A kind of preparation method of Camembert cheese

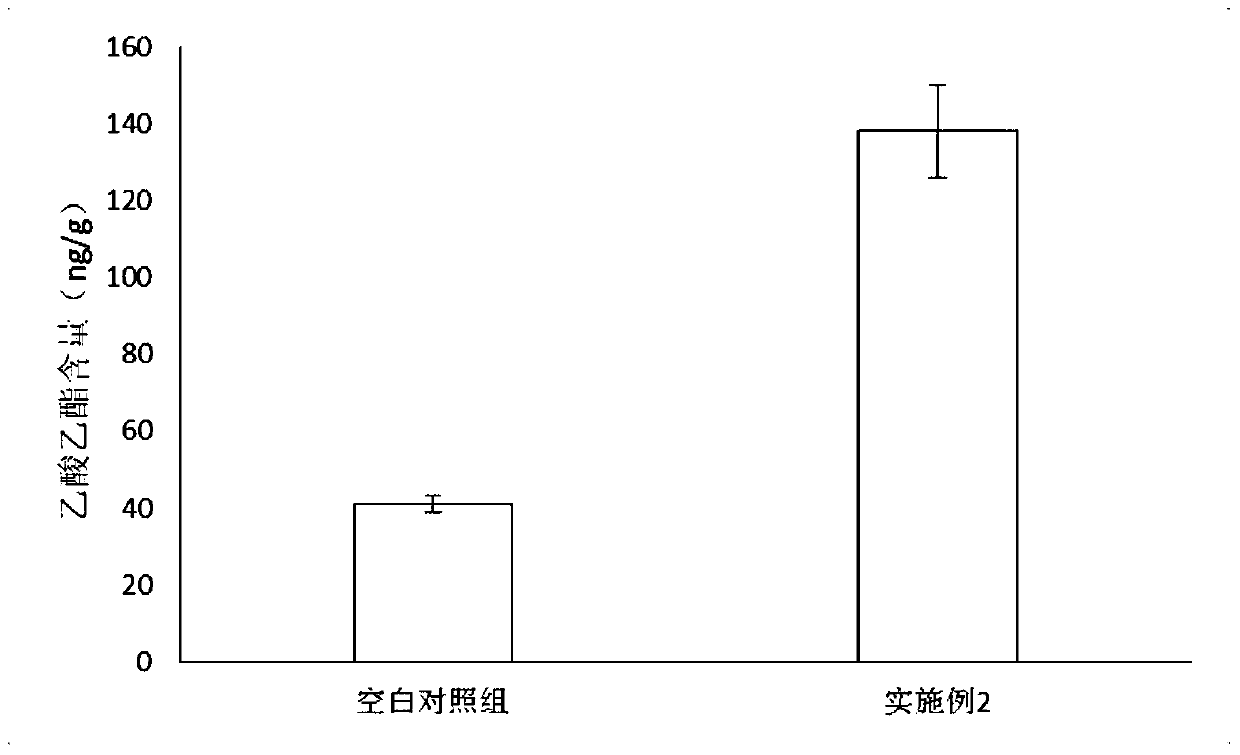

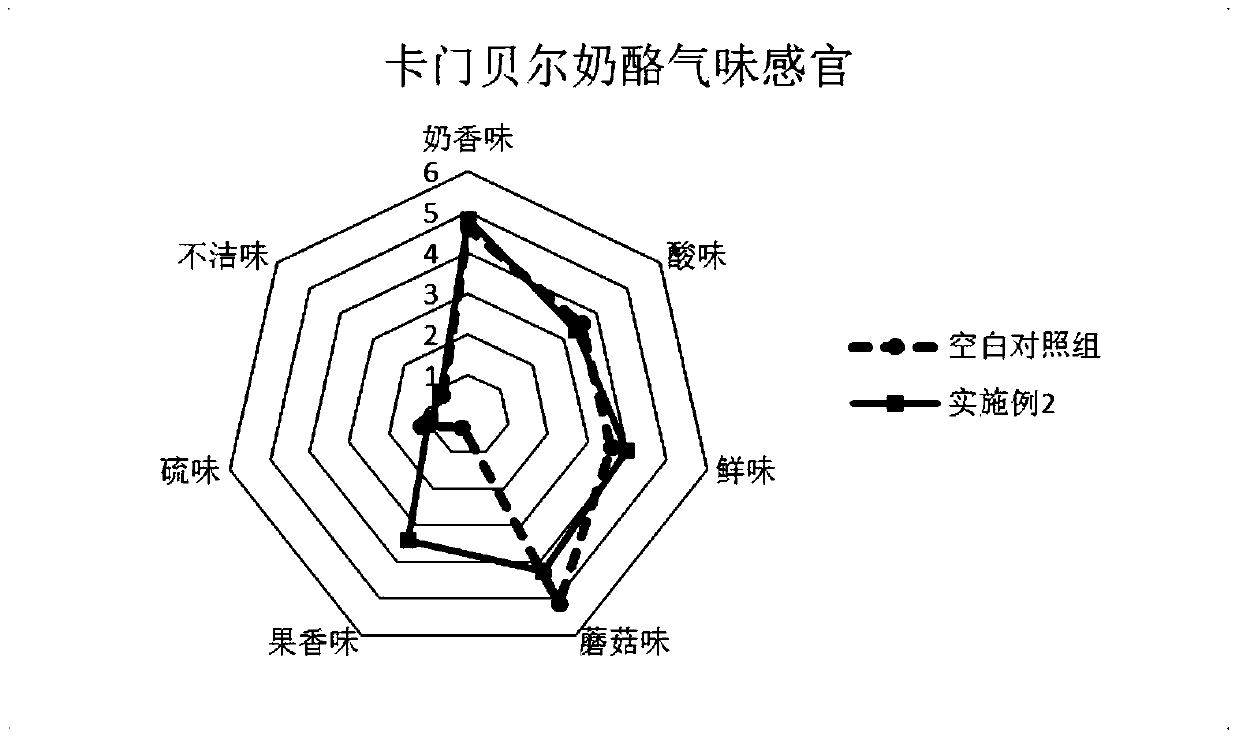

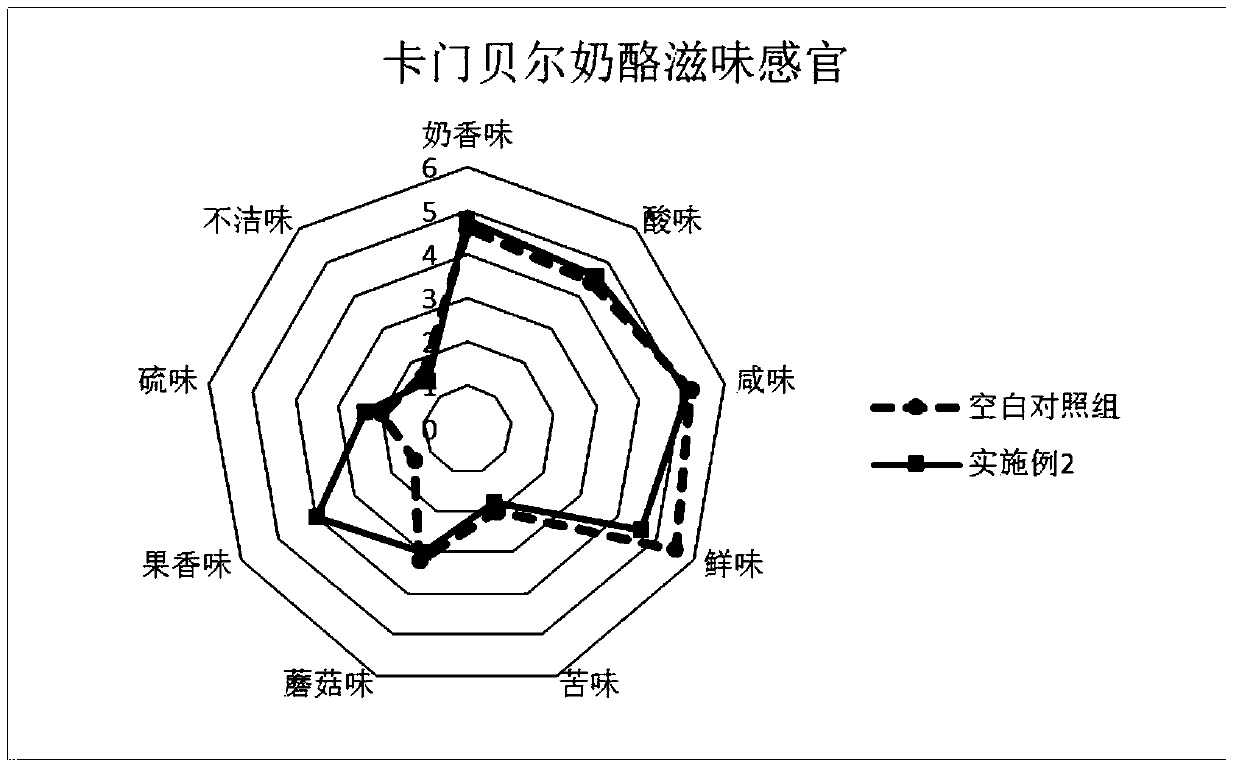

A cheese and starter technology, applied in dairy products, cheese substitutes, applications, etc., to achieve the effects of improving fruity aroma, improving viscosity and cohesion, and increasing soluble nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: add the Camembert cheese of plantaractobacillus CGMCC No.10342

[0040] 1. Preparation of Lactobacillus plantarum CGMCC No.10342 direct input working starter.

[0041] Lactobacillus plantarum CGMCC No.10342 was inoculated in MRS liquid medium with an inoculum of 2%, and cultured at 37°C for 20-24h, so that the number of viable Lactobacillus plantarum CGMCC No.10342 reached 10 8 cfu / mL or more, carry out centrifugation, centrifugation conditions: 4000rpm, 10min, 4°C, wash the precipitate twice with PBS buffer solution of pH 7.0, add lyoprotectant, adjust the cell concentration to 10 9 cfu / mL, mixed evenly, and vacuum freeze-dried to obtain the Lactobacillus plantarum CGMCC No.10342 direct-injection working starter.

