Novel butyl rubber and preparation method thereof

A technology of butyl rubber and chlorinated butyl rubber, which is applied in the field of rubber compositions, can solve the problems of slow vulcanization speed, poor self-adhesiveness and mutual adhesion, and poor compatibility of butene rubber, and achieve increased strength and gloss, Good dispersibility and prolong shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

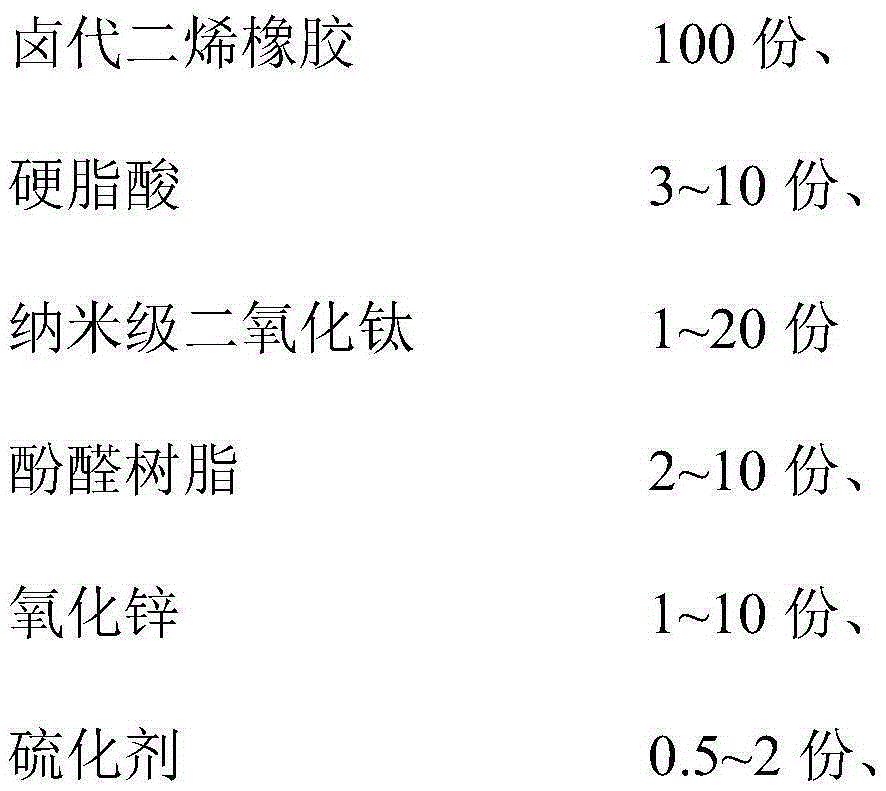

[0026] A novel butyl rubber comprising the following components in parts by mass:

[0027]

[0028] Among them, the halogenated diene rubber is 55 parts by mass of brominated butyl rubber and 45 parts by mass of chlorinated butyl rubber, and the average particle diameter of nanoscale titanium dioxide, nanoscale silver powder and nanoscale montmorillonite powder is 100nm. The agent is mica treated with silane coupling agent, and the vulcanizing agent is sulfur.

Embodiment 2

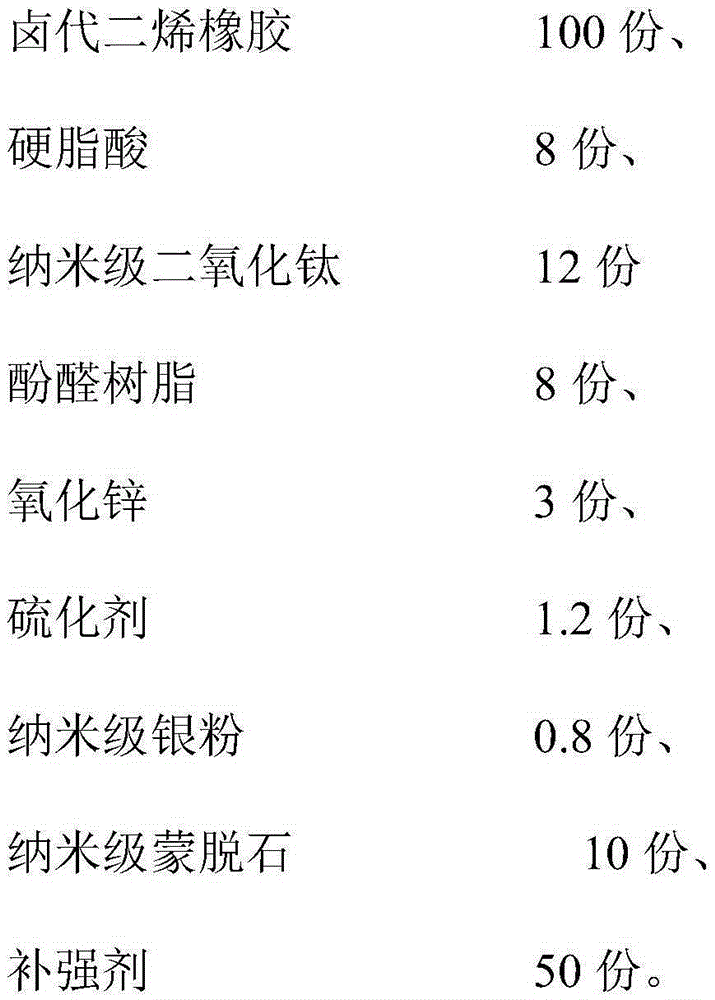

[0030] A novel butyl rubber comprising the following components in parts by mass:

[0031]

[0032] Among them, the halogenated diene rubber is 70 parts by mass of brominated butyl rubber and 30 parts by mass of chlorinated butyl rubber, and the average particle diameter of nanoscale titanium dioxide, nanoscale silver powder and nanoscale montmorillonite powder is 50nm, reinforcing The agent is a mixture of silica and mica treated with a silane coupling agent, and the vulcanizing agent is sulfur.

Embodiment 3

[0034] A novel butyl rubber comprising the following components in parts by mass:

[0035]

[0036]

[0037] Among them, the halogenated diene rubber is 35 parts by mass of brominated butyl rubber and 65 parts by mass of chlorinated butyl rubber, and the average particle diameter of nanoscale titanium dioxide, nanoscale silver powder and nanoscale montmorillonite powder is 200nm, and the reinforcement The agent is a mixture of modified clay and kaolin treated with a silane coupling agent, and the vulcanizing agent is sulfur.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com