A preparation method of boron-containing steel for preventing slab corner cracking

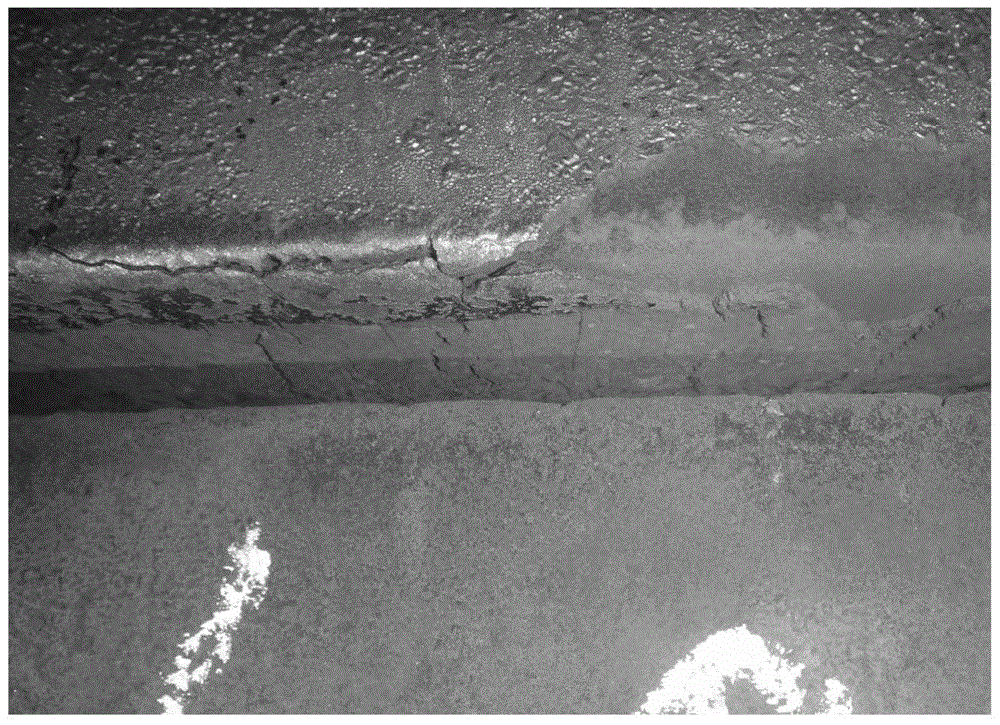

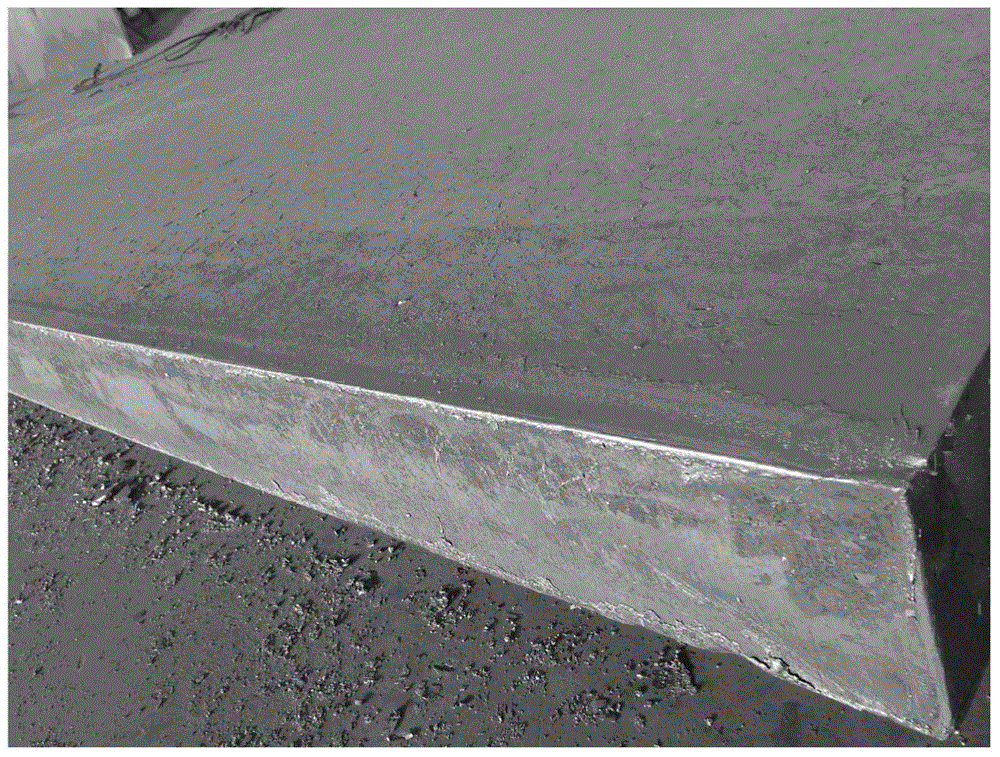

A boron steel and corner crack technology is applied in the field of preparing boron-containing steel for preventing corner cracking of cast billets, and can solve the problems such as easy cracks in the corners of boron-containing steel billets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

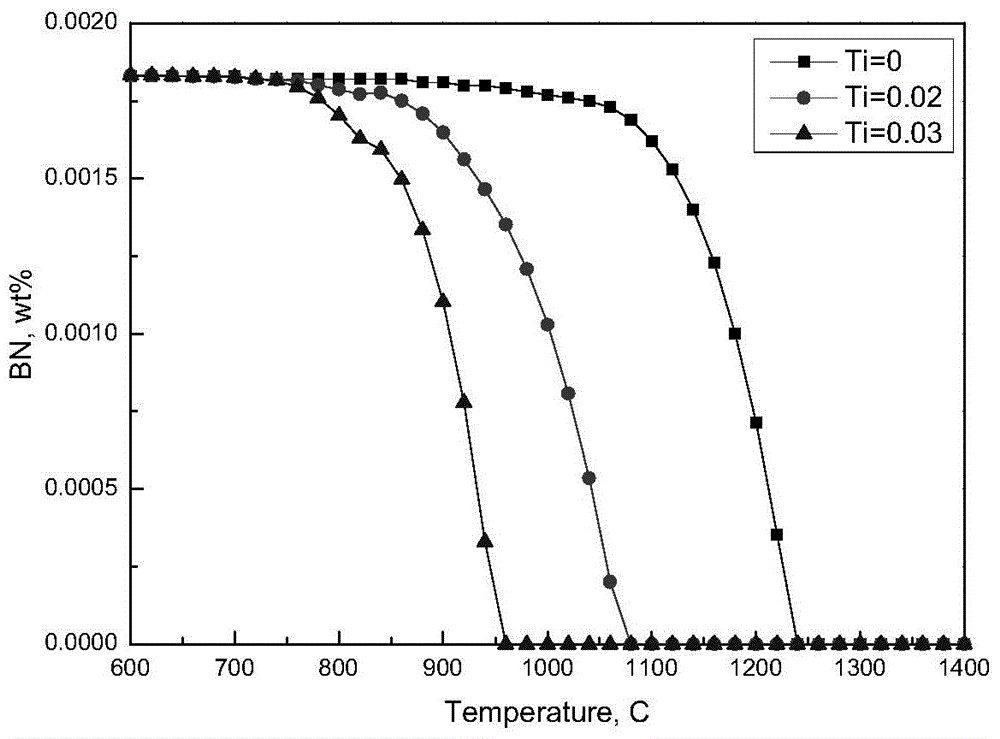

[0028] Example: SS400 steel

[0029] 1 According to the mass percentage of the chemical composition of boron steel, it contains: C0.17, Si0.12, Mn0.36, P0.009, S0.014, N0.0041, B0.0008; the balance is Fe.

[0030] 2 The process route is:

[0031] Hot metal pretreatment-converter smelting-external refining-ti addition-continuous casting-reheating-hot continuous rolling-inspection and storage.

[0032] 3 The main process measures of the preparation method

[0033] Steelmaking process: Traditional converter steelmaking is used for production. After tapping, argon gas is blown behind the furnace for 5 minutes, and the flow rate of argon gas is 0.4m 3 / min, argon blowing pressure 0.5MPa; starting from 1 / 4 of the tapping weight, start to add 350kg / 180 tons of aluminum and iron to the ladle for pre-deoxidation, add ferromanganese and ferrosilicon according to the content of Mn and Si in the final boron steel for alloying, and at the same time Add 500-600kg / 180 tons of active lime ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com