Flat-end vertical milling cutter

A technology of flat end mills and tool holders, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc. It can solve the problems that the tools are not suitable for processing grooves, can not exert the left-handed edge to suppress burrs and delamination, and achieve the elimination of delamination and burrs, and the effect of improving surface finish quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

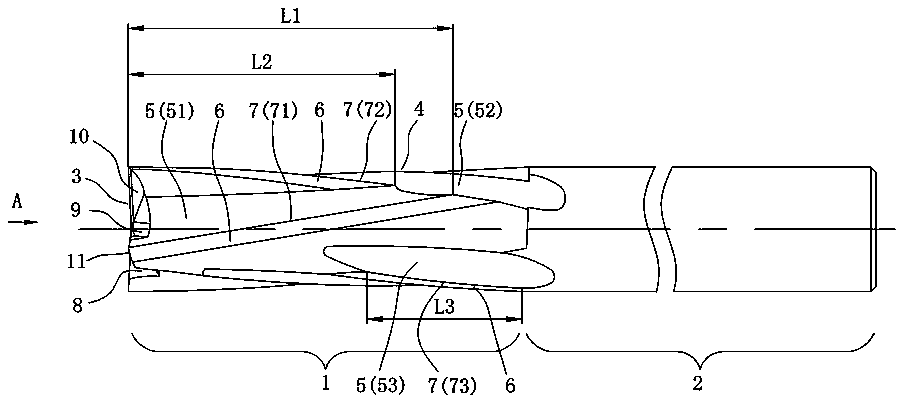

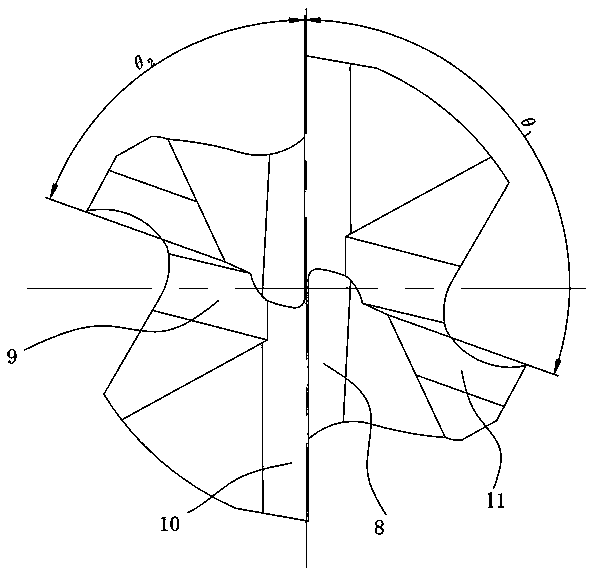

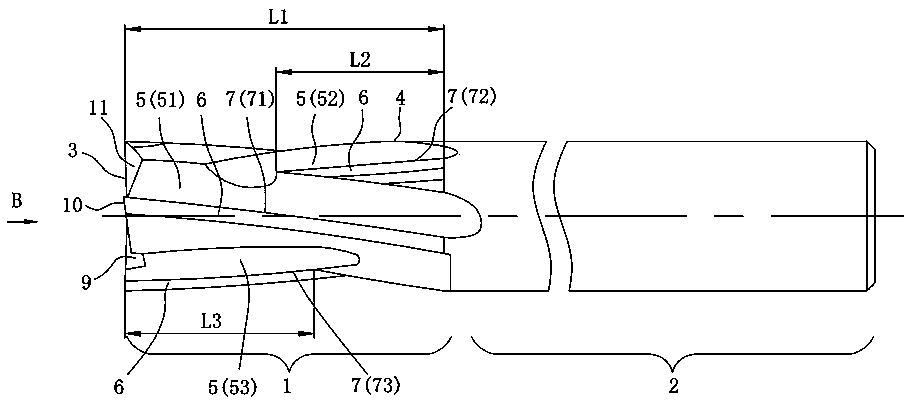

[0024] figure 1 with figure 2 Shown is a first embodiment of a flat end mill according to the invention comprising a coaxial cutting part 1 and a rotary shank 2, the cutting part 1 comprising an end part 3 and a peripheral part 4 on which There are N groups of evenly distributed spiral chip flutes 5, N≥2, in this embodiment, N is equal to 2, and the spiral chip flutes 5 include the first spiral chip flutes extending spirally from the end 3 to the rotary handle 2 51. The second helical chip flute 52 that intersects with the first helical chip flute 51 and rotates in the opposite direction and the independent third helical chip flute 53. The third helical chip flute 53 starts from the first helical chip flute 51 Before the intersection with the second spiral chip flute 52, it ends at the rotary tool handle 2, and the outer peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com