Packaging technology of highly-reliable surface mounting glass-packaged diode

A glass-encapsulated diode, surface mount technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of low reliability, can not meet long-term reliability and other problems, achieve high reliability, light weight, low thermal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described and defined below in conjunction with the accompanying drawings and specific embodiments.

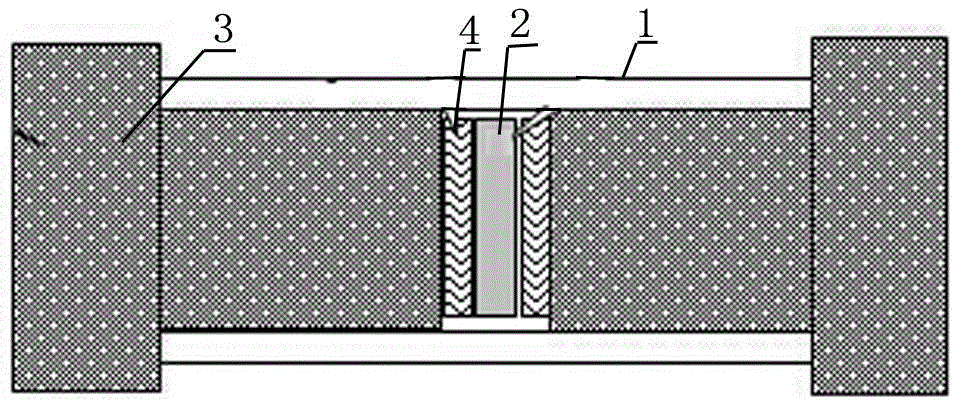

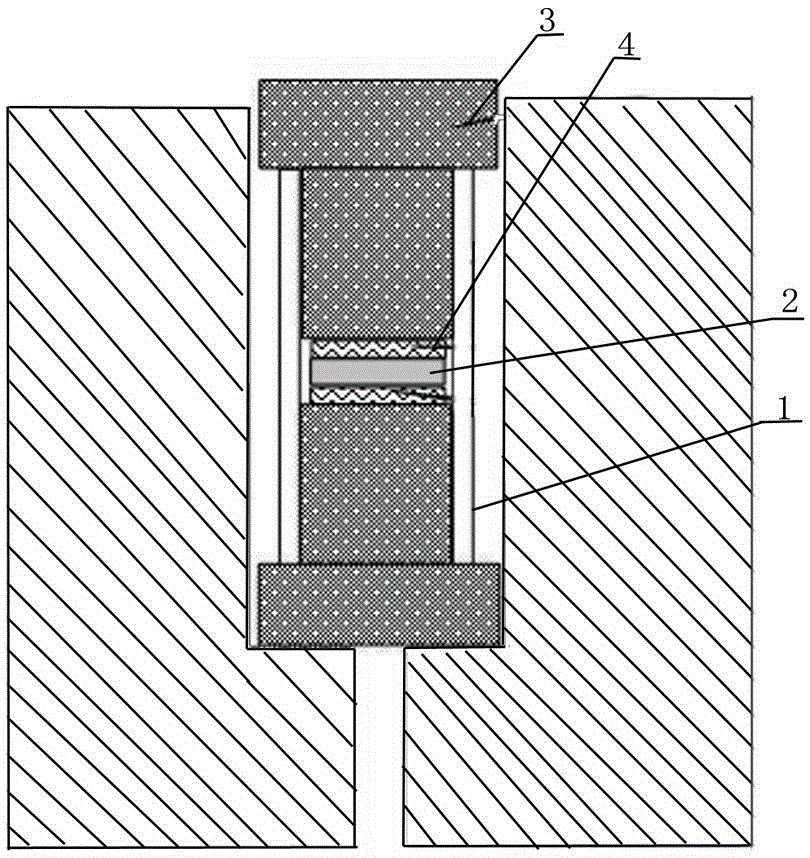

[0020] Such as figure 1 As shown, it is a schematic diagram of the structure of the surface-mounted glass-encapsulated diode described in this embodiment, including a glass bulb 1, a chip 2 located in the middle of the glass bulb 1, a terminal 3 sleeved at both ends of the glass bulb 1, and a terminal 3 located at the terminal 3. The solder tab 4 between the chip 2 and the chip 2, in this embodiment, the glass bulb 1 and the terminal 3, the glass bulb 1 and the solder tab 4, and the chip 2 are bonded together through a pyrometallurgical bonding process.

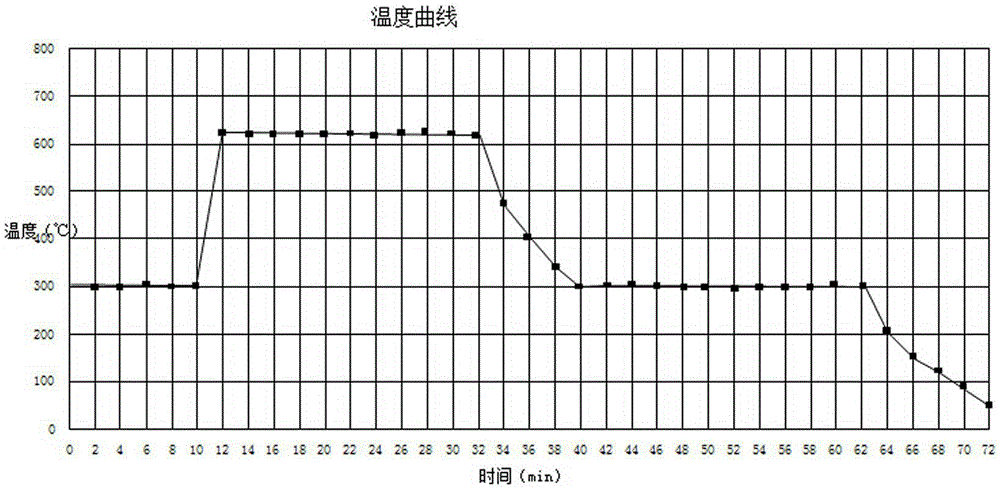

[0021] In this implementation, the packaging process of the high-reliability surface-mounted glass-encapsulated diode includes the following steps:

[0022] 1) Prepare a chip with a chip thickness of 210μm±50μm;

[0023] 2), use the mold to assemble the chip, solder piece, termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com