A kind of superhydrophobic self-cleaning coating and preparation method thereof

A self-cleaning coating and super-hydrophobic technology, applied in the direction of coating, etc., can solve the problems of complex preparation process, environmental pollution, high price, etc., and achieve the effect of wide application prospect, expanded application range, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a superhydrophobic self-cleaning coating, comprising the following steps:

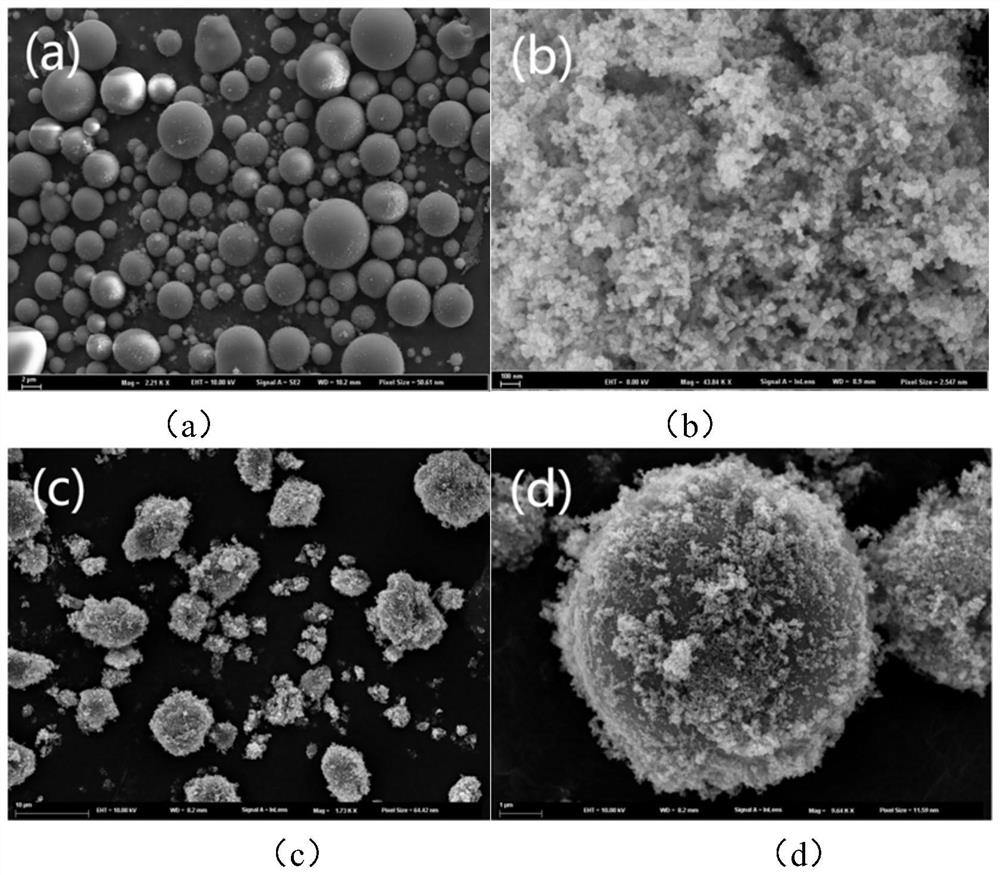

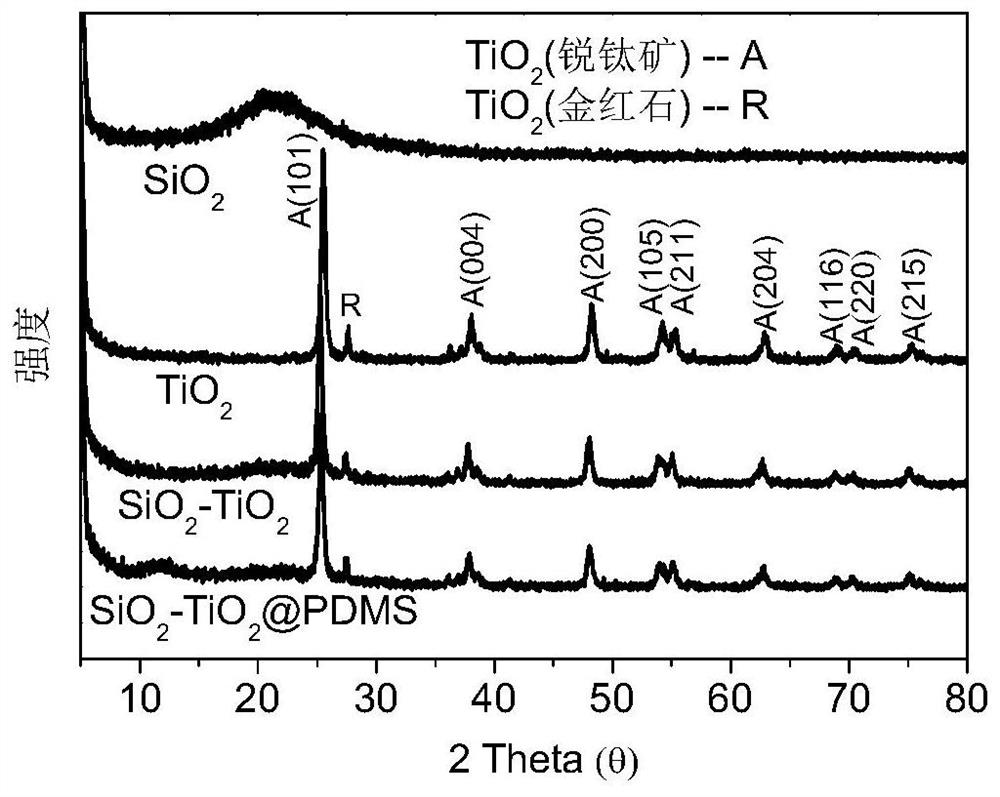

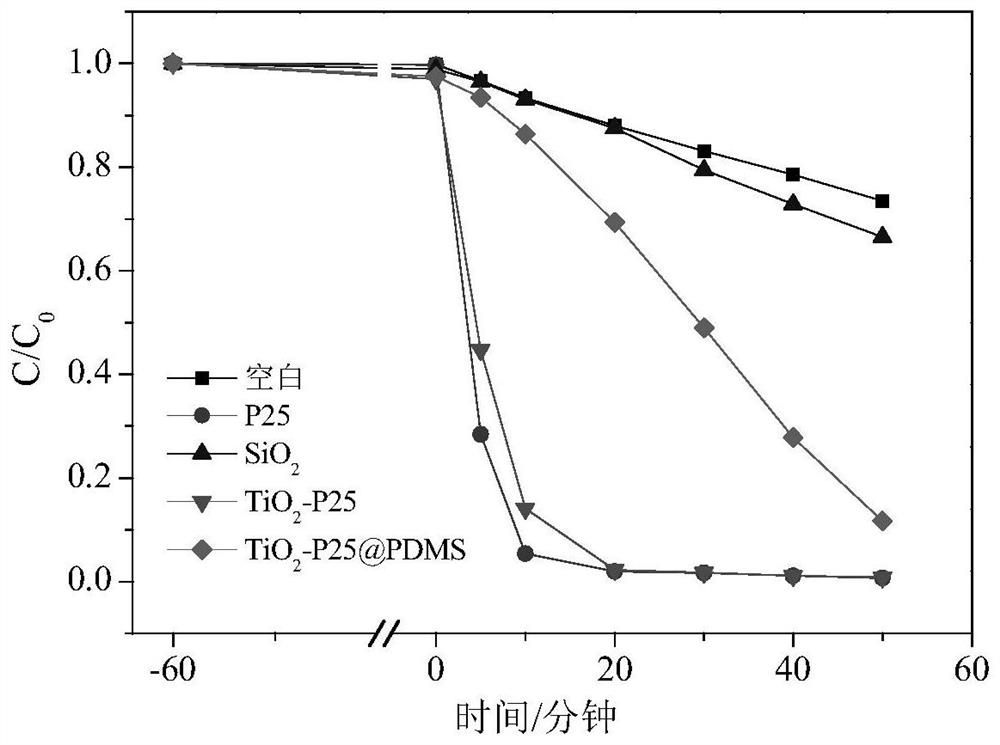

[0039] (1) SiO 2 and TiO 2 Modification: SiO 2 and TiO 2 Put into two beakers respectively, SiO 2 and TiO 2 The mass ratio is 8:2; Add a small amount of distilled water to disperse it, then add sodium oleate and sodium stearate respectively in two beakers, the quality of adding sodium oleate and sodium stearate is respectively SiO 2 and TiO 2 1% by mass, stirred for 1h; where TiO 2 I am using P25;

[0040] (2) SiO 2 -TiO 2 Preparation of composite powder: the modified TiO 2 The suspension was added to the SiO 2 In the suspension, stir vigorously for 90min, wash with distilled water three times, dry at 105°C, and form SiO after grinding 2 -TiO 2 Composite powder;

[0041] (3) Modification of low surface energy substances: SiO 2 -TiO 2 Disperse the composite powder in absolute ethanol, add PDMS, stir for 1h to form SiO 2 -TiO 2 @PDMS slurry, where SiO 2 -T...

Embodiment 2

[0050] A method for preparing a superhydrophobic self-cleaning coating, comprising the following steps:

