Preparation method of hollow sulfide nanometer material

A nanomaterial and sulfide technology, applied in the field of preparation of hollow sulfide nanomaterials, achieves the effects of uniform morphology, large specific surface area and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

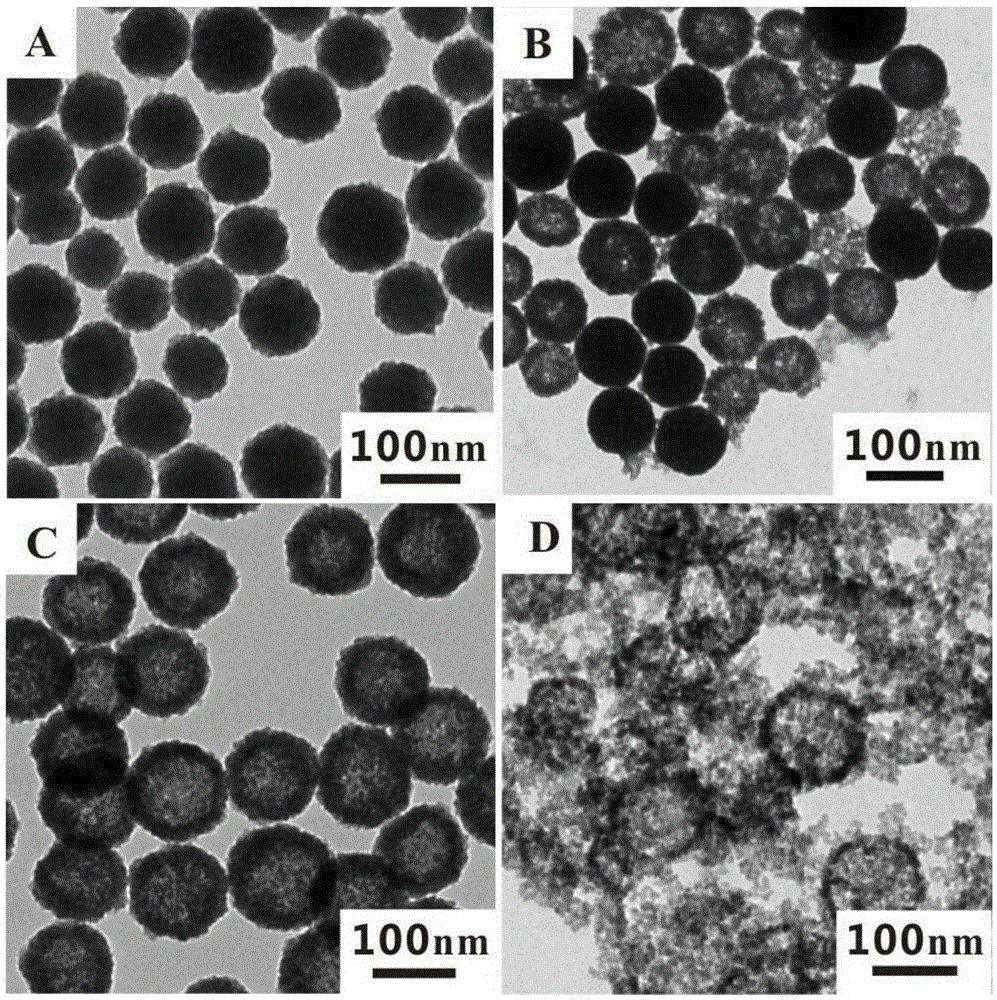

Image

Examples

Embodiment 1

[0026] 1) Preparation of solid zinc sulfide nanomaterials

[0027] According to the existing literature (XiaoxiaoYu, JiaguoYu, BeiCheng, BaibiaoHuang, One-PotTemplate-FreeSynthesis of MonodisperseZincSulfideHollowSpheres and TheirPhotocatalyticProperties.Chemistry-AEuropeanJournal, 2009, 15, 6731-6739), 0.8mmol of zinc acetate and 20mmol of thiourea were added to 20mL of water Stir at room temperature for half an hour, then transfer to a reaction kettle, react at 140°C for 50 minutes, centrifuge and wash the reacted product, and finally obtain about 6 mg of the product, disperse the obtained product in 6 mL of ethanol, and store Reserve at 4°C.

[0028] 2) Preparation of hollow zinc sulfide nanomaterials

[0029] Get 1mL of the above-mentioned ethanol solution dispersed with solid zinc sulfide nanomaterials and add it to a 25mL round bottom flask, then dilute with 4mL of ethanol, the weight ratio of the solid zinc sulfide nanomaterials and ethanol is about 1:4000, Add 4 mL, ...

Embodiment 2

[0031] 1) Preparation of solid zinc sulfide nanomaterials

[0032]According to the existing literature (XiaoxiaoYu, JiaguoYu, BeiCheng, BaibiaoHuang, One-PotTemplate-FreeSynthesis of MonodisperseZincSulfideHollowSpheres and TheirPhotocatalyticProperties.Chemistry-AEuropeanJournal, 2009, 15, 6731-6739), 0.8mmol of zinc acetate and 20mmol of thiourea were added to 20mL of water Stir at room temperature for half an hour, then transfer to a reaction kettle, react at 140°C for 50 minutes, centrifuge and wash the reacted product, and finally obtain about 6 mg of the product, disperse the obtained product in 6 mL of ethanol, and store Reserve at 4°C.

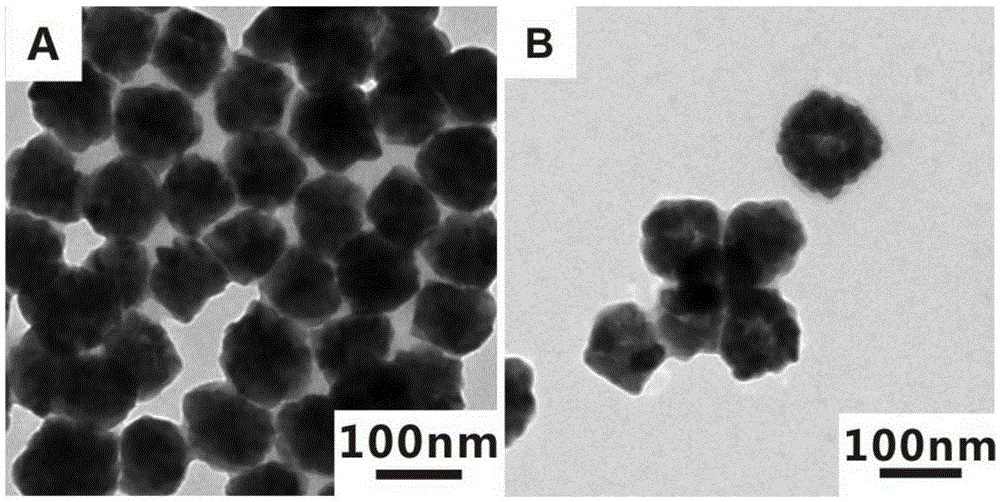

[0033] 2) Preparation of hollow zinc sulfide nanomaterials

[0034] Get 1mL of the above-mentioned ethanol solution dispersed with solid zinc sulfide nanomaterials and add it to a 25mL round bottom flask, then dilute with 4mL of ethanol, the weight ