A flexible strain sensor based on ultralong tellurium microwires

A technology of strain sensor and micron wire, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of high cost and complicated device, and achieve the effect of low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

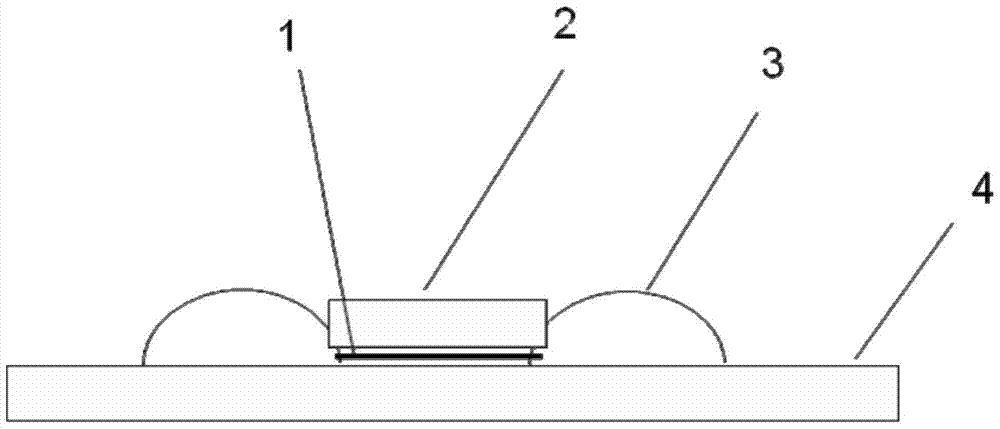

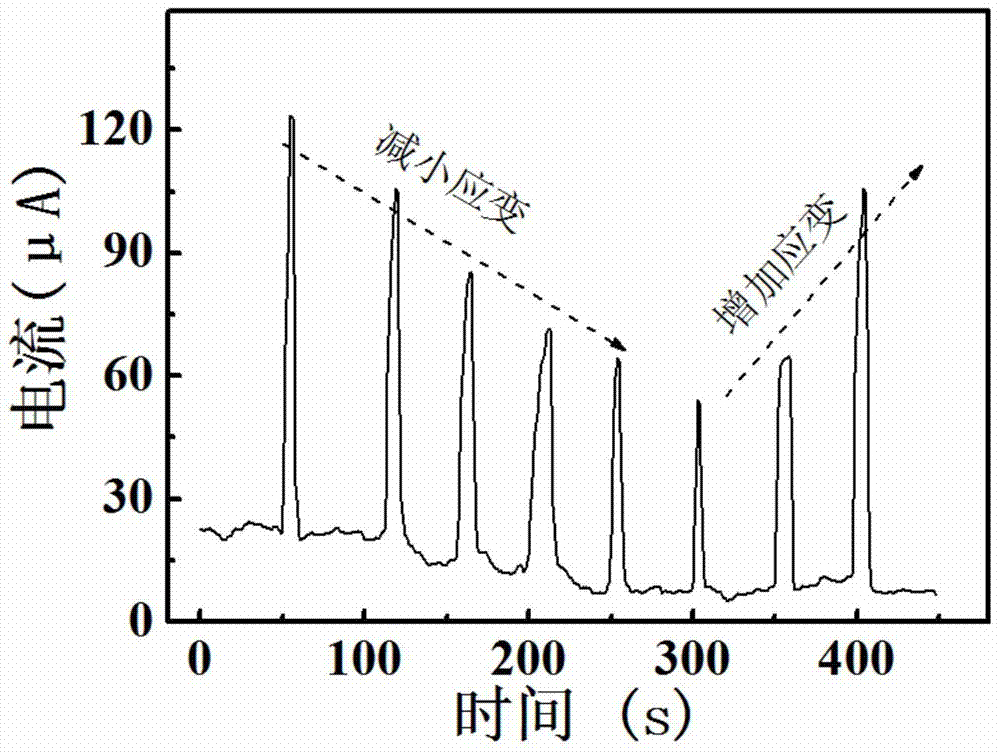

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] In the present invention, the ultra-long tellurium micron wire is prepared by a hydrothermal method. Step 1. dissolving 0.001mol of tellurium dioxide in 30ml of sodium hydroxide solution with a concentration of 1mol / L is placed in a beaker to obtain a mixed solution of A for subsequent use;

[0024] Step 2. Dissolve 0.15g of sodium borohydride in 30ml of sodium hydroxide solution with a concentration of 1mol / L, put it in a beaker, add 0.5g of dodecylsulfonic acid, and stir fully to obtain B mixed solution, which is set aside ;

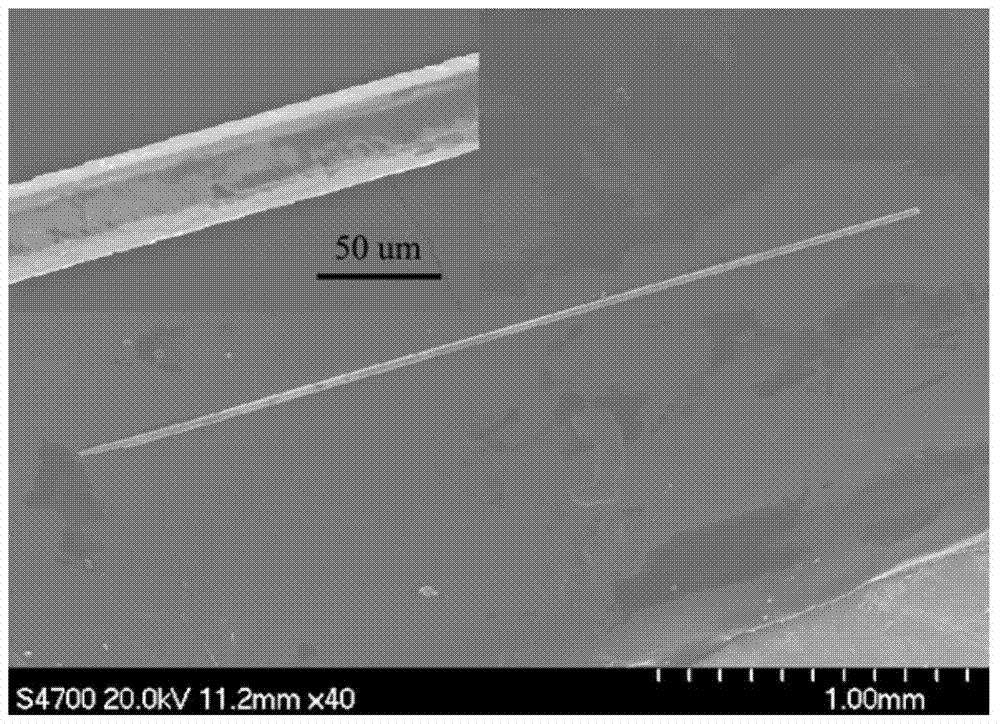

[0025] Step 3. Mix A mixture with B mixture, stir well, pour into 100ml polytetrafluoroethylene liner, add deionized water to dilute to 80ml, cover, put into stainless steel reaction kettle, at temperature React at 185°C for 24 hours. After the reaction, wash, filter, and dry to obtain tellurium microwires. att...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com