Surface mounting inductor manufacture method

A technology of surface mounting and manufacturing methods, applied in the direction of inductor/transformer/magnet manufacturing, coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problem of large DC resistance, increased resistance of surface mounted inductors, and discharge of organic matter Insufficient and other problems, to achieve the effect of reducing DC resistance, high performance, and small DC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: As shown in the figure, a method for manufacturing a surface mount inductor includes the following steps:

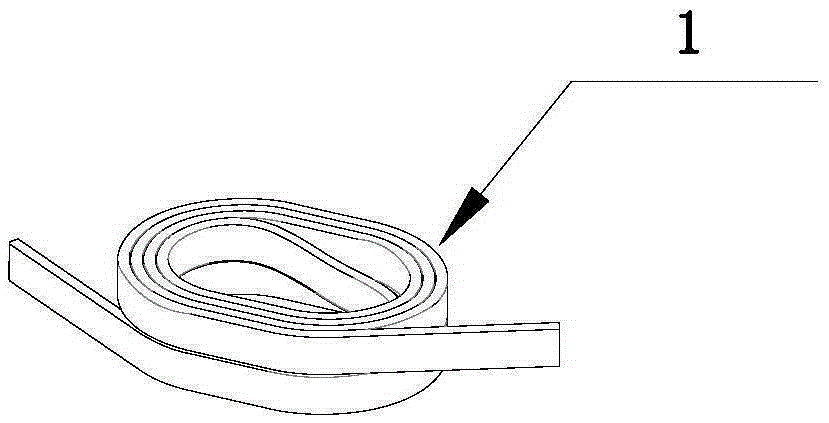

[0050] ① According to the design specifications, the enameled wire with self-adhesive layer is wound into a hollow coil 1 with leads 11 at both ends; the adhesion temperature of the self-adhesive layer of the enameled wire is 80°C to 220°C, and the temperature resistance level of the enameled wire is 155°C to 255°C .

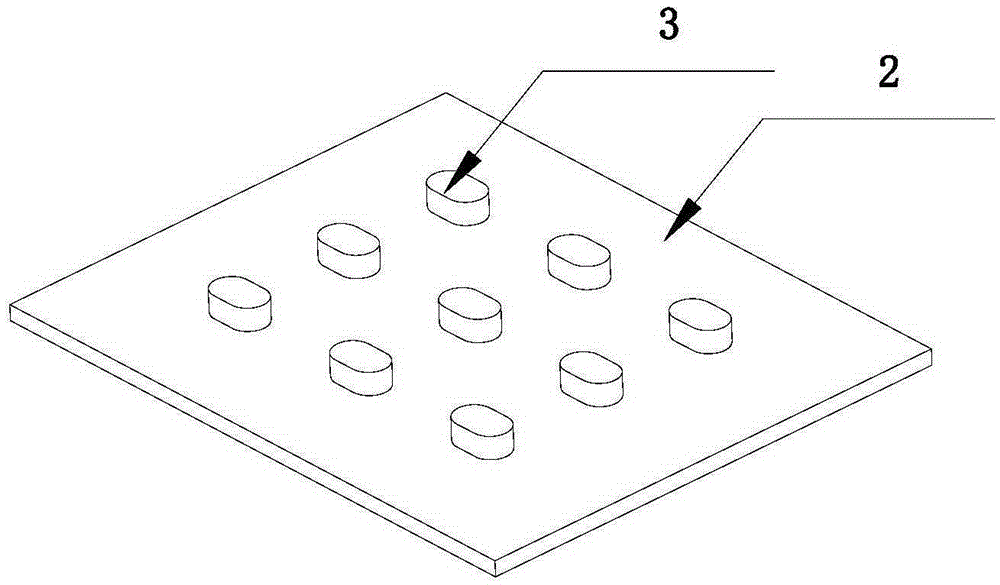

[0051] ② The base is made of magnetic powder, and the base includes a base 2 and N bosses 3 or N grooves arranged on the base 2 and arranged at intervals in an array, where N is an integer greater than or equal to 2;

