Protective coating for repairing metal surface damage, preparation method and composite material

A protective coating and metal surface technology, applied in anti-corrosion coatings, coatings, polyester coatings, etc., can solve problems such as potential safety hazards, corrosion damage of steel pipe piles, and reduced service life, and achieve high anti-erosion and wear effects , Repair damage, improve the effect of interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

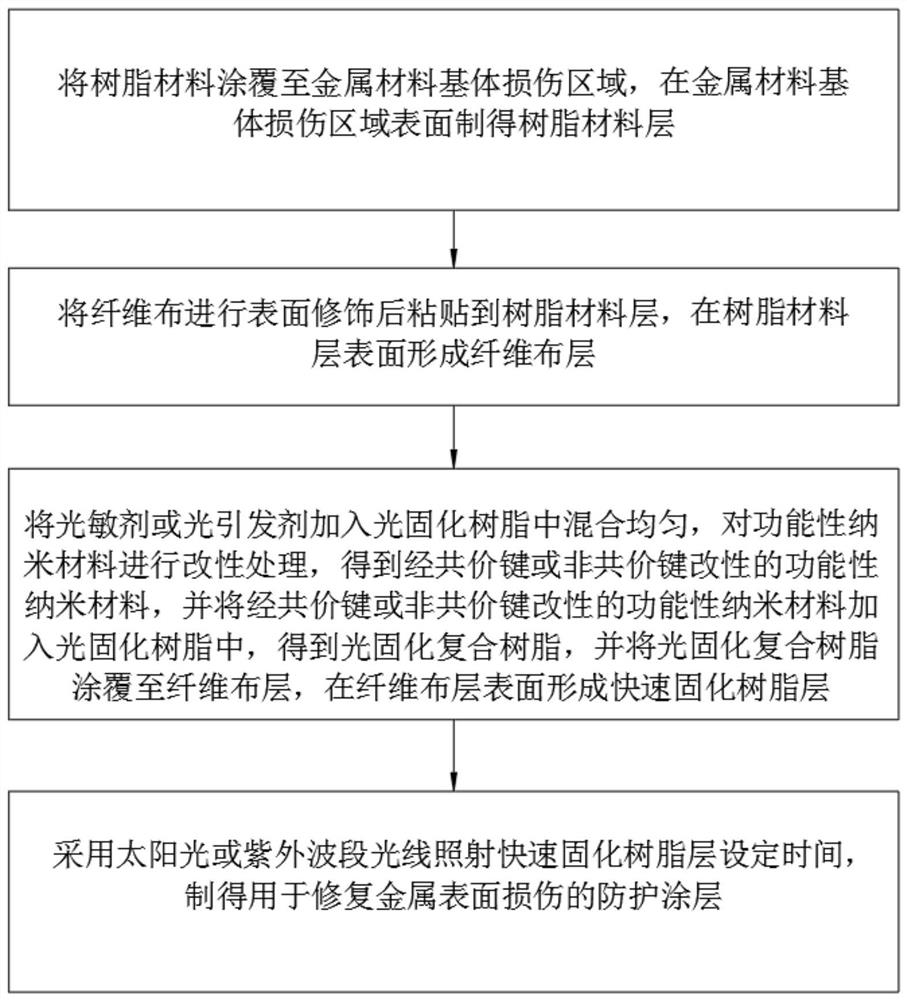

[0035] like figure 1As shown, another embodiment of the present invention provides a method for preparing the above protective coating, comprising the steps of:

[0036] Coating the resin material to the damaged area of the metal material base, and preparing a resin material layer on the surface of the damaged area of the metal material base;

[0037] After surface modification, the fiber cloth is pasted to the resin material layer, and a fiber cloth layer is formed on the surface of the resin material layer;

[0038] The photosensitizer or photoinitiator is added to the photocurable resin and mixed evenly, and the functional nanomaterials are modified to obtain functional nanomaterials modified by covalent bonds or non-covalent bonds. The functional nanomaterials modified by non-covalent bonds are added to the photocurable resin to obtain the photocurable composite resin, and the photocurable composite resin is applied to the fiber cloth layer to form a fast curing resin...

Embodiment 1

[0048] The cationic photo-initiating material is added to the epoxy acrylate and mixed evenly, wherein the content of the photo-initiating material is 5wt%;

[0049] The ultra-high molecular weight polyethylene nanomaterials were modified by covalent bonds with chitosan, and the covalently modified ultra-high molecular weight polyethylene nanomaterials with a mass fraction of 1 wt% were added to epoxy acrylate to obtain epoxy resins. Acrylic composite resin coating;

[0050] Coating epoxy resin on the surface of the corrosion damaged steel pipe pile, and pasting the surface-modified plain ultra-high molecular weight polyphenylene sulfide fiber cloth on the epoxy resin;

[0051] The epoxy acrylic composite resin coating is coated on the surface of ultra-high molecular weight polyphenylene sulfide fiber cloth to form such as figure 2 Fast curing fiber cloth reinforced coating shown;

[0052] At room temperature, the fast-curing fiber cloth reinforced coating is completely cur...

Embodiment 2

[0057] The photosensitizer is added to the urethane acrylate and mixed evenly, wherein the content of the photosensitizer is 8wt%, and 1wt% of the boron nitride nanomaterial modified by the covalent bond of nanocellulose is added to the urethane acrylate to obtain the polyurethane Acrylate composite resin coating;

[0058] Paste the twill aramid fiber cloth to the surface of the corrosion-damaged steel pipe pile coated with epoxy resin;

[0059] The polyurethane acrylate composite resin coating is coated on the surface of the twill aramid fiber cloth to form a fiber cloth composite material;

[0060] At room temperature, the fast-curing fiber cloth reinforced coating is completely cured to form a hard fiber cloth coating after being irradiated with ultraviolet light in the 365 nm band for 2 minutes.

[0061] In this embodiment, the fiber cloth coating has a high impedance modulus, and its low-frequency impedance value can reach 8×10 11 Ω / cm 2 , and has excellent erosion res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com