Betel nut aerated candy and preparation method thereof

A technology of inflatable candy and betel nut, which is applied in confectionery, confectionary industry, food science, etc., and can solve problems such as not being able to meet the requirements of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

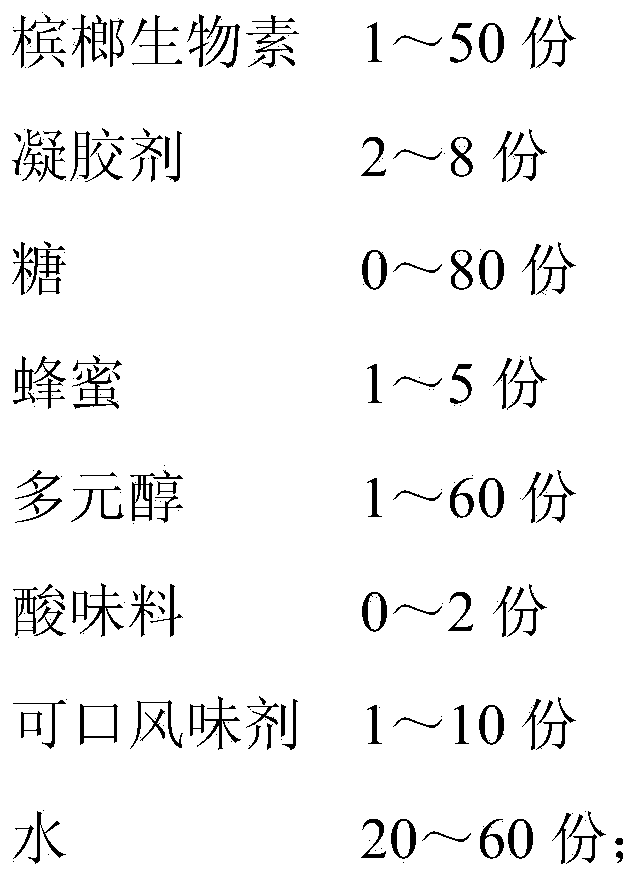

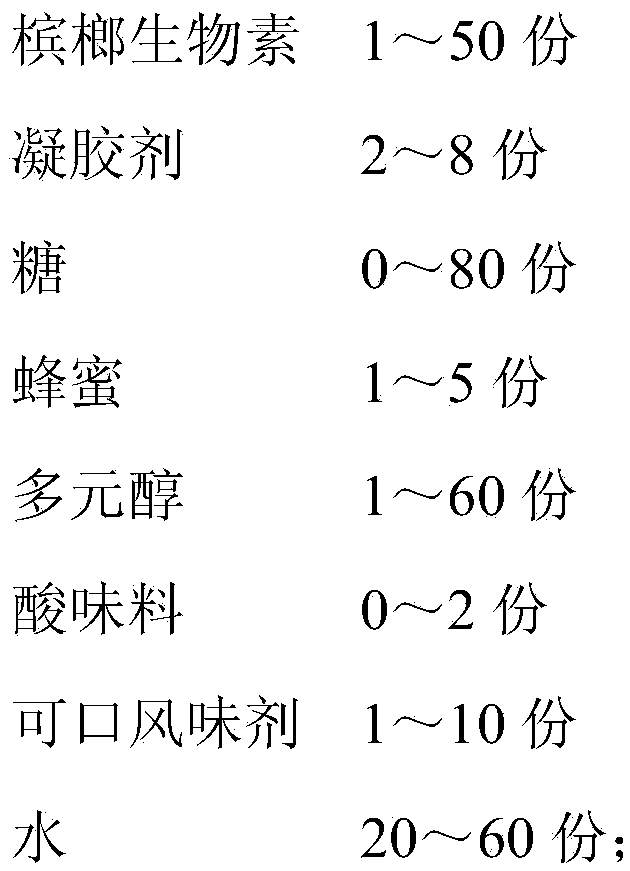

Method used

Image

Examples

Embodiment 1

[0027] Betel nut inflatable candy (betel nut coconut milk flavor)

[0028] (1) Dissolve 3.5 kg of betel nut biotin and 3 kg of gelatin in 8.5 kg of water to obtain a mixture, and heat the mixture at 60° C. for 20 minutes.

[0029] (2) Dissolve 40 kg of sucrose, 1 kg of citric acid, and 8 kg of lactitol in 31 kg of water, and heat the mixture at 80°C.

[0030] (3) Then mix (1) and (2), add 2 kg of honey and 3 kg of coconut milk and stir until a homogeneous body is obtained. Finally, the obtained homogenate is transferred to the charging hopper of a continuous pressure beater, and finally betel nut aerated candies are obtained by extrusion.

[0031] (4) After squeezing, store the strips at room temperature for 2 to 5 hours, then cut off the shape of the strips and roll them in starch.

[0032] (5) Finally, package the sample in a plastic bag and store it at room temperature.

Embodiment 2

[0034] Betel nut inflatable candy (betel nut cheese flavor)

[0035] (1) 9 kg of betel nut biotin, 2 kg of gelatin and 1 kg of pectin are dissolved in 10 kg of water to obtain a mixture, and the mixture is heated at 60° C. for 30 minutes.

[0036] (2) Dissolve 30 kg of sucrose, 1 kg of citric acid, and 8 kg of lactitol in 32 kg of water, and heat the mixture at 80°C.

[0037] (3) Then mix (1) and (2), add 4 kg of honey and 3 kg of cheese and stir until a homogeneous body is obtained. Finally, the obtained homogenate is transferred to the charging hopper of a continuous pressure beater, and finally betel nut aerated candies are obtained by extrusion.

[0038] (4) After squeezing, store the strips at room temperature for 2 to 5 hours, then cut off the shape of the strips and roll them in starch.

[0039] (5) Finally, package the sample in a plastic bag and store it at room temperature.

Embodiment 3

[0041] Betel nut inflatable candy (betel nut mango flavor)

[0042] (1) Dissolve 10 kg of betel nut biotin and 3 kg of gelatin in 12 kg of water to obtain a mixture, and heat the mixture at 60° C. for 20 minutes.

[0043] (2) Dissolve 30 kg of lactose, 0.5 kg of citric acid, and 8 kg of sorbitol in 32 kg of water, and heat the mixture at 80°C.

[0044] (3) Then mix (1) and (2), add 2 kg of honey and 2.5 kg of mango juice and stir until a homogeneous body is obtained. Finally, the obtained homogenate is transferred to the charging hopper of a continuous pressure beater, and finally betel nut aerated candies are obtained by extrusion.

[0045] (4) After squeezing, store the strips at room temperature for 2 to 5 hours, then cut off the shape of the strips and roll them in starch.

[0046] (5) Finally, package the sample in a plastic bag and store it at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com