High-speed atomizer based on magnetic suspension bearing permanent magnet synchronous motor

A permanent magnet synchronous motor and magnetic suspension bearing technology, applied in the field of atomizers, can solve the problems of large rotor speed regulation range, easy wear and tear of the atomizer, and high operating costs, and achieves high operation reliability, suppression of external interference and system. Vibration, low running cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

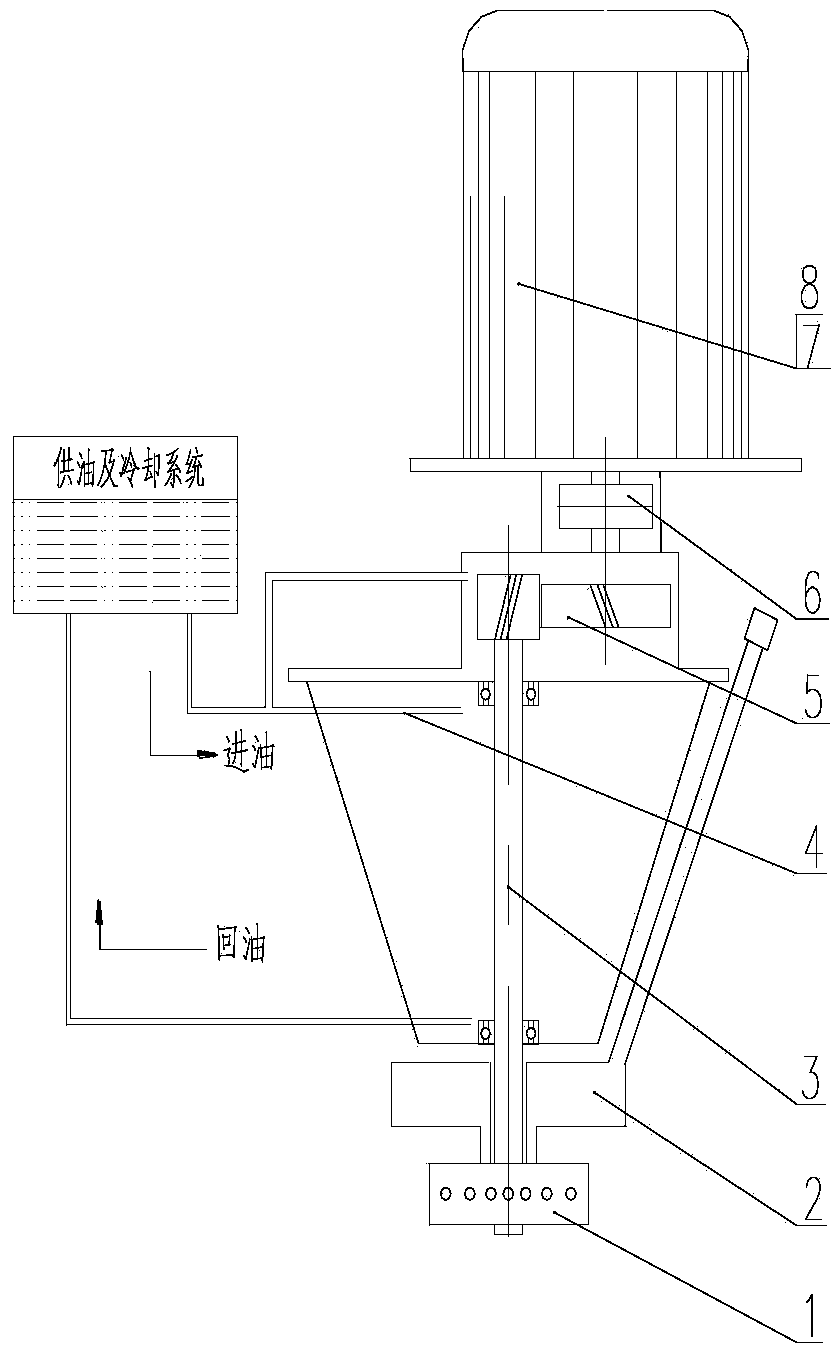

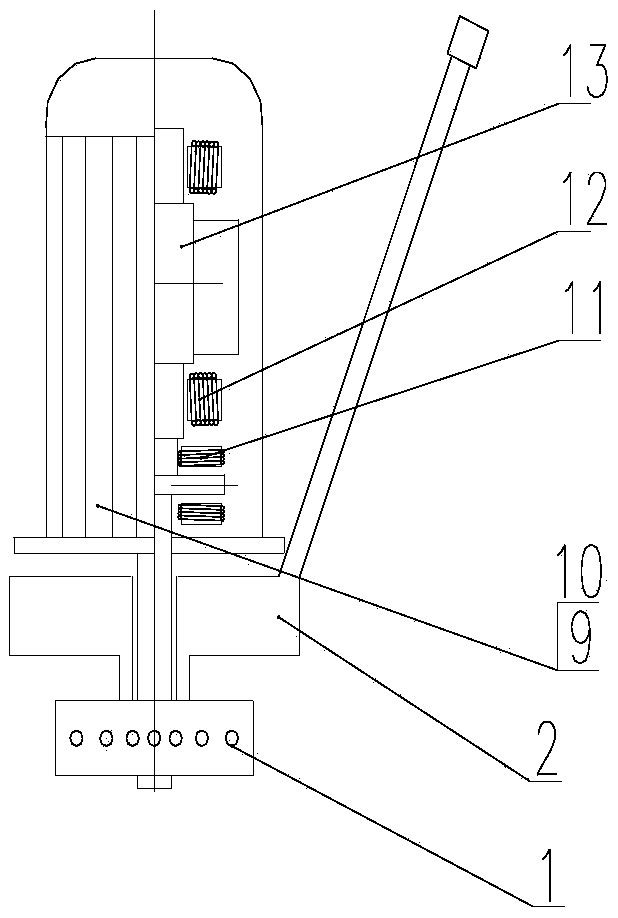

[0028] See figure 2 , is a structural schematic diagram of the present invention, a high-speed atomizer based on a magnetic suspension bearing permanent magnet synchronous motor of