[0042] 2. Production of Camembert cheese containing Lactobacillus plantarum CGMCC No.10342

[0043] The production process of Camembert cheese is as follows: the raw milk is pasteurized and cooled to 32°C quickly, adding starter, mold starter...

Embodiment 2

[0059] Embodiment 2: add the Camembert cheese of plantaractobacillus CGMCC No.10342

[0060] 1. Activation of Lactobacillus plantarum CGMCC No.10342

[0061] Purification and separation of MRS plate: Pick Lactobacillus plantarum CGMCC No.10342 with an inoculation loop under sterile conditions, streak on the MRS plate, place the plate in an incubator at 37°C for 48 hours, pick a single colony for microscopic examination, and realize the strain Purebred segregation.

[0062] Activation of the original strain: Take out the frozen strain from the -70°C refrigerator, inoculate 100 μL of the bacterial liquid into 5 mL of sterilized MRS liquid medium after thawing, grow at 37°C for 18 hours, streak, and inoculate in solid MRS at 37°C After culturing for 48 hours, a single colony was selected and inoculated in sterilized MRS liquid medium, and the experiment was carried out after three generations of activation.

[0063] MRS medium composition: 10g peptone, 10g beef extract, 5g yeas...

Embodiment 3

[0081] Embodiment 3: add the Camembert cheese of plantaractobacillus CGMCC No.10342

[0082] (1) Pretreatment of raw milk:

[0083] After the standardized raw milk is pasteurized, it is rapidly cooled to 32°C (maintain this temperature during the subsequent operation of the cheese);

[0084] (2) Addition of Lactococcus lactis starter and mold starter:

[0085] Activate Lactococcus lactis starter and mold starter strains in skim milk medium at 28-32°C for 10-12 hours, then add 2% each to raw milk, and stir evenly;

[0086] (3) Addition of auxiliary starter:

[0087] Add the activated Lactobacillus plantarum CGMCC No.10342 bacterial solution to the raw milk according to the addition amount of 5% (v / v), stir evenly, and let stand;

[0088] (4) Addition of rennet:

[0089] When the pH drops by 0.25, add 0.0015% rennet, stir evenly, and curd the milk;

[0090] (5) Cut curd, heat and stir and remove whey:

[0091] After the rennet is added, cut the curd after it is fully forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com