Cleaning method of wet-type electrostatic dust collector pole plate

A wet electrostatic and dust collector technology, applied in the direction of electrode cleaning, electrostatic separation, etc., can solve the problems of unstable operation of the electric field, large space charge effect, large reactive power loss of the electric field, etc., to avoid secondary entrainment and small reactive power loss , the effect of multiple loader chances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

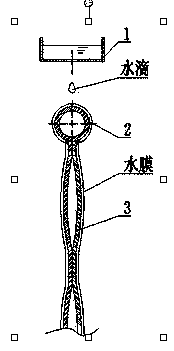

[0031] like figure 1 As shown, the material of the water delivery pipe (1) is made of metal or non-metallic corrosion-resistant materials, and it is arranged at a certain distance from the upper part of the shunt pipe (2), and its two ends are welded or clamped on the frame structure of the pole plate (3). Small drip holes or overflow holes are equidistantly arranged at the bottom or its periphery; under normal pressure and gravity, the flushing water drips or overflows to the top of the shunt pipe (2) through the small holes at the bottom or the overflow holes around it.

[0032] like figure 1 As shown, the flow equalizing pipe (2) is arranged on the top of the pole plate (3), made of stainless steel or other corrosion-resistant materials, and made into one body with the pole plate (3), for receiving water dripped from the water pipe (1) The water droplets are rinsed and distributed evenly to the plates (3).

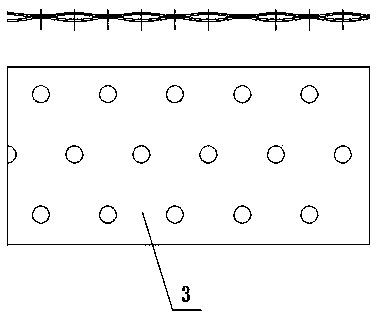

[0033] like figure 2 As shown, the pole plate (3) is made of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com