A wood plastic composite and a preparing method thereof

A wood-plastic composite material and plastic powder technology, which is applied in the field of wood-plastic composite materials, can solve the problems of difficulty in adding straw fibers and red mud, poor fluidity of waste PVC plastics, and low amount of waste added, and achieves designability. , Improve the surface brightness and smoothness, the effect of high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

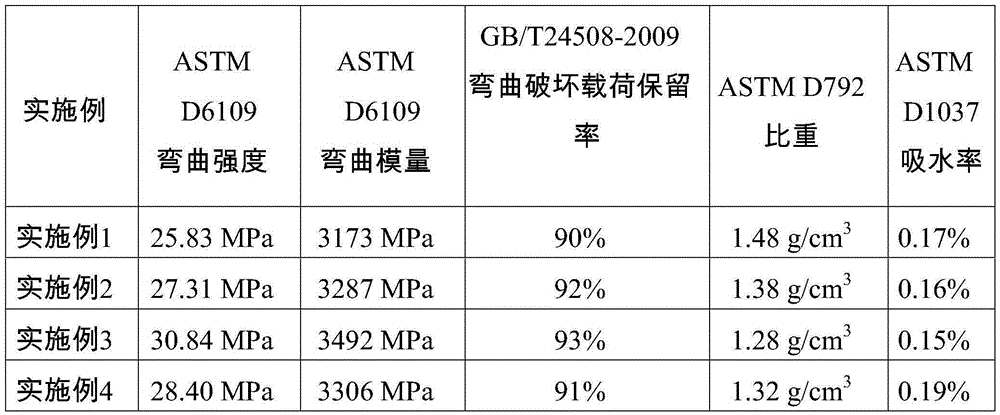

Examples

Embodiment 1

[0041] Embodiment 1: take each raw material by following weight fraction:

[0042]50 parts of PVC resin powder; 20 parts of straw powder; 50 parts of waste PVC plastic powder; 60 parts of red mud; 5 parts of nano calcium carbonate; 3 parts of stabilizer; 3 parts of acrylate processing modifier ACR; 0.5 part of stearic acid; 0.5 parts of polyethylene wax; 1 part of impact modifier MBS;

[0043] The particle size range of the straw powder is 80-120 mesh; the stabilizer can be dust-free composite lead salt stabilizer and / or dust-free rare earth composite stabilizer; the impact modifier MBS is methyl methacrylate Graft copolymer of esters, butadiene and styrene.

[0044] Produced according to the following method: the moisture content of nano calcium carbonate is not higher than 5% when used;

[0045] (1) The particle size of straw powder is 80-120 mesh, and the particle size range of red mud is 400-800 mesh;

[0046] (2) Mix various raw materials and knead them in a Z-type kne...

Embodiment 2

[0049] Embodiment 2: take each raw material by following weight fraction:

[0050] 50 parts of PVC resin powder; 30 parts of straw powder; 50 parts of waste PVC plastic powder; 40 parts of red mud; 7 parts of nano-calcium carbonate; 5 parts of stabilizer; 5 parts of acrylate processing modifier ACR; 1 part of stearic acid; 1 part of polyethylene wax; 5 parts of impact modifier MBS;

[0051] The particle size range of the straw powder is 80-120 mesh; the stabilizer can be dust-free composite lead salt stabilizer and / or dust-free rare earth composite stabilizer; the impact modifier MBS is methyl methacrylate Graft copolymer of esters, butadiene and styrene.

[0052] Produced according to the following method: the moisture content of nano calcium carbonate is not higher than 5% when used;

[0053] (1) The particle size of straw powder is 80-120 mesh, and the particle size range of red mud is 400-800 mesh;

[0054] (2) Mix various raw materials and knead them in a Z-type kneade...

Embodiment 3

[0057] Embodiment 3: take each raw material by following weight fraction:

[0058] 50 parts of PVC resin powder; 60 parts of straw powder; 50 parts of waste PVC plastic powder; 20 parts of red mud; 8 parts of nano calcium carbonate; 7 parts of stabilizer; 8 parts of acrylate processing modifier ACR; 1.5 parts of stearic acid; 1.5 parts of polyethylene wax; 9 parts of impact modifier MBS;

[0059] The particle size range of the straw powder is 80-120 mesh; the stabilizer can be dust-free composite lead salt stabilizer and / or dust-free rare earth composite stabilizer; the impact modifier MBS is methyl methacrylate Graft copolymer of esters, butadiene and styrene.

[0060] Produced according to the following method: the moisture content of nano calcium carbonate is not higher than 5% when used;

[0061] (1) The particle size of straw powder is 80-120 mesh, and the particle size range of red mud is 400-800 mesh;

[0062] (2) Mix various raw materials and knead them in a Z-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com