Method for reinforcing reinforced concrete slab through prefabricating pre-stress TRC sheet

A technology of reinforced concrete slabs and concrete slabs, applied in building maintenance, construction, building construction, etc., can solve problems such as poor operability, inability to bear tension, and inconvenient operation, so as to reduce overhead construction, increase bearing capacity, and facilitate transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

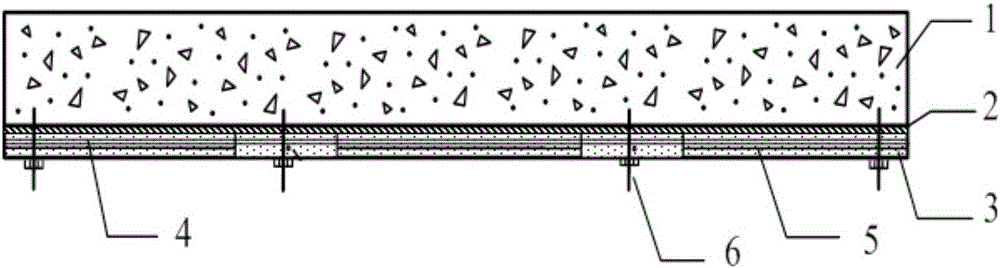

[0042]A method for prefabricating prestressed TRC slabs to strengthen reinforced concrete slabs, comprising making prestressed TRC thin slabs, interface treatment, and upward construction; the prestressed TRC thin slabs are composed of high-performance composite mortar 3, alkali-resistant fiber mesh 4 and stainless steel bars 5 , specifically made by the following steps:

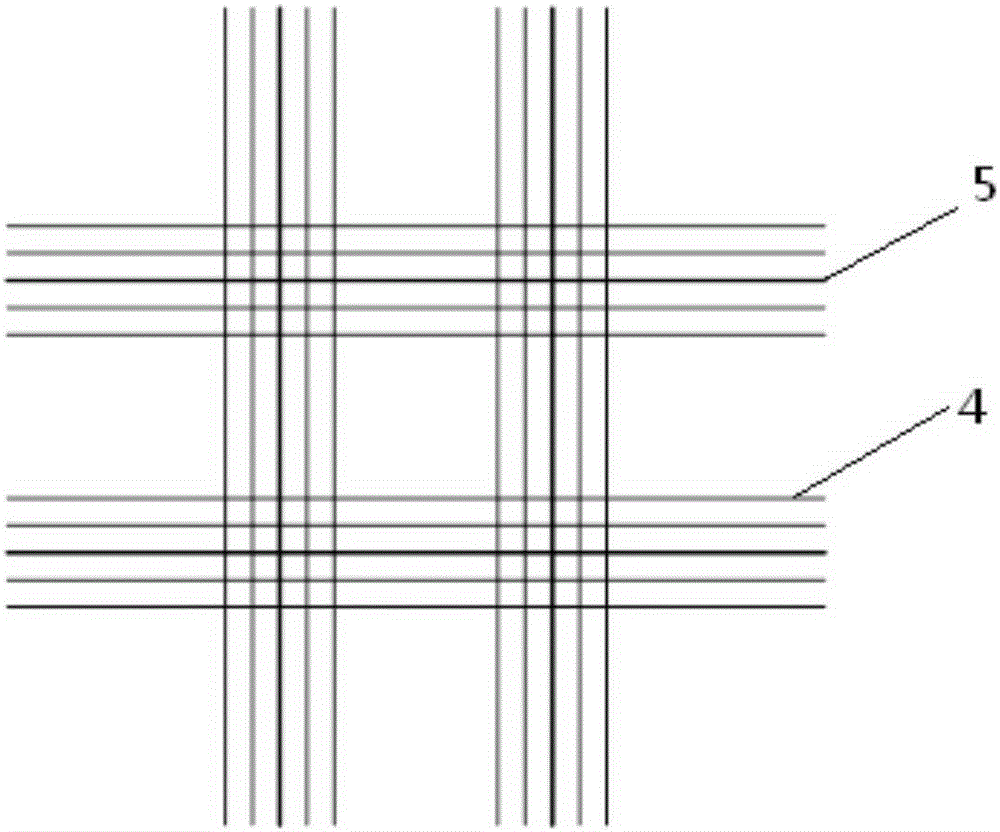

[0043] (1) Cut the alkali-resistant fiber mesh 4 into a well-shaped shape with two strips in the vertical and horizontal directions. The length L of the strips is consistent with the length of the reinforced concrete slab 1. The width of each strip is 350mm. Intersect at 1 / 5L from the end;

[0044] (2) Pierce a stainless steel bar 5 in the middle of each strip;

[0045] (3) Pour 5 mm of high-performance composite mortar 3 on the bottom formwork, place the alkali-resistant fiber mesh 4 cut in step (1) on the surface of the composite mortar, and place the end of the alkali-resistant fiber mesh 4 on the tensil...

Embodiment 2

[0055] A method for prefabricating prestressed TRC slabs to strengthen reinforced concrete slabs, comprising making prestressed TRC thin slabs, interface treatment, and upward construction; the prestressed TRC thin slabs are composed of high-performance composite mortar 3, alkali-resistant fiber mesh 4 and stainless steel bars 5 , specifically made by the following steps:

[0056] (1) Cut the alkali-resistant fiber mesh 4 into a well-shaped shape with two strips in the vertical and horizontal directions. The length L of the strips is consistent with the length of the reinforced concrete slab 1. The width of each strip is 400mm. Intersect at 1 / 4L from the end;

[0057] (2) Pierce a stainless steel bar 5 in the middle of each strip;

[0058] (3) Pour 6 mm of high-performance composite mortar 3 on the bottom formwork, place the alkali-resistant fiber mesh 4 cut in step (1) on the surface of the composite mortar, and place the end of the alkali-resistant fiber mesh 4 on the tensi...

Embodiment 3

[0068] A method for prefabricating prestressed TRC slabs to strengthen reinforced concrete slabs, comprising making prestressed TRC thin slabs, interface treatment, and upward construction; the prestressed TRC thin slabs are composed of high-performance composite mortar 3, alkali-resistant fiber mesh 4 and stainless steel bars 5 , specifically made by the following steps:

[0069] (1) Cut the alkali-resistant fiber mesh 4 into a well-shaped shape with two strips in the vertical and horizontal directions. The length L of the strips is consistent with the length of the reinforced concrete slab 1. The width of each strip is 450mm. Intersect at 1 / 4L from the end;

[0070] (2) Pierce a stainless steel bar 5 in the middle of each strip;

[0071] (3) Pour 7 mm of high-performance composite mortar 3 on the bottom formwork, place the alkali-resistant fiber mesh 4 cut in step (1) on the surface of the composite mortar, and place the end of the alkali-resistant fiber mesh 4 on the tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com