the present invention, including a permanent magnet synchronous motor 9, an atomizer feeding and distributing mechanism 2 and an atomizing wheel 1; the permanent magnet The synchronous motor 9 is integrated with a high-frequency power supply 10, and the permanent magnet synchronous motor 9 is provided with a magnetic levitation radial bearing 11 and a magnetic levitation axial bearing 12 to provide radial and axial support for the motor shaft 13; The atomizer feeding and distributing mechanism 2 and the atomizing wheel 1, the atomizer feeding and distributing mechanism 2 are composed of a distributor and a feeding pipe.

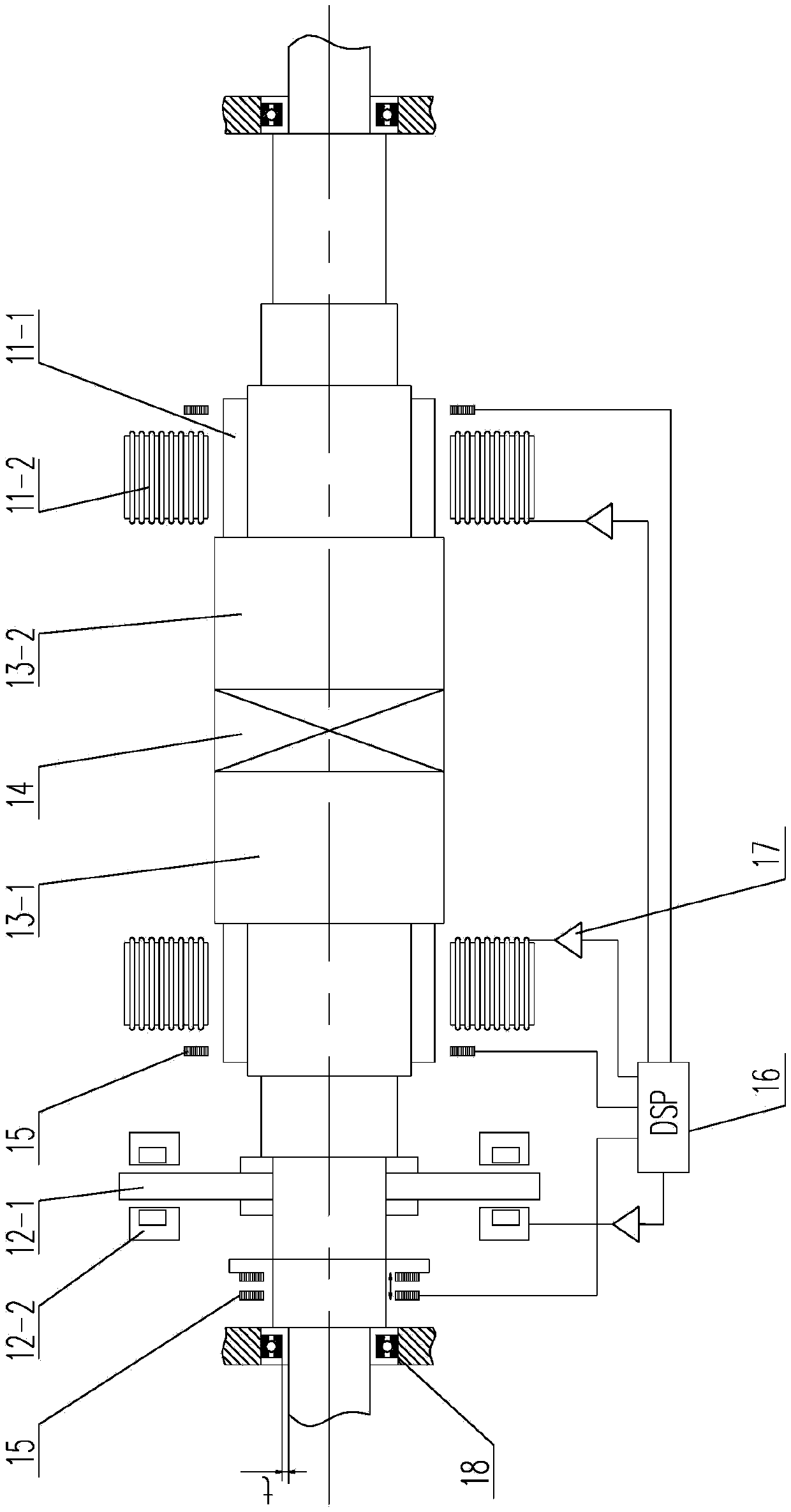

[0029] Such as image 3 As shown, the motor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com