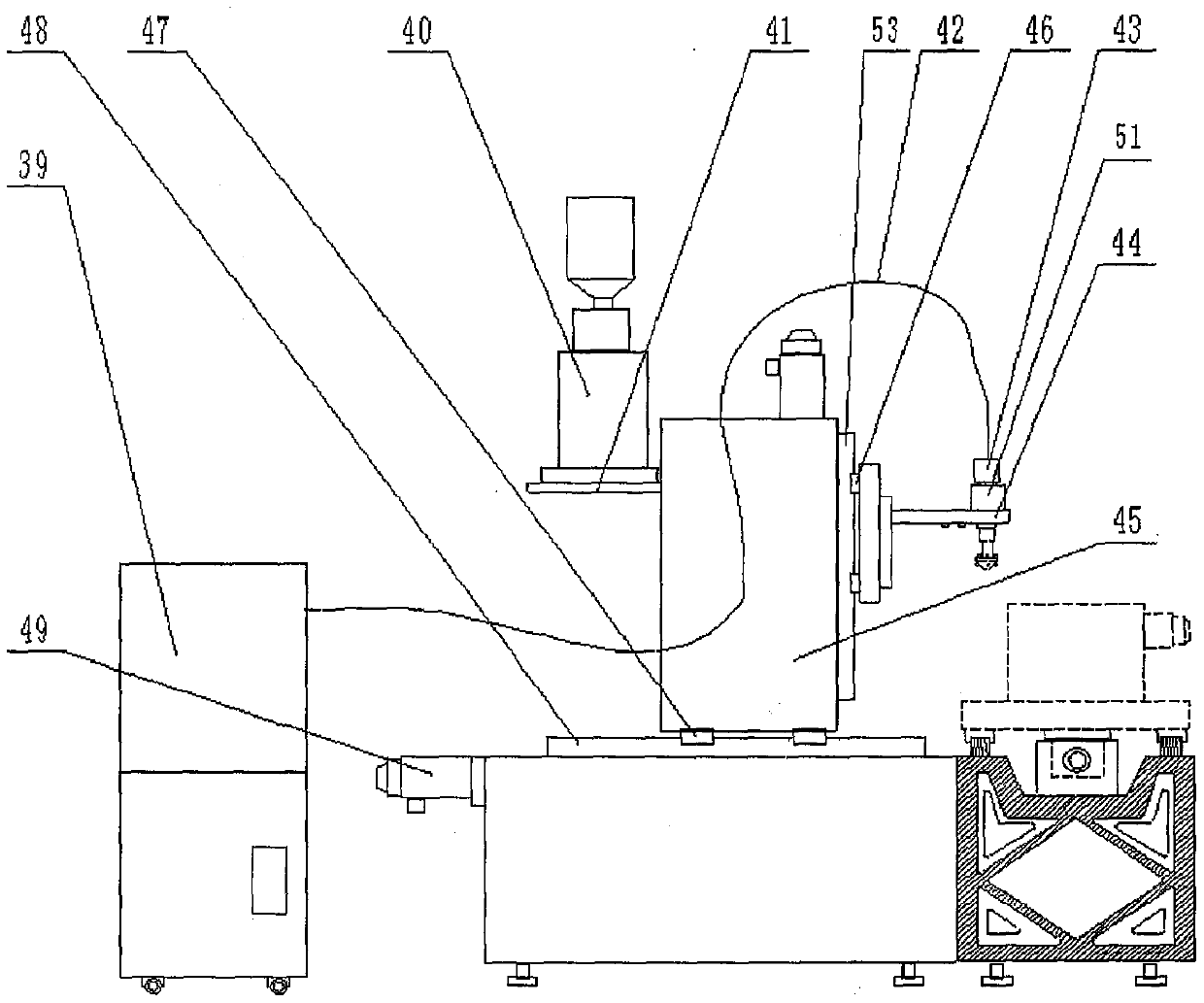

[0034] Such as figure 1 , figure 2 , image 3 As shown, it is the front view, side view and A-A view of a preferred example of the laser cladding and adaptive milling integrated CNC machine tool for blade repair of the present invention. It mainly includes installing a first column (26) for realizing milling and a second column (45) for laser cladding surfacing on the double T-shaped bed (10), which is arranged at one end of the bed and driven by a servo motor (38 ) to drive the sliding table to achieve X-direction movement. The rotary table (12) installed on the sliding table is driven by the A-direction servo motor (37) to realize continuous 360° rotary motion, and the blade (2) to be repaired is installed on the fixture (1) arranged on the working end of the rotary table , i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com