A kind of organosilicon modified aqueous polyurethane emulsion and preparation method thereof

A water-based polyurethane and silicone technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of water-based polyurethane with poor water resistance, poor stability, and poor solvent resistance, and achieve excellent weather resistance and water resistance. Decreased water resistance and low surface tension effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

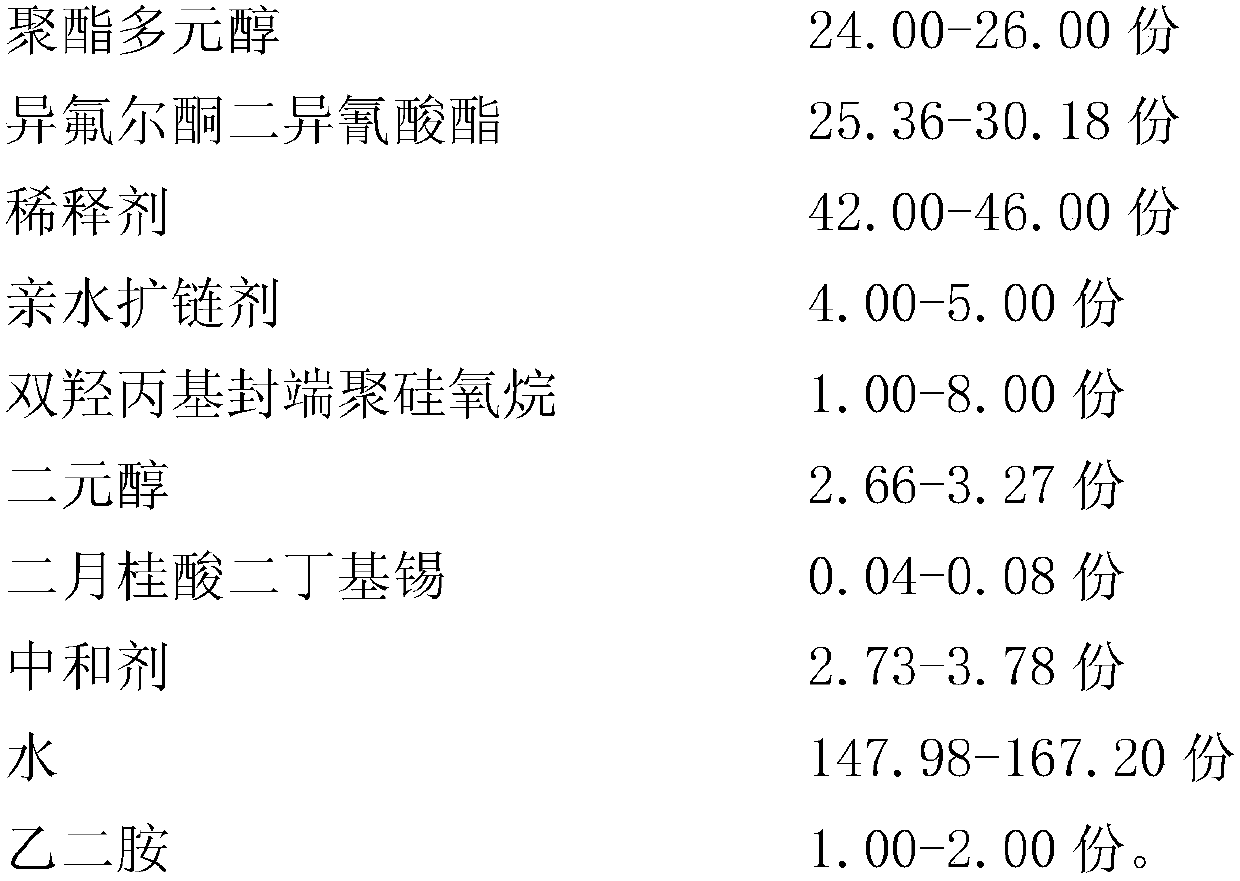

[0048] A silicone-modified polyurethane emulsion, characterized in that: it is formulated from the following components in the following parts by weight:

