Color wheel and laser light source

A color wheel and laser technology, used in optics, instruments, projection devices, etc., can solve the problems of complex control of dual-wavelength conversion devices, high processing and assembly requirements, and increased software complexity. The effect of miniaturization and improved color filter purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

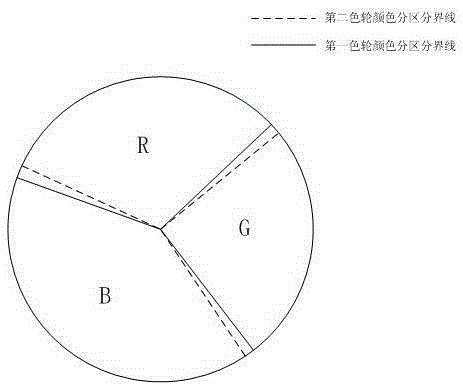

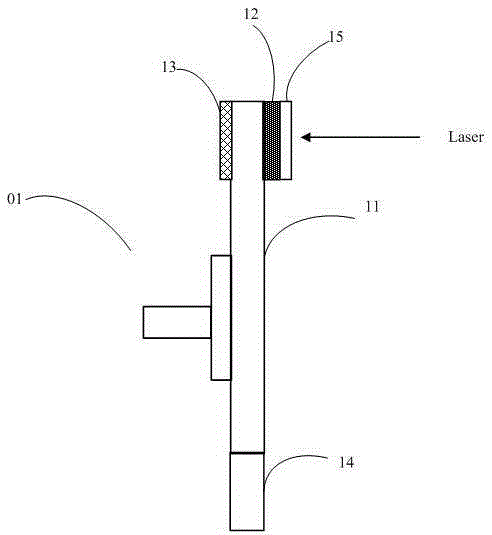

[0036] Embodiment 1 of the present invention provides a color wheel that receives laser irradiation and rotates under control, generally using a blue laser as the laser excitation light. Such as image 3 As shown, the color wheel 01 includes a substrate 11 on which a fluorescent area 12 and a transmissive area 14 are arranged. The fluorescent area 12 includes phosphor powder for generating fluorescence when irradiated by blue laser light, and the transmissive area 14 is used for transmitting blue laser light.

[0037] In one implementation, the color wheel is a transmissive fluorescent wheel, see image 3 , the substrate 11 is a transparent substrate, such as made of glass material, and has light transmission performance. The phosphor area 12 may be a phosphor layer on the transparent substrate, and the phosphor layer 12 and the transparent substrate are bonded by silica gel, which has high temperature resistance. Specifically, the phosphor layer 12 may be a fan-shaped area ...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a color wheel. The difference from Embodiment 1 is that the color wheel in this embodiment is a reflective fluorescent wheel, that is, the excited fluorescence is along the direction opposite to the incident direction of the laser light. Shooting from the front of the color wheel.

[0049] Specifically, see Figure 7 , the color wheel 01 includes a substrate 11, wherein the substrate 11 is a mirror aluminum substrate, the surface of which can reflect light. The substrate 11 includes a fluorescent area 12 and a transmissive area 14. The fluorescent area 12 includes a phosphor, usually a phosphor layer, which is glued to the laser light-incident side surface of the aluminum substrate to generate fluorescence when irradiated by blue laser light. Fluorescent light can be reflected by at least part of the above-mentioned mirror aluminum substrate, so as to emerge along the front of the color wheel. It should be noted that the m...

Embodiment 3

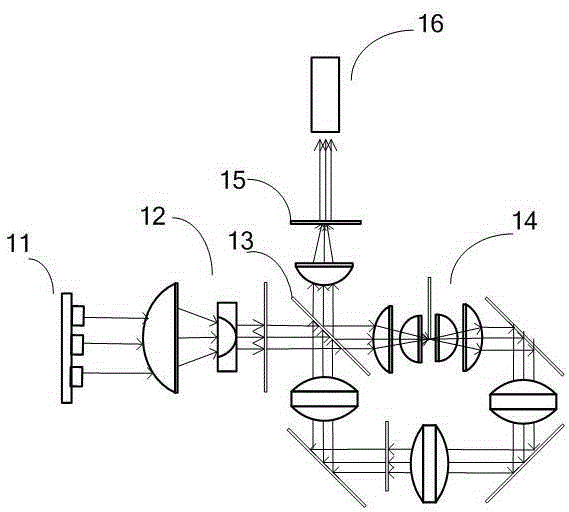

[0057] Embodiment 3 of the present invention provides a laser light source, such as Figure 8 As shown, it includes a laser group 01, specifically including a blue laser 11 and a red laser 12, which respectively emit blue laser and red laser; and a color wheel 20, wherein the color wheel 20 can be the color wheel exemplified in the above-mentioned embodiment 1 , the color wheel 20 is a transmissive phosphor wheel. Specifically, the color wheel 20 is provided with a green fluorescent powder, which can receive blue laser light and be excited to produce green fluorescence.

[0058] The blue laser needs to undergo beam shaping, such as beam reduction and homogenization, to form a smaller spot that meets the fluorescence excitation requirements, and then incident on the surface of the color wheel 20, the color wheel 20 rotates periodically, and the blue laser is incident on the color wheel in turn 20 green phosphor area and transmission area (not shown in the figure, can refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com