Apparatus for flue gas desulfurization and denitrification

A flue gas and denitrification technology, used in climate change adaptation, climate sustainability, and use of liquid separators, etc. long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

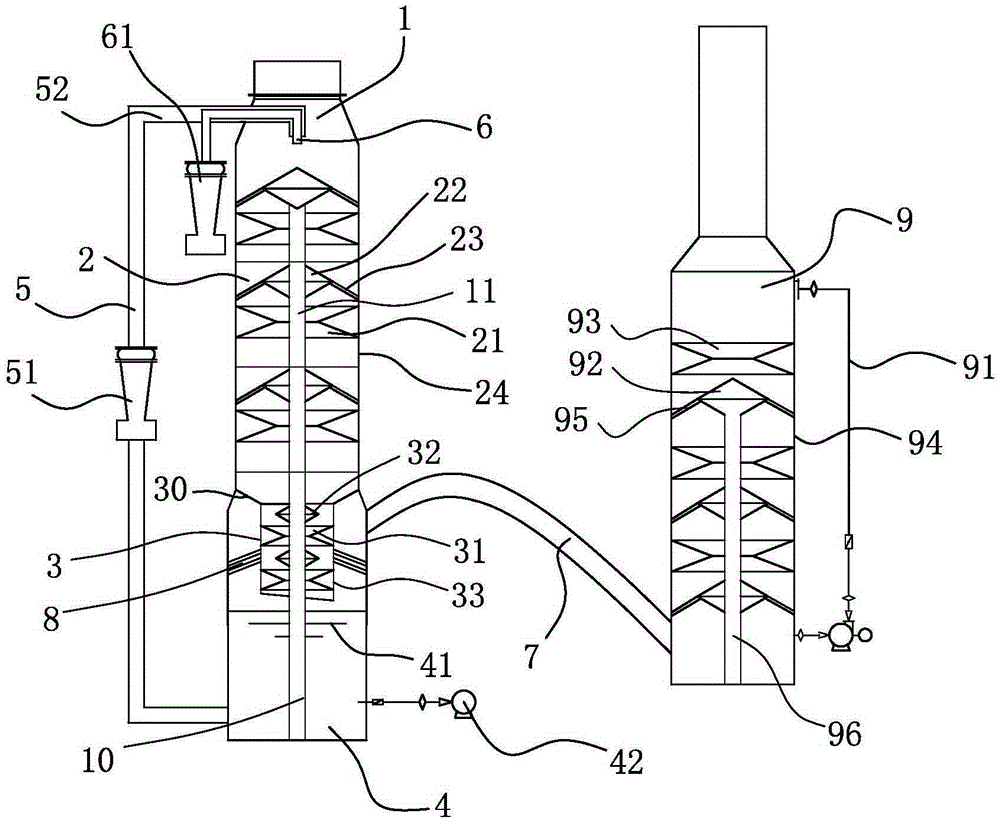

[0018] Combine below figure 1 A detailed description will be made to the specific embodiment of the present invention.

[0019] Such as figure 1 The shown equipment for flue gas desulfurization and denitrification includes a first multiphase reactor system 1, a water circulation system 5, a slurry tank 4, a slurry discharge device 42, an outlet pipe 7, and a second multiphase reactor System 9 and water shower 91.

[0020] The top of the first multiphase reactor system 1 is the flue gas inlet, the first multiphase reactor system 1 is above the slurry pool 4 , and the slurry discharge device 42 is connected to the slurry pool 4 . A slurry 41 is provided in the slurry tank 4, and the slurry 41 is made by mixing one or more of ironmaking slag, steelmaking slag, fly ash, and iron scale with water, and the concentration of the slurry 41 is 5%-20% between.

[0021] The slurry pool 4 communicates with the second multiphase reactor system 9 through the gas outlet pipe 7 , and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com