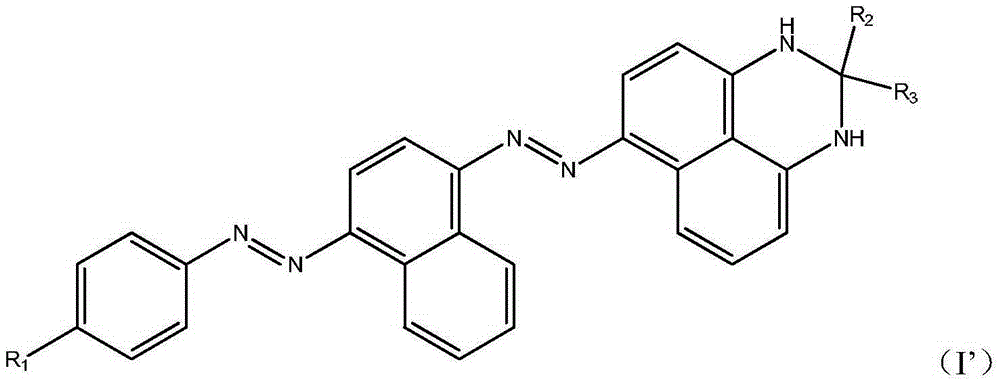

Bisazo purple dye and application thereof

A purple dye and disazo technology, applied in disazo dyes, applications, household appliances, etc., can solve the problem of unsatisfactory solubility and achieve the effect of high solubility and improved affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

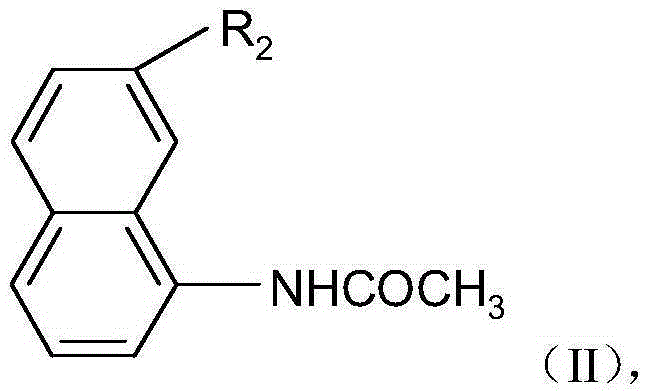

[0046] Weigh 1.0g (5mmol, 201g / mol) 1-acetylamino-7-naphthol, 1.92g (10mmol, 192g / mol) bromoisoctane, 1.38g (10mmol, 138g / mol) K 2 CO 3 Dissolved in 50mL of acetonitrile, reflux for 9h. Developing agent: acetone / petroleum ether=1 / 2 (volume ratio), Rf raw material=0.13, Rf product=0.55. After the reaction, the product was poured into 100 mL of water to precipitate an oily product, and the product was extracted with ethyl acetate, and the solvent and isooctane bromide were removed by rotary evaporation at 90°C to obtain the first intermediate. Yield 88%.

[0047] Weigh 0.88 g of the intermediate of the first step and dissolve it in 50 mL of isopropanol, add 20 times the amount of KOH and reflux for 5 h. Developing agent: acetone / petroleum ether=1 / 2 (volume ratio), Rf raw material=0.55, Rf product=0.63. The product solution was poured into water, extracted with ethyl acetate, and dried by rotary evaporation to obtain the second intermediate Yield 88.0%.

[0048]Weigh 2.05...

Embodiment 2

[0053] Weigh 1.0g (5mmol, 201g / mol) 1-acetylamino-7-naphthol, 1.92g (10mmol, 192g / mol) bromoisoctane, 1.38g (10mmol, 138g / mol) K 2 CO 3 Dissolved in 50mL of acetonitrile, reflux for 9h. Developing agent: acetone / petroleum ether=1 / 2 (volume ratio), Rf raw material=0.13, Rf product=0.55. After the reaction, the product was poured into 100 mL of water to precipitate an oily product, and the product was extracted with ethyl acetate, and the solvent and isooctane bromide were removed by rotary evaporation at 90°C to obtain the first intermediate. Yield 88%.

[0054] Weigh 0.88 g of the intermediate of the first step and dissolve it in 50 mL of isopropanol, add 20 times the amount of KOH and reflux for 5 h. Developing agent: acetone / petroleum ether=1 / 2 (volume ratio), Rf raw material=0.55, Rf product=0.63. The product solution was poured into water, extracted with ethyl acetate, and dried by rotary evaporation to obtain the second intermediate Yield 88.0%.

[0055] Weigh 2.0...

Embodiment 3

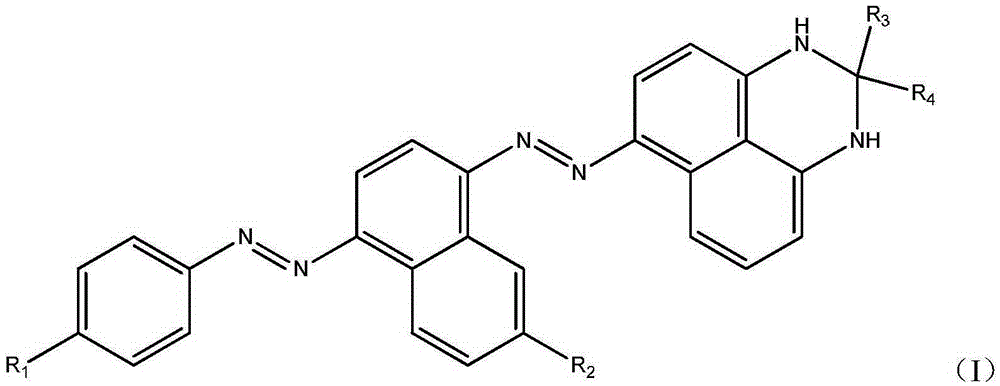

[0060] The invention provides a kind of disazo violet dye, its general chemical structure formula is as shown in (I):

[0061]

[0062] Among them, R 1 is n-butyl, R 2 is n-butoxy, R 3 is methyl, R 4 For ethyl. Get 1 mass part of disazo violet dye and dissolve it in 1 mass part of n-dodecane to obtain a kind of ink, the ink is purple, and the ink has no crystallization phenomenon when the ink is left standing at low temperature for a long time, which can effectively The ink can be applied to electrowetting display devices. Electrowetting is also called electrowetting, and the ink of the present invention is also suitable for electrowetting displays. The present invention also provides an electrowetting display, also referred to as an electrowetting display, comprising the above-mentioned ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com