Total hydrocarbon tester having on-line attenuation function

A measuring instrument and functional technology, applied in the field of total hydrocarbon measuring instrument, can solve the problems of inaccurate dilution ratio, difficult discovery, difficult adjustment of gas path resistance, etc., to avoid flameout of the detector, improve efficiency, and avoid filter material penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

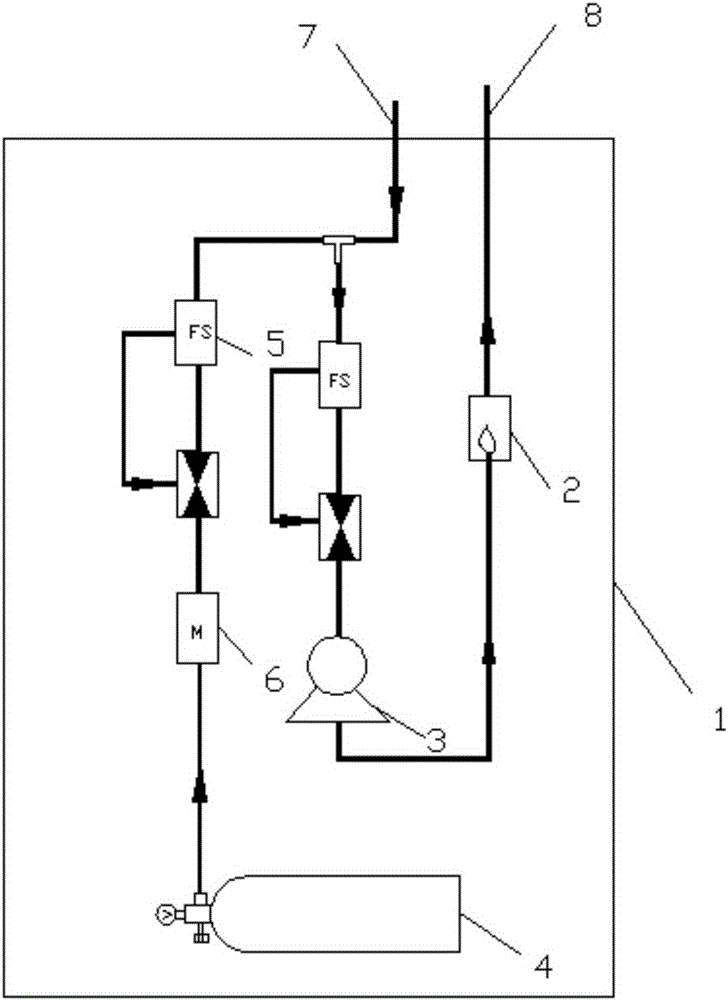

[0018] combined with figure 1 The specific embodiment of the present invention is described further:

[0019] A total hydrocarbon analyzer 1 with an online dilution function includes a sampling tube 7, a pump 3, a hydrogen flame ion detector 2, and a compressed air bottle 4 and a mixed gas chamber. The mixed air chamber has two input ends, one input end is connected with the sampling pipe, the other input end is connected with the air pipe, the air pipe is connected with the compressed air bottle, and the air flow control device 5 is also arranged on the air pipe. The output end of the mixed gas chamber is connected to the pump through the mixed gas flow control device, and the pump is connected to the hydrogen flame ion detector.

[0020] The sampling pipe inputs the sample gas into the mixed gas chamber, and the clean air from the compressed air bottle enters the mixed gas chamber through the air flow control device to mix with the sample gas. The air flow control device co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com