Rare earth ion doped GdCl3 microcrystalline glass and preparation method thereof

A technology of glass-ceramics and rare earth ions, which is applied in the field of rare-earth ion-doped GdCl3 glass-ceramics and its preparation, can solve the problems of affecting the up-conversion luminescence output and poor physical and chemical properties of sulfide, and achieve excellent up-conversion performance and mechanical properties. The effect of good performance and low phonon energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

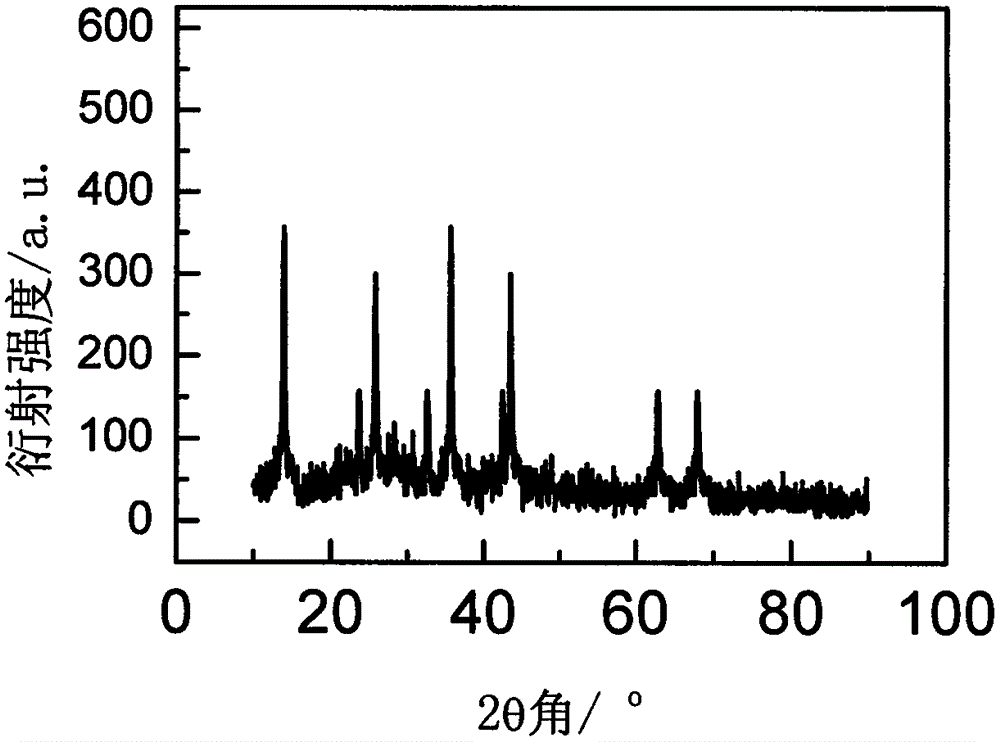

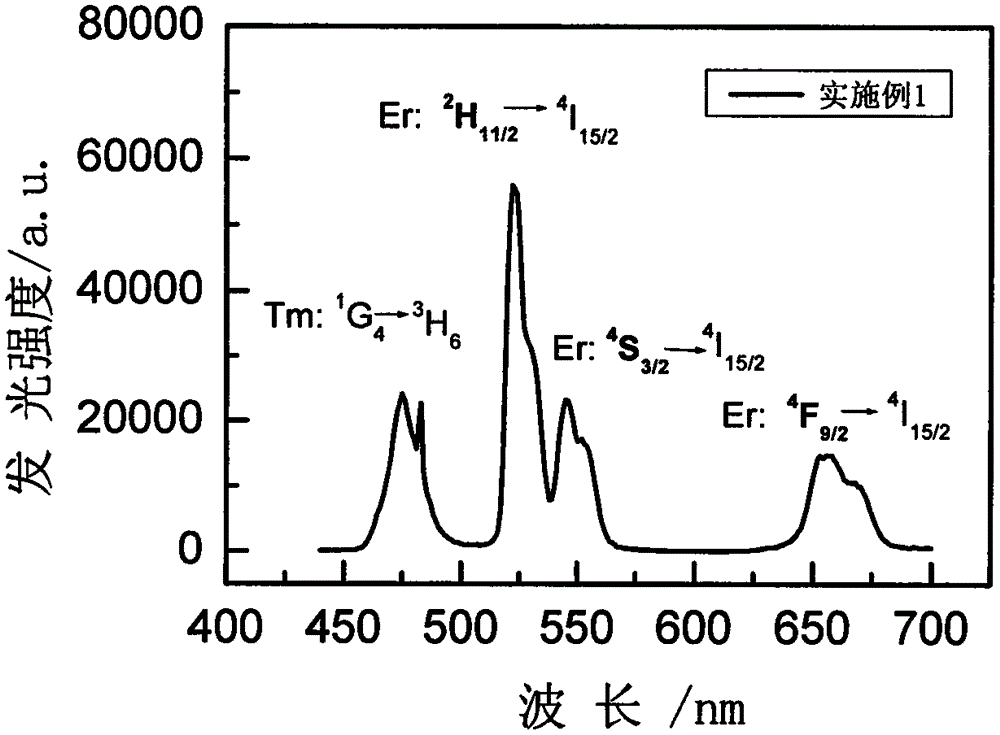

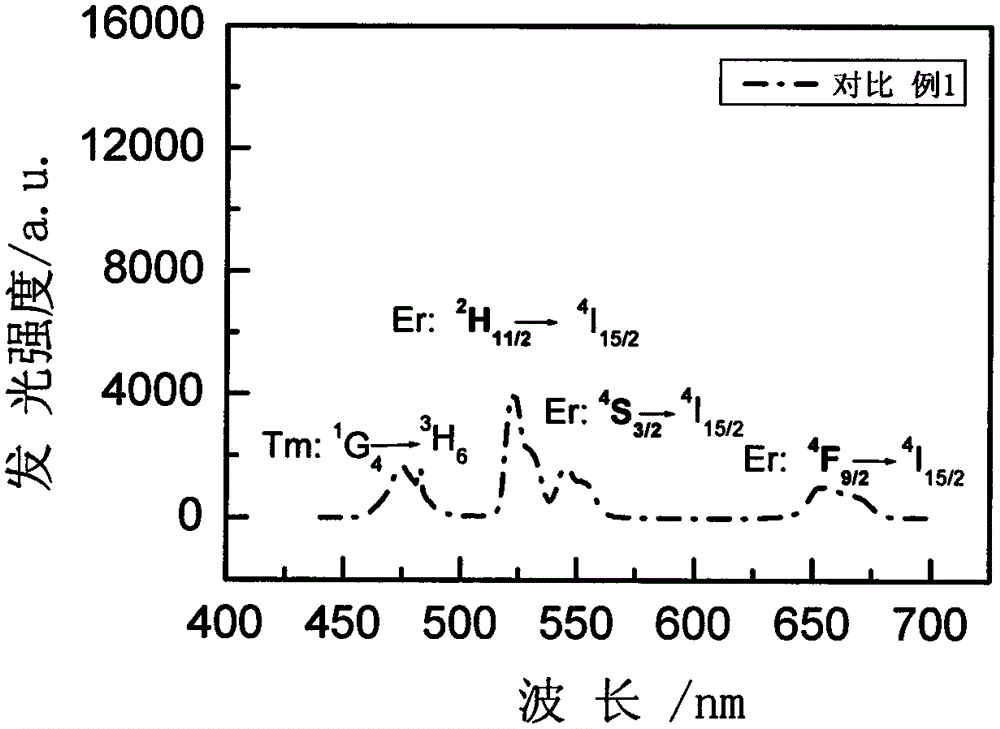

[0020] Er 3+ 、Tm 3+ , Yb 3+ doped GdCl 3 The molar percentage composition of glass ceramics is: SiO 2 80mol%, GdCl 3 16mol%, ErCl 3 0.1mol%, TmCl 3 0.1mol%, YbCl 3 3.8mol%, the process for preparing glass-ceramics of the above composition is as follows:

[0021] (1) Weigh gadolinium acetate, ytterbium acetate, erbium acetate and thulium acetate, and the parts are GdCl in the above mole percentage composition 3 , YbCl 3 , ErCl 3 and TmCl 3 Weigh the molar percentage content, dissolve the above-mentioned acetate in deionized water to form an acetate solution, add trichloroacetic acid to the acetate solution to obtain a transparent mixed solution, wherein trichloroacetic acid and acetate solution The molar ratio of the sum of metal ions is 3:1;

