Onboard Fuel System Remote Interface Unit

A fuel system and remote interface technology, which is applied in the field of remote interface unit RIU, can solve the problem of complex signal distribution, improve fault detection and fault tolerance, reduce equipment weight, and reduce connection complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

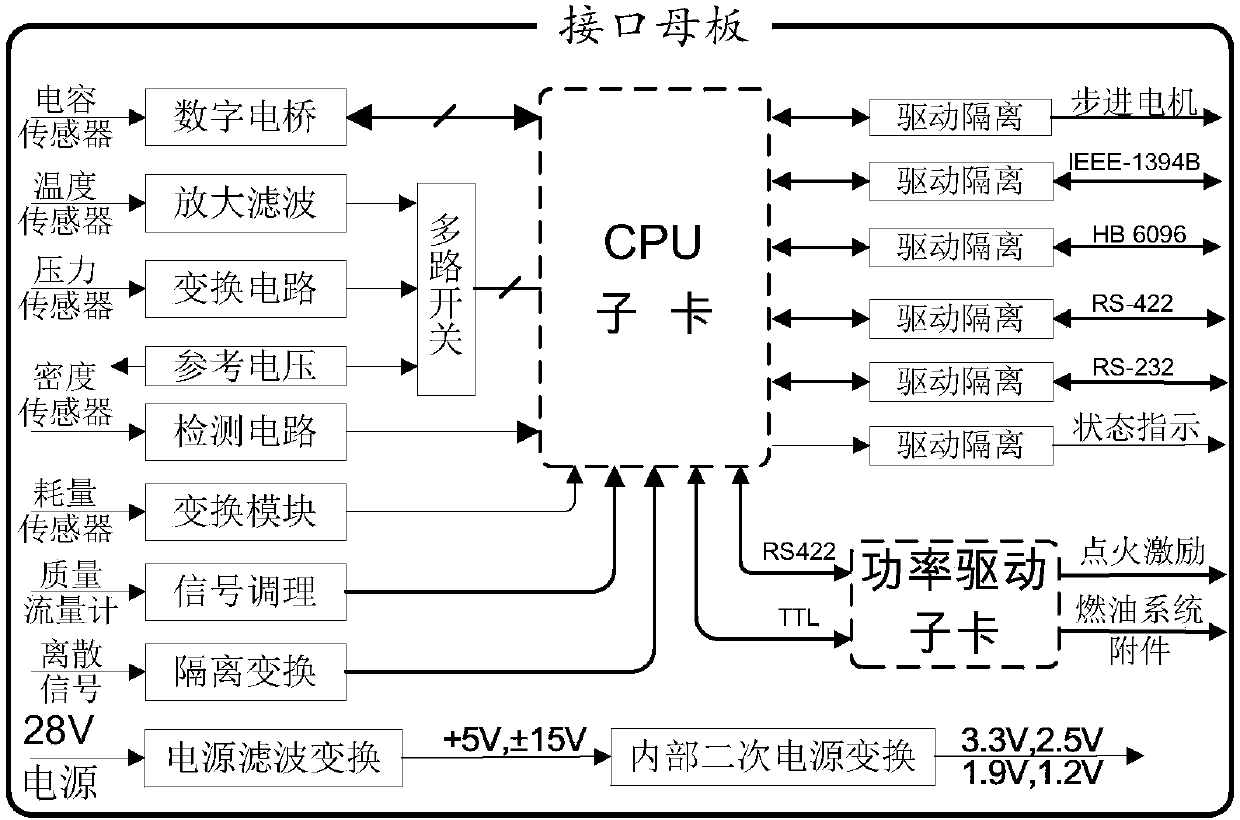

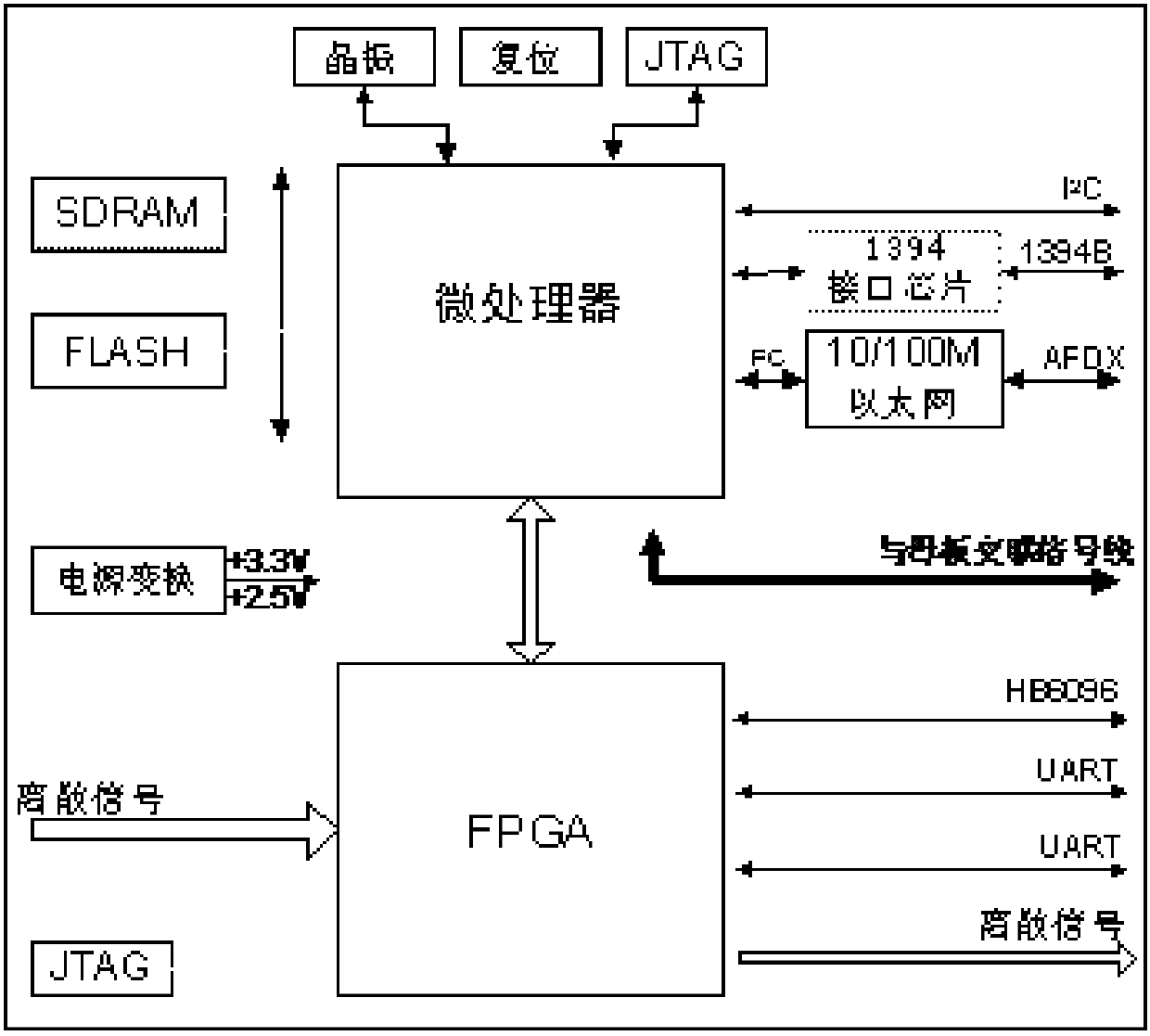

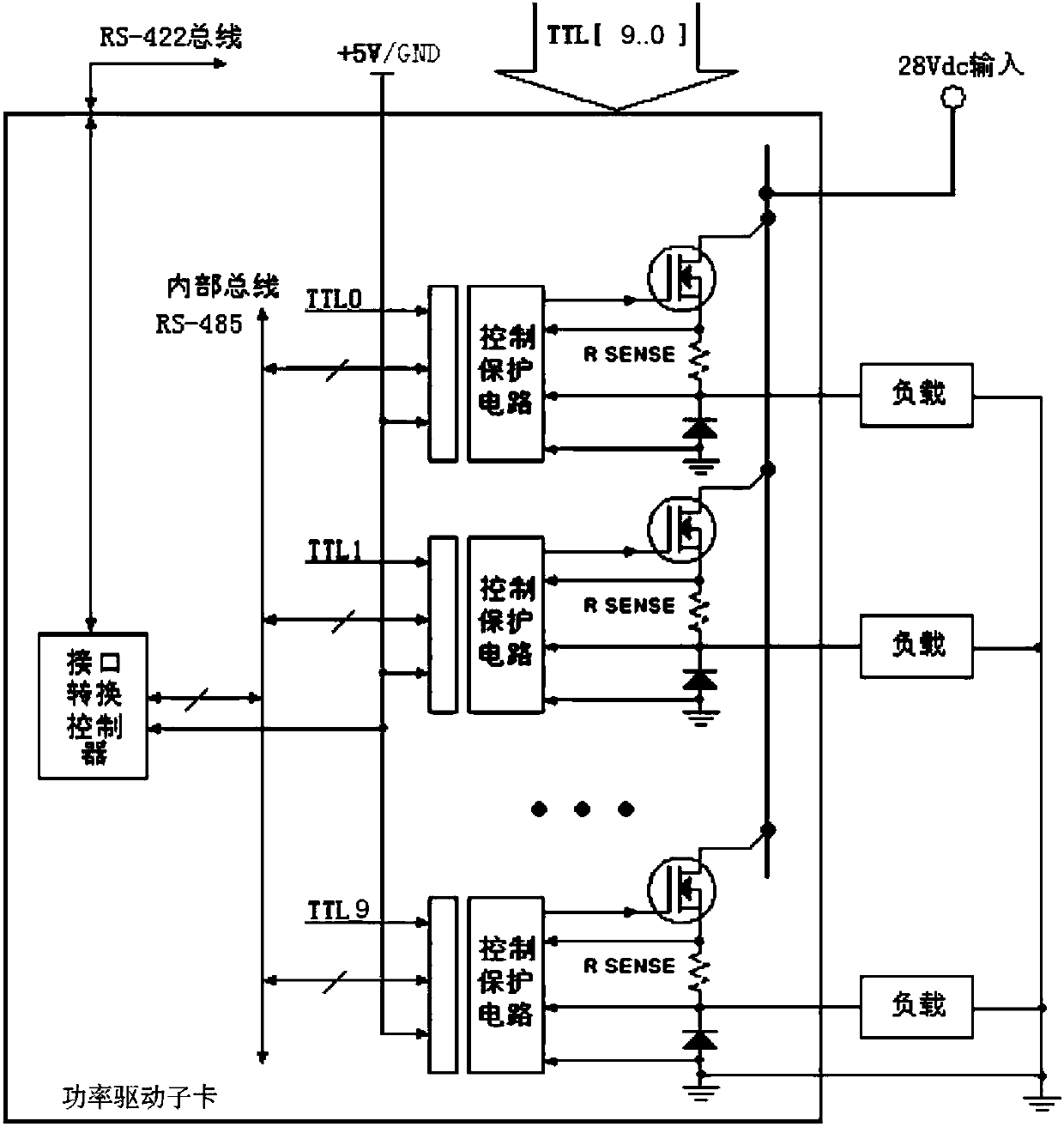

[0021] refer to figure 1 . In one embodiment described below, the remote interface unit is a signal processing terminal of the fuel system. Various control signals and sensor signals of the fuel system are connected to the airborne, vehicle or shipboard bus network through the RIU, and uploaded to the management computer UMC, so that the UMC can communicate with the fuel system. The remote interface unit of the on-board fuel system is set in the flat square structure case. The remote interface unit of the airborne fuel system mainly includes: a CPU sub-card electrically connected to the interface motherboard, a power drive sub-card, and various interfaces for collecting, processing and outputting signals from various sensors in the fuel tank. Among the various interfaces, the temperature sensor conversion interface is connected to the CPU sub-card through the sliding filter circuit, the pressure sensor conversion interface is connected to the CPU sub-card through the multi-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com