An electric vehicle air conditioner silicone rubber heating film heater

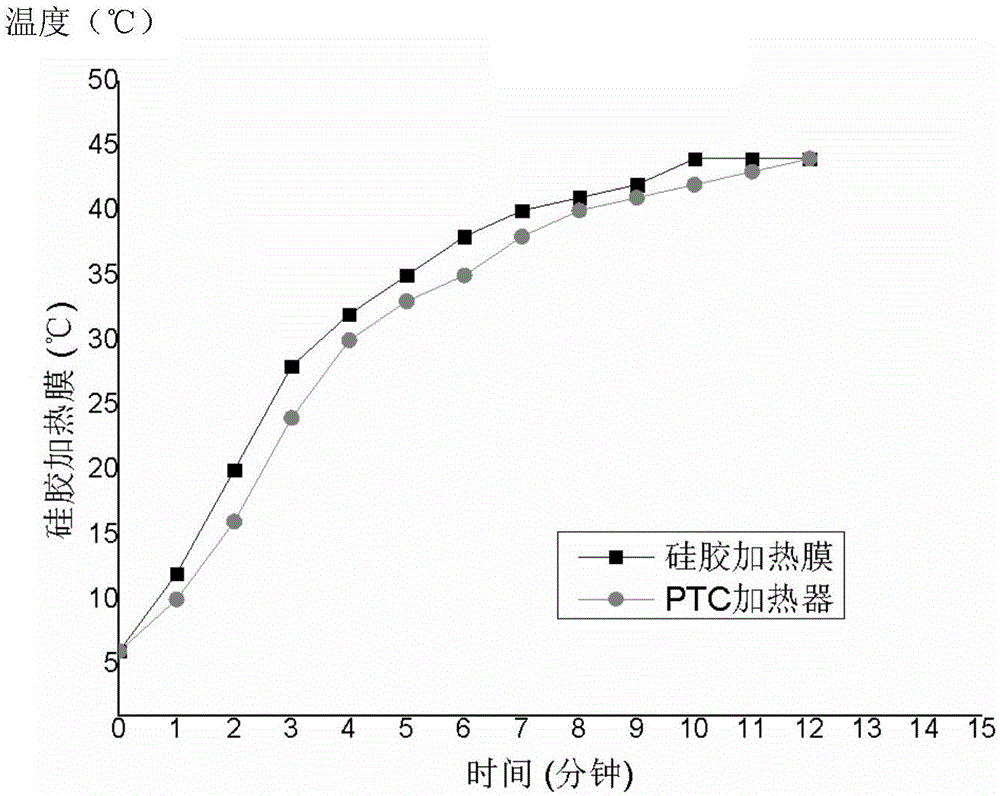

A silicone heating film, electric vehicle technology, applied in heating/cooling equipment, vehicle parts, air treatment equipment, etc., can solve the problems of low heat conversion efficiency of PTC heaters, increased power consumption of electric vehicles, difficult disassembly and repair, etc. Achieve the effects of improving heating comfort, simple structure, and easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

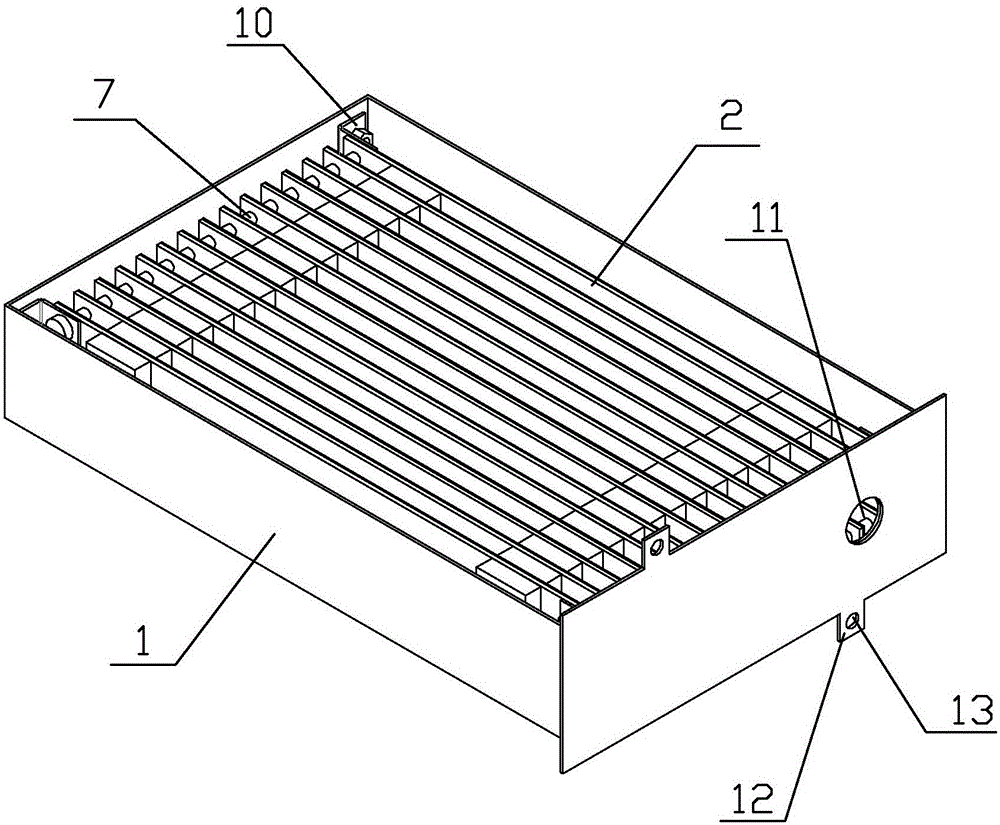

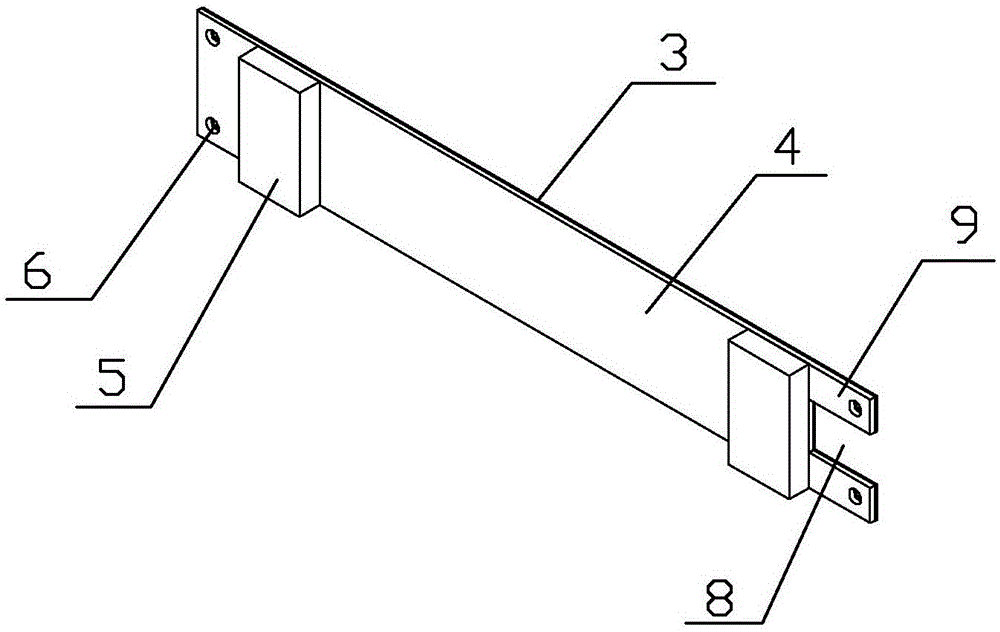

[0017] Embodiment: a kind of electric vehicle air conditioner silicone heating film heater of the present embodiment, such as figure 1 As shown, it includes a housing 1 and a plurality of silicone heating plate assemblies 2 installed in the housing 1. The housing is surrounded by four side plates to form a frame. There are no enclosures on the front and back of the housing. The silicone heating plate The component 2 is in the shape of a rectangular strip, and the silicone heating chip components are stacked in sequence and arranged at intervals from each other, and the electric wires connected to the silicone heating chip component 2 are connected in parallel. Such as figure 2 As shown, the silica gel heating sheet assembly 2 includes a strip-shaped heat-dissipating aluminum plate 3 and a strip-shaped silica gel heating film 4 pasted on the heat-dissipating aluminum plate 3. The block gap adjustment blocks 5 are respectively close to the two ends of the heat dissipation alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com