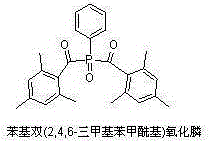

Preparation method for phenyl bis(2,4,6-trimethylbenzoyl)phosphine oxide

A technology of trimethylbenzoyl and phenylbis, which is applied in the field of preparation of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide (819), can solve the problem of phenylbis(2) , 4,6-trimethylbenzoyl) technical scheme disclosure of phosphine oxide and other problems, to achieve the effects of environmental friendliness, low cost and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

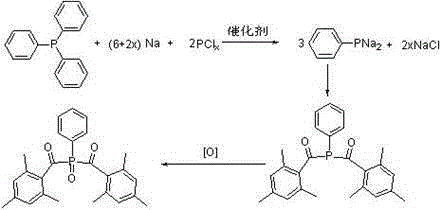

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of embodiment 1 phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide

[0033] 1) Under the protection of nitrogen, suspend metal sodium block (13.8g, 0.6mol) in 120ml toluene, heat until reflux, and stir vigorously to form a suspension of powdery sodium, then add triphenylphosphine dropwise under vigorous stirring (13.1g, 0.05mol), after dropping, add 6ml of tert-butanol and heat to reflux for reaction. After the reaction of triphenylphosphine is complete, cool down to room temperature, add phosphorus trichloride (13.7g, 0.1mol) dropwise, and Vigorously stir the reaction during the addition process, and heat to 100°C for the reaction after dropping, and monitor the reaction by TLC;

[0034] 2) Cool the mixture obtained in step 1) to 80°C, add 2,4,6-trimethylbenzoyl chloride (54.8g, 0.3mol) dropwise at this temperature, and react after dropping, keep warm for reaction, after the reaction is complete , add water to the reaction system, stir and reac...

Embodiment 2

[0036] The preparation method of embodiment 2 phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide

[0037] 1) Under the protection of nitrogen, suspend metal sodium block (13.8g, 0.6mol) in 120ml toluene, heat until reflux, and stir vigorously to form a suspension of powdery sodium, then add triphenylphosphine dropwise under vigorous stirring (13.1g, 0.05mol), after dropping, add 6ml of tert-butanol and chlorobenzene (3.2g, 0.03mol), heat to reflux for reaction, when the reaction of triphenylphosphine is complete, cool down to room temperature, add dropwise phosphorus trichloride ( 13.7g, 0.1mol), vigorously stir the reaction during the dropwise addition, heat to 100°C for the reaction after the dropwise addition, and monitor the reaction by TLC;

[0038] 2) Cool the mixture obtained in step 1) to 80°C, add 2,4,6-trimethylbenzoyl chloride (54.8g, 0.3mol) dropwise at this temperature, and react after dropping, keep warm for the reaction, after the reaction is complete , add wa...

Embodiment 3

[0040] The preparation method of embodiment 3 phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide

[0041] 1) Under the protection of nitrogen, suspend metal sodium block (13.8g, 0.6mol) in 120ml ethylbenzene, heat until reflux, and stir vigorously to form a suspension of powdery sodium, then add triphenyl triphenyl under vigorous stirring Phosphine (13.1g, 0.05mol), after dropping, add 6ml of tert-butanol and chlorobenzene (3.2g, 0.03mol), heat and reflux for reaction, when the reaction of triphenylphosphine is complete, cool down to room temperature, add phosphorus trichloride dropwise (13.7g, 0.1mol), stirred vigorously during the dropwise addition, heated to 100°C for reaction after dropping, and monitored the reaction by TLC;

[0042] 2) Cool the mixture obtained in step 1) to 80°C, add 2,4,6-trimethylbenzoyl chloride (54.8g, 0.3mol) dropwise at this temperature, and react after dropping, keep warm for the reaction, after the reaction is complete , add water to the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com