Tunable narrow linewidth semiconductor laser

A technology of semiconductors and lasers, applied in the field of tunable narrow-linewidth semiconductor lasers, can solve the problems of no integrated device, long length of erbium-doped fiber, and difficult calibration, etc., achieve simple docking and fixing, avoid complex optical path adjustment, and robustness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereto.

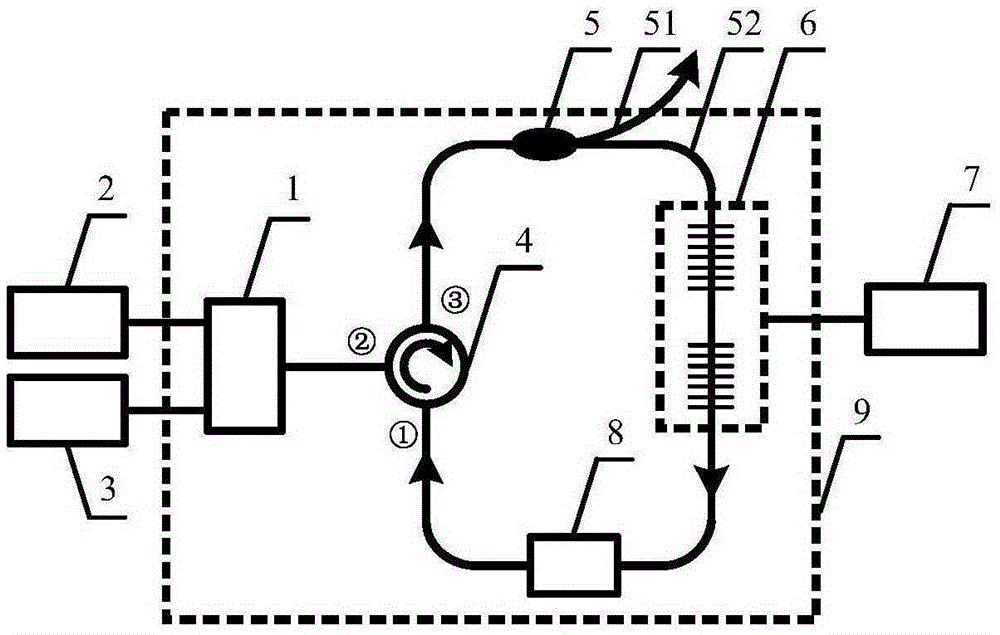

[0021] see first figure 1 , figure 1It is a schematic diagram of the overall structure of the tunable narrow linewidth semiconductor laser of the present invention. It can be seen from the figure that the composition of the tunable narrow-linewidth semiconductor laser of the present invention includes a distributed feedback semiconductor laser 1, a current driver 2, a first temperature controller 3, a polarization-maintaining fiber circulator 4, a polarization-maintaining fiber coupler 5, and a polarization-maintaining fiber Grating Fabry-Perot cavity 6, second temperature controller 7, polarization-maintaining optical fiber adjustable attenuator 8 and temperature-insulated and vibration-isolated sealed enclosure 9, the output end of the current driver 2 and the first te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com