Preparation method for fluoride-free super-hydrophobic cotton fabric

A cotton fabric and water cotton technology, applied in the field of fluorine-free super-hydrophobic cotton fabric and its preparation, can solve the problems of reducing the effect of hydrophobicity, affecting the environment, increasing costs, etc., and achieving the effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

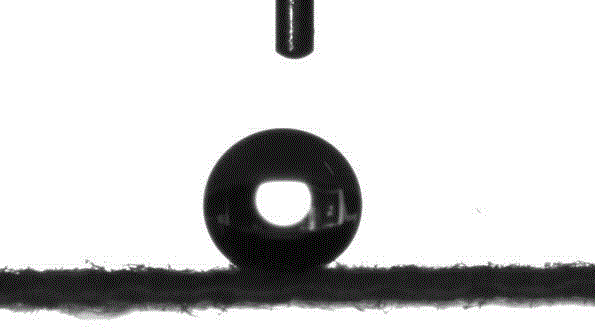

Image

Examples

Embodiment 1

[0017] The preparation method of the fluorine-free superhydrophobic cotton fabric of the present embodiment, the steps are as follows:

[0018] Mix 19mL of glacial acetic acid with 235mL of distilled water, and record it as solution A; mix 60g of butyl titanate with 19mL of glacial acetic acid, and record it as solution B; put solution A in an ice bath, and add solution B to A solution dropwise. solution, and electric stirring for 2h, and then static layering, the lower layer of translucent liquid is TiO 2 Hydrosol. TiO with distilled water 2 Hydrosol dilution is 0.5%. The cotton fabric was impregnated with 0.5% nano-TiO 2 5 minutes in the sol, using the two dipping and two rolling method, the excess rate is controlled at 70%, and the nano TiO 2 The cotton fabric of the sol was first dried at 80°C, and then baked at 140°C for 3 minutes. Apply solid paraffin to the paper to make waxed paper, then mix the waxed paper with TiO 2 The surface of the sol-treated cotton fabric ...

Embodiment 2

[0020] The preparation method of the fluorine-free superhydrophobic cotton fabric of the present embodiment, the steps are as follows:

[0021] Mix 19mL of glacial acetic acid and 235mL of distilled water evenly, and record it as solution A; mix 60g of butyl titanate with 19mL of glacial acetic acid, and record it as solution B; put solution A in an ice bath, and add solution B to solution A drop by drop , and electric stirring for 2h, and then static layering, the lower layer of translucent liquid is TiO 2 Hydrosol. TiO with distilled water 2 Hydrosol dilution is 1%. The cotton fabric was impregnated with 1% nano-TiO 2 5 minutes in the sol, using the two dipping and two rolling method, the excess rate is controlled at 70%, and the nano TiO 2 The cotton fabric of the sol was first dried at 80°C, and then baked at 140°C for 3 minutes. Apply solid white wax to the paper to make waxed paper, and then mix the waxed paper with TiO 2 The surface of the sol-treated cotton fabri...

Embodiment 3

[0023] The preparation method of the fluorine-free superhydrophobic cotton fabric of the present embodiment, the steps are as follows:

[0024] Mix 19mL of glacial acetic acid and 235mL of distilled water evenly, and record it as solution A; mix 60g of butyl titanate with 19mL of glacial acetic acid, and record it as solution B; put solution A in an ice bath, and add solution B to solution A drop by drop , and electric stirring for 3h, and then static layering, the lower layer of translucent liquid is TiO 2 Hydrosol. TiO with distilled water 2 Hydrosol dilution is 1%. The cotton fabric was impregnated with 1% nano-TiO 2 10 minutes in the sol, using the two dipping and two rolling method, the excess rate is controlled at 80%, and the nano TiO 2 The cotton fabric of the sol was first dried at 70°C, and then baked at 140°C for 5min. Apply solid paraffin to paper to make stenciled paper, and then stenciled the stenciled paper with TiO 2 The surface of the sol-treated cotton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com