Intelligent laser residual glue removing system and method for coating surface at aircraft covering cap

A technology of residual glue and coating, which is applied in the field of intelligent laser residual glue removal system on the coating surface of the aircraft cover, can solve the problems that cannot meet the requirements of aircraft coating surface residual glue removal, etc., to achieve expansion adaptability and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

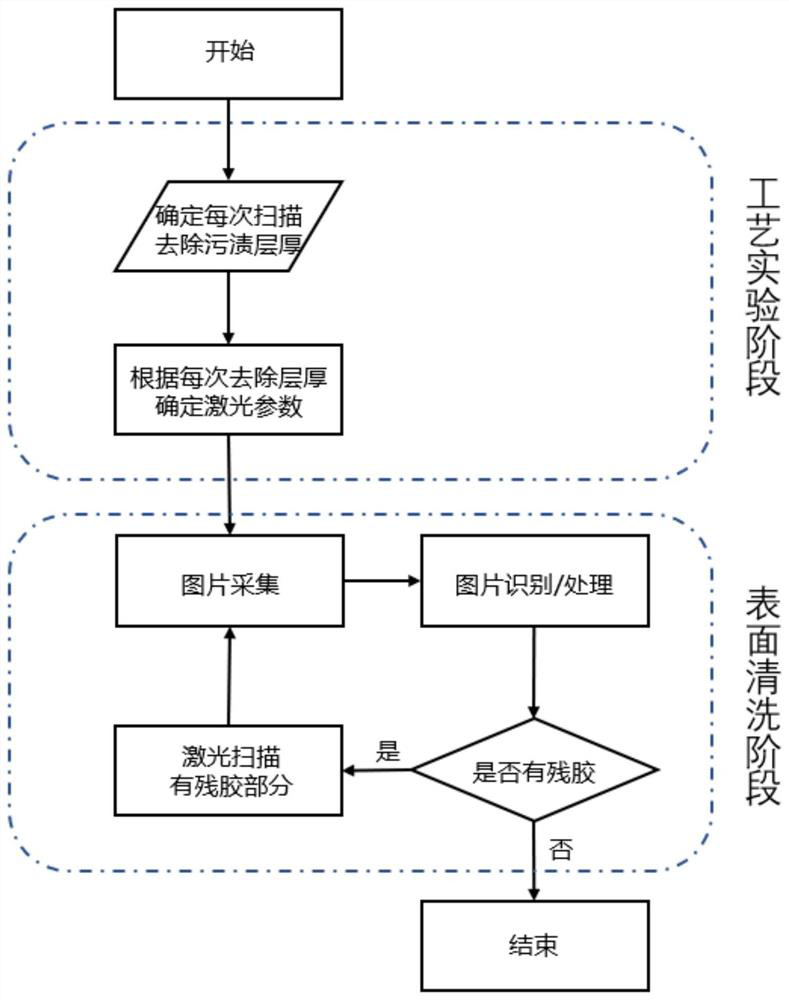

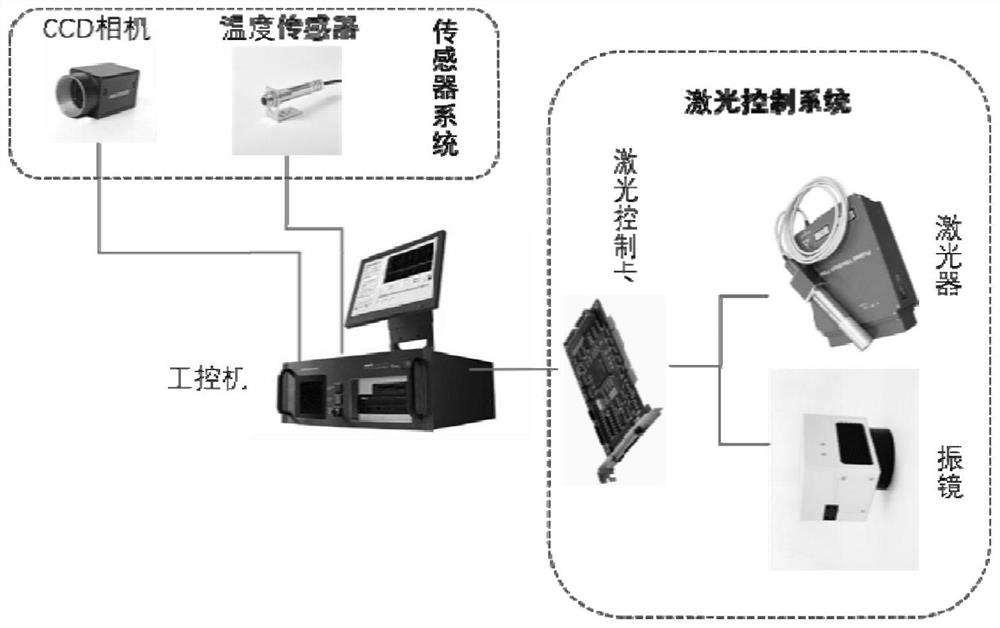

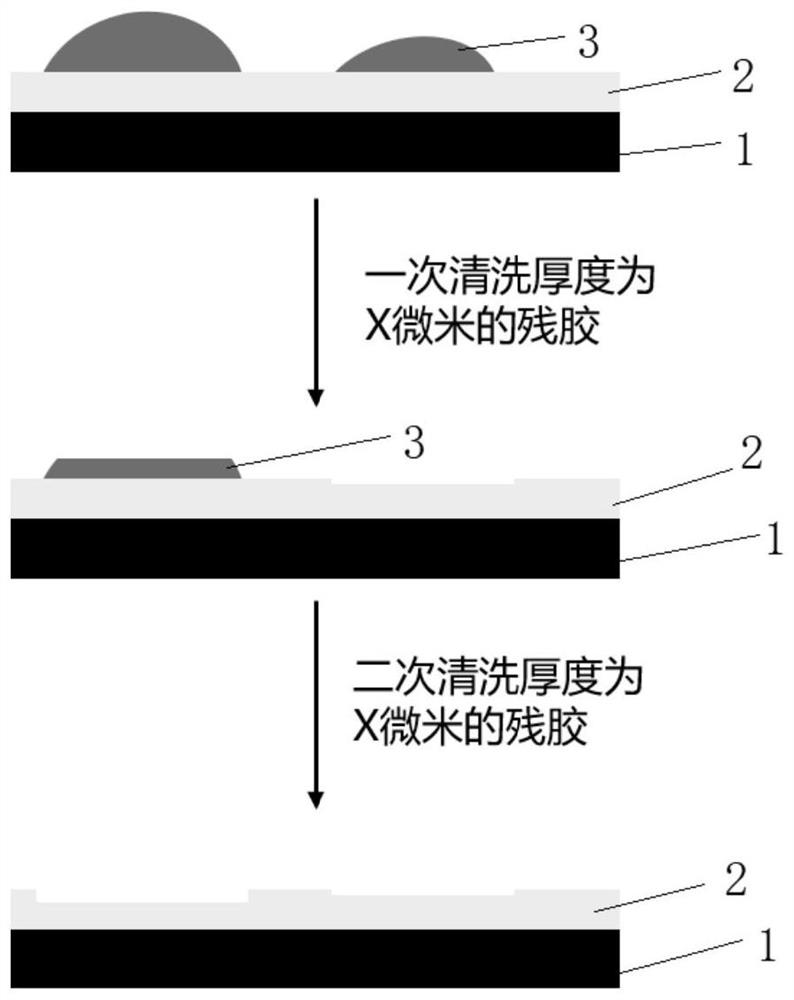

[0033] The present invention is an intelligent laser residue removal system on the coating surface of the aircraft flap, including medium and high power lasers (above 50W, multi-mode, wavelength ultraviolet, visible light and infrared), industrial cameras, temperature sensors, 2D / 3D vibrating mirrors, Industrial computer and supporting control software, if attached figure 2 shown. In order to meet the process requirements, the entire intelligent system is controlled by software. The movement of the galvanometer and the light output parameters of the laser are controlled by corresponding software and a matching laser control card. The data collection and analysis of industrial cameras and temperature sensors are all done by computers. The basic technical route of the intelligent laser cleaning system is: use the industrial comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com