[0051] (1) SiO 2 and TiO 2 Modification: SiO 2 and TiO 2 Put into two beakers respectively, SiO 2 and TiO 2 The mass ratio of is 8:2; Make it disperse with a small amount of distilled water, then add sodium stearate in above-mentioned beaker, the quality of adding sodium stearate is SiO 2 and TiO 2 1% of mass, stir for 1h;

[0052] (2) SiO 2 -TiO 2 Preparation of composite powder: the modified TiO 2 The suspension was added to the SiO 2 In the suspension, stir vigorously for 90min, wash with distilled water three times, dry at 105°C, and form SiO after grinding 2 -TiO 2 Composite powder;

[0053] (3) Modification of low surface energy substances: SiO 2 -TiO 2 Disperse the composite powder in absolute ethanol, add PDMS, stir for 1h to form SiO 2 -TiO 2 @PDMS slurry. SiO 2 -TiO 2 The mass ratio of composite powder, absolute ethanol and PDMS is 4:20:1.

...

Embodiment 3

[0058] (1) SiO 2 and TiO 2 Modification: SiO 2 and TiO 2 Put into two beakers respectively, SiO 2 and TiO 2 The mass ratio of is 8:2; Make it disperse with a small amount of distilled water, then add sodium oleate respectively in above-mentioned beaker, the quality of adding sodium oleate is respectively SiO 2 and TiO 2 1% of mass, stir for 1h;

[0059] (2) SiO 2 -TiO 2 Preparation of composite powder: the modified TiO 2 The suspension was added to the SiO 2 In the suspension, stir vigorously for 90min, wash with distilled water three times, dry at 105°C, and form SiO after grinding 2 -TiO 2 Composite powder;

[0060] (3) Modification of low surface energy substances: SiO 2 -TiO 2 Disperse the composite powder in absolute ethanol, add PDMS, stir for 1h to form SiO 2 -TiO 2 @PDMS slurry. SiO 2 -TiO 2 The mass ratio of composite powder, absolute ethanol and PDMS is 4:20:1.

[0061] (4) Preparation of super-hydrophobic coating: the glass slide was ultrasonical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com