Teflon and polyimides combined seamless-wrapping insulated cable for aviation and spaceflight and preparation method of cable

A polytetrafluoroethylene and polyimide technology, used in insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve problems such as the limitation of insulated cables, improve shielding density, ensure shielding performance, and have a small outer diameter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

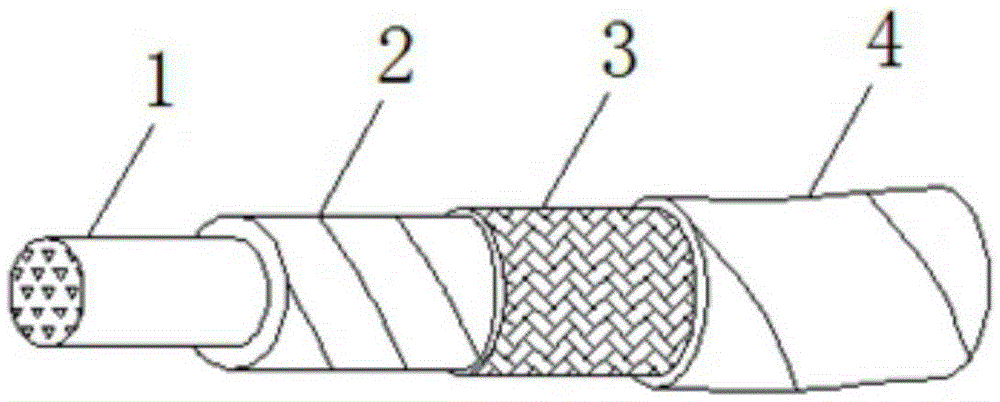

[0027] The present invention also provides a method for preparing the above-mentioned insulated cable, including:

[0028] 1) Wrap the polyimide composite film on the outside of the wire 1, then wrap the polytetrafluoroethylene film on the outside of the polyimide composite film, and then perform high temperature sintering to form an insulating sleeve on the outside of the wire 1 2;

[0029] 2) Weaving the composite polyimide wire on the outside of the insulating sleeve 2 to form the shielding sleeve 3;

[0030] 3) Wrap the polyimide composite film on the outside of the shielding sleeve 3, then wrap the polytetrafluoroethylene film on the outside of the polyimide film, and then perform high temperature sintering to form the sheath 4;

[0031] Wherein, the composite polyimide yarn contains a polyimide fiber tow and a silver-plated flat copper tape wound on the outer surface of the polyimide fiber tow, and the polyimide composite film includes successive stacking from bottom to bottom ...

preparation example 1

[0035] 1) After the round copper wire is pressed and toughened, a flat copper strip with a thickness of 0.08mm is made, and then a silver-plated flat copper strip with a thickness of 1.5μm is plated to obtain a silver-plated flat copper strip;

[0036] 2) The polyimide fiber tow is made into a polyimide fiber tow with a radius of 0.04mm, and then a silver-plated flat copper tape is wound on the outside of the polyimide fiber tow to obtain a composite polyimide 丝 C1.

preparation example 2

[0038] 1) The round copper wire is pressed and toughened to form a flat copper strip with a thickness of 0.05mm, and then plated with a silver-plated layer with a thickness of 1μm to make a silver-plated flat copper strip;

[0039] 2) The polyimide fiber tow is made into a polyimide fiber tow with a radius of 0.02mm, and then a silver-plated flat copper tape is wound on the outside of the polyimide fiber tow to obtain a composite polyimide C2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com