[0049]

[0050] A silicone-modified polyurethane emulsion, characterized in that: the silicone-modified polyurethane emulsion is prepared according to the following steps in sequence:

[0051] 1) Preparation of polyurethane prepolymer:

[0052] Add 24.00-26.00 parts of polyester polyol and 25.36-30.18 parts of isophorone diisocyanate into the reactor, heat to 80-85 ° C under the stirring speed of 300-500 rpm and nitrogen protection, and react until the measured -NCO The content reaches the theoretical value;

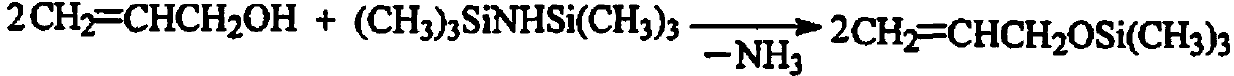

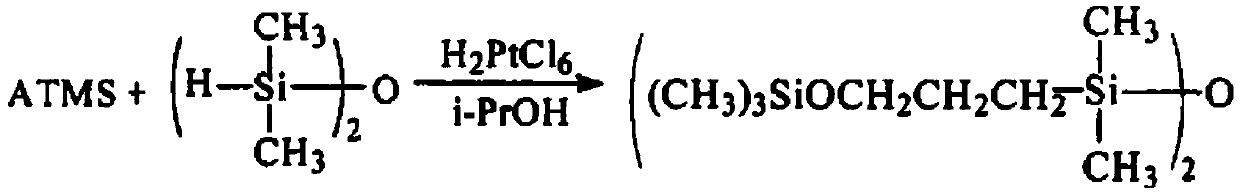

[0053] 2) Preparation of organosilicon-modified polyurethane prepolymer:

[0054] Then, keep the above speed and temperature, add 42.00-46.00 parts of diluent to adjust the viscosity of the system, then add 4.00-5.00 parts of hydrophilic chain extender, 1.00-8.00 parts of silicone and 0.04-0.08 parts of dilauric ac...

Embodiment 1

[0060] A silicone-modified water-based polyurethane emulsion, which is formulated by the following components in the following parts by weight ratio:

[0061]

[0062] A kind of preparation of organosilicon modified water-based polyurethane emulsion, it is prepared according to the following steps carried out in order by the raw material of following weight ratio:

[0063] 1) Preparation of polyurethane prepolymer:

[0064] Add 24.00 parts of polyester polyol and 25.36 parts of isophorone diisocyanate into a 500mL four-necked flask equipped with a stirrer, thermometer, and condenser tube, heat to 80°C at a stirring speed of 300rpm and under nitrogen protection, and react to the The measured -NCO content reached the theoretical value (15.33%).

[0065] 2) Preparation of organosilicon-modified polyurethane prepolymer:

[0066] Add 42 parts of diluent to the above reaction system to adjust the viscosity of the system, then add 4 parts of hydrophilic chain extender 2,2-dimeth...

Embodiment 2

[0070] A silicone-modified water-based polyurethane emulsion, which is formulated by the following components in the following parts by weight ratio:

[0071]

[0072] A kind of preparation of organosilicon modified water-based polyurethane emulsion, it is prepared according to the following steps carried out in order by the raw material of following weight ratio:

[0073] 1) Preparation of polyurethane prepolymer:

[0074] Add 26 parts of polyester polyol and 30.18 parts of isophorone diisocyanate into a 500mL four-necked flask equipped with a stirrer, thermometer, and condenser tube, heat to 85°C at a stirring speed of 500rpm and under nitrogen protection, and react to the The measured -NCO content reached the theoretical value (16.41%).

[0075] 2) Silicone modified polyurethane prepolymer:

[0076] Add 46 parts of diluent to the reaction system to adjust the viscosity of the system, then add 5 parts of hydrophilic chain extender 2,2-dimethylolpropionic acid (DMPA), 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com