[0022] (2) SiO in the same molar percentage composition as step (1) 2 The molar percentage content takes ethyl orthosilicate and dissolves it in ethanol to obtain ethyl orthosilicate solution, then mixes the mixed solution p...

Embodiment 2

[0027] T m 3+ , Yb 3+ doped GdCl 3 The molar percentage composition of glass ceramics is: SiO 2 80.5mol%, GdCl 3 15mol%, TmCl 3 0.5mol%, YbCl 3 4mol%, after the same preparation and heat treatment process as in Example 1, a transparent rare earth ion Tm 3+ , Yb 3+ Doped GdCl 3 Glass-ceramic. The glass-ceramic was measured with a TRIAX550 fluorescence spectrometer, under the excitation condition of a 970nm laser, a strong blue up-conversion luminescence was observed.

Embodiment 3

[0029] Er 3+ , Yb 3+ doped GdCl 3 The molar percentage composition of glass ceramics is: SiO 2 81.5mol%, GdCl 3 14mol%, ErCl 3 0.5mol%, YbCl 3 4mol%, after the preparation and heat treatment process identical with embodiment 1, obtain transparent rare earth ion Er 3+ , Yb 3+ Doped GdCl 3 Glass-ceramic. The spectral properties of the glass-ceramic were tested, and the up-conversion luminescence spectrum under the excitation condition of 970nm laser was measured by TRIAX550 fluorescence spectrometer, and strong green and red up-conversion luminescence were observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com