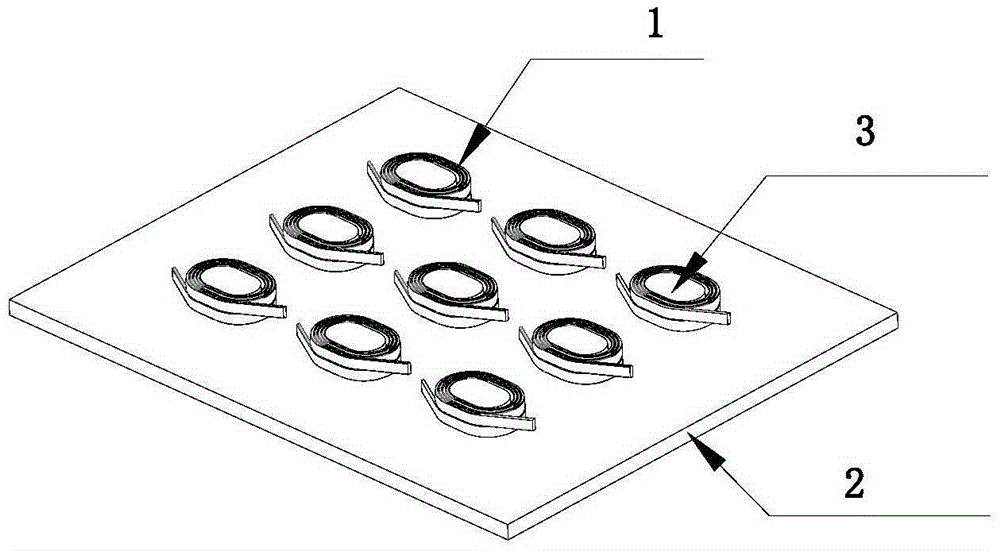

[0052] ③ Assemble the air-core coil 1 and the base: place N air-core coils 1 on the outside of N bosses 3 one by one or place N air-core coils 1 in N grooves one by one to obtain N air-core coils 1 In the assembly with the base, the N air-core coils 1 in the assembly with the base are also arranged in an array, and ther...

Embodiment 2

[0060] Embodiment 2: As shown in the figure, a method for manufacturing a surface mount inductor includes the following steps:

[0061] ① According to the design specifications, the enameled wire with self-adhesive layer is wound into a hollow coil 1 with leads 11 at both ends; the adhesion temperature of the self-adhesive layer of the enameled wire is 80°C to 220°C, and the temperature resistance level of the enameled wire is 155°C to 255°C .

[0062] ② The base is made of magnetic powder, and the base includes a base 2 and N bosses 3 or N grooves arranged on the base 2 and arranged at intervals in an array, where N is an integer greater than or equal to 2;

[0063] ③ Assemble the air-core coil 1 and the base: place N air-core coils 1 on the outside of N bosses 3 one by one or place N air-core coils 1 in N grooves one by one to obtain N air-core coils 1 In the assembly with the base, the N air-core coils 1 in the assembly with the base are also arranged in an array, and ther...

Embodiment 3

[0072] Embodiment 3: As shown in the figure, a method for manufacturing a surface mount inductor includes the following steps:

[0073] ① According to the design specifications, the enameled wire with self-adhesive layer is wound into a hollow coil 1 with leads 11 at both ends; the adhesion temperature of the self-adhesive layer of the enameled wire is 80°C to 220°C, and the temperature resistance level of the enameled wire is 155°C to 255°C .

[0074] ② The base is made of magnetic powder, and the base includes a base 2 and N bosses 3 or N grooves arranged on the base 2 and arranged at intervals in an array, where N is an integer greater than or equal to 2;

[0075] ③ Assemble the air-core coil 1 and the base: place N air-core coils 1 on the outside of N bosses 3 one by one or place N air-core coils 1 in N grooves one by one to obtain N air-core coils 1 In the assembly with the base, the N air-core coils 1 in the assembly with the base are also arranged in an array, and ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com