Polycarbonate/ABS composition, alloy, and preparation method thereof

A technology of polycarbonate and composition, applied in alloy and its preparation, polycarbonate/ABS composition field, can solve the problem that compatibilizer cannot balance impact performance and heat resistance, and achieve high impact performance and heat resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

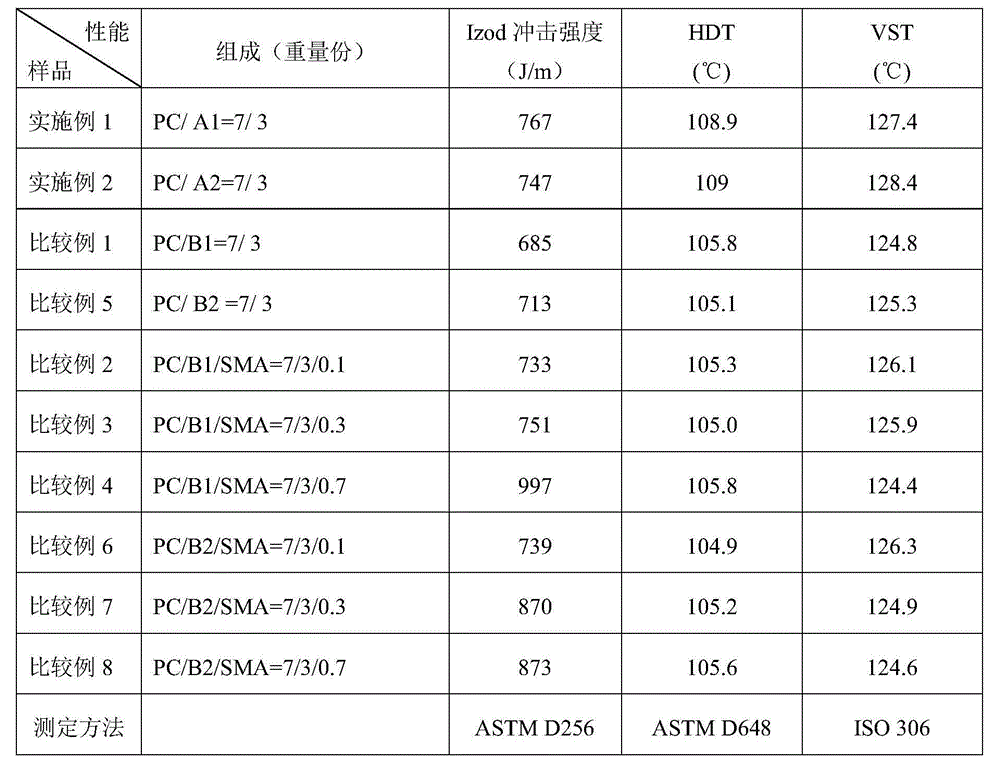

Examples

Embodiment 1

[0026] In this embodiment, the selected PC is produced by SABIC Company, with a molecular weight of 5×104g / mol, and ABS (A1) is produced by Sinopec Shanghai Gaoqiao Branch, wherein the N-phenylmaleimide content is 4%. The rubber content is 11%, and the volume average particle size is 1.1 μm. Antioxidant selected phenolic antioxidant 1010.

[0027] Pre-mix PC, A1, and antioxidant, and plasticize, knead, extrude, and pelletize the pre-mixed materials in a LeistrizAGMic-27 co-rotating twin-screw extruder made in Germany at a predetermined plasticizing temperature. The extrusion temperature is 210-300°C. Feed speed: 10kg / h, screw speed: 120rpm, residence time of the raw material in the extruder is 20 seconds. PC was vacuum dried at 120°C for 4 hours before blending and extrusion; A1 was vacuum dried at 80°C for 3 hours.

[0028] The method for measuring the Izod notched impact strength in the present invention is ASTM D256. Heat-resistant temperature measurement method one is ...

Embodiment 2

[0030] Prepare the PC / ABS alloy that improves impact and heat resistance by the step of embodiment 1, condition, test method, just change selected ABS for use. The ABS (A2) used in this example is produced by Sinopec Shanghai Gaoqiao Branch, with an N-phenylmaleimide content of 4%, a rubber content of 14%, and a volume average particle size of 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com