Symmetric built-in anaerobic membrane bioreactor

An anaerobic membrane biology, built-in technology, applied in anaerobic digestion treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of serious membrane pollution, uneven mass transfer, unstable effluent, etc., to achieve The reaction rate is fast, the separation efficiency is improved, and the effect of delaying membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

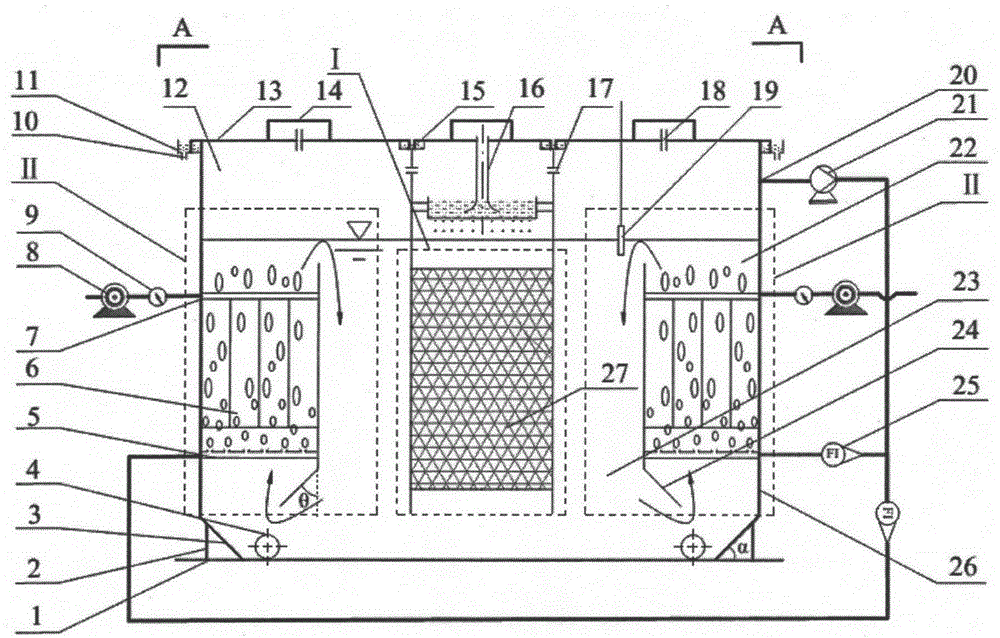

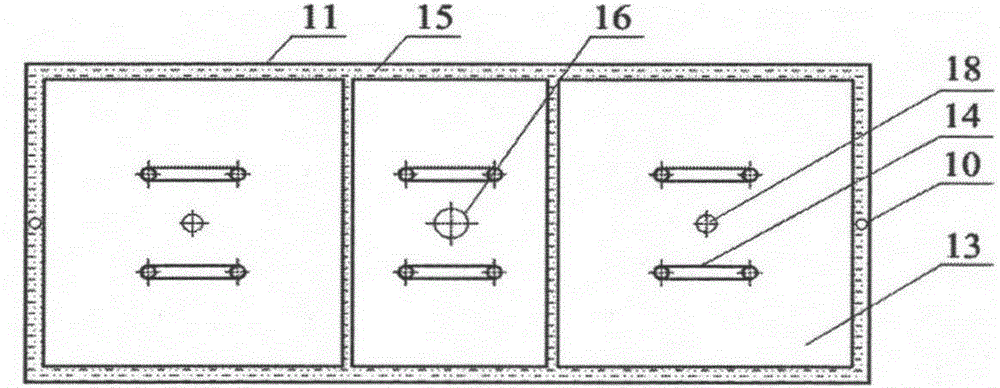

[0042] Such as figure 1 As shown, the symmetric built-in anaerobic membrane bioreactor of the present invention includes a shell, and the inside of the shell is divided into a packing area I and a membrane area II by a partition, and the packing area I and the film area II are respectively used to realize the hydrolysis acidification stage and hydrogen-producing methane stage. The membrane zone II is symmetrically arranged on both sides of the filler zone I.

[0043] Filler 27 is provided in the filler area I, and a sieve feed water distributor 16 is arranged above the filler 27. Waste water flows through the filler 27 and enters the membrane area II. A baffle plate 24 is provided in the membrane area II. The upper part of the baffle plate 24 is placed vertically, and the included angle θ between the lower part and the vertical direction is 60°. The baffle plate 24 divides the membrane zone II into a circulation zone 23 and a mud-water separation zone 22, the circulation zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com