Palladium electroplating solution containing sodium nitrite and tetraphenylarsonium bromide and electroplating method thereof

A technology of tetraphenyl arsenium bromide and sodium nitrite, applied in the field of palladium electroplating solution, can solve the problems of decreased wire adhesion and solder wettability, difficult to control the thickness of palladium coating, difficult to obtain ductility, etc. The effect of good coating quality, excellent bath performance and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

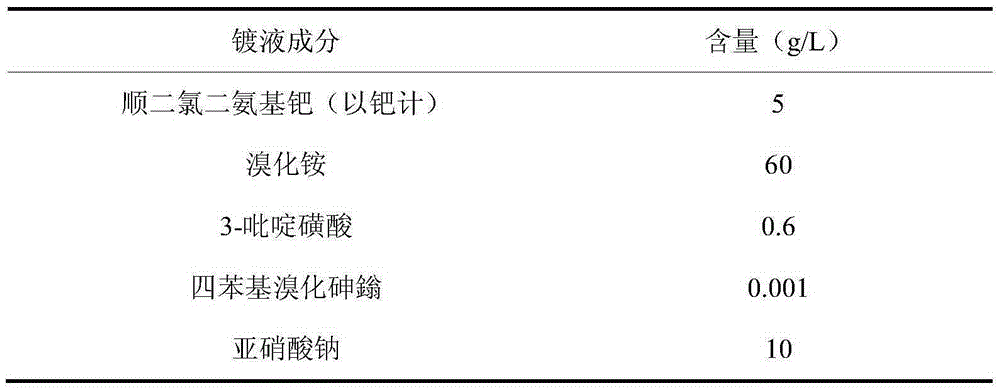

[0029] The formulation of the electroplating solution is as follows:

[0030]

[0031] Plating process conditions: the pulse width of the single pulse square wave current is 2ms, the duty cycle is 30%, and the average current density is 2A / dm 2 ; The pH is 7.5, the temperature is 45°C, and the electroplating time is 9 minutes.

Embodiment 2

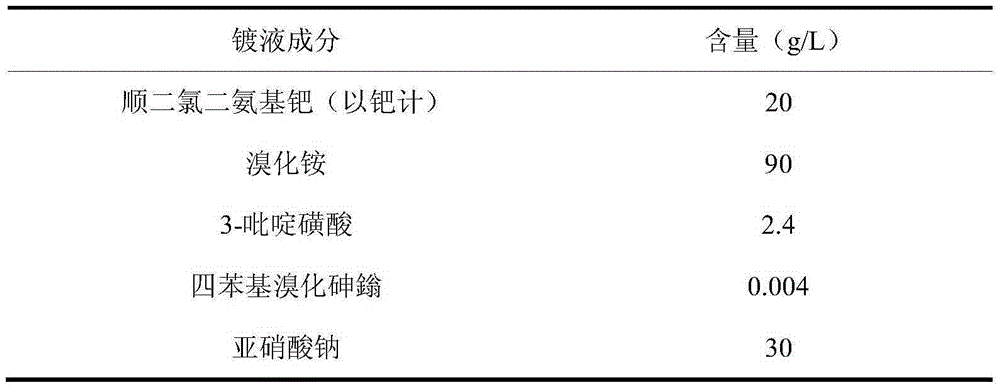

[0033] The formulation of the electroplating solution is as follows:

[0034]

[0035] Plating process conditions: the pulse width of single pulse square wave current is 0.6ms, the duty cycle is 25%, and the average current density is 2.5A / dm 2 ; The pH is 7.5, the temperature is 45°C, and the electroplating time is 5min.

Embodiment 3

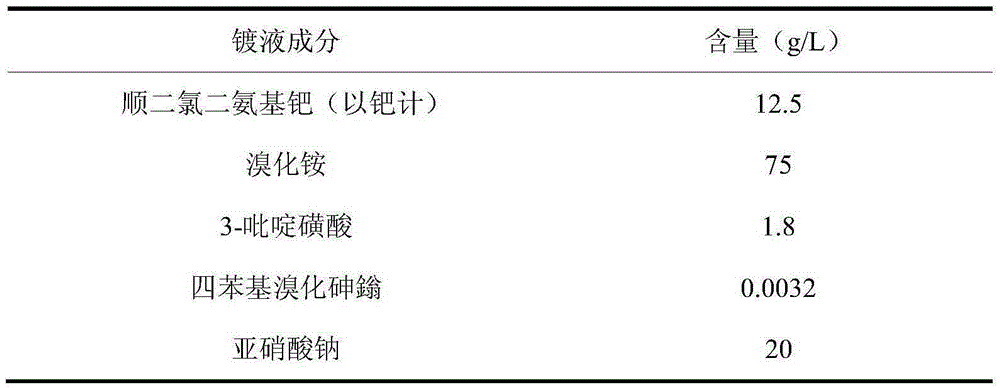

[0037] The formulation of the electroplating solution is as follows:

[0038]

[0039] Plating process conditions: the pulse width of single pulse square wave current is 0.8ms, the duty cycle is 20%, and the average current density is 3A / dm 2 ; The pH is 8.5, the temperature is 55°C, and the electroplating time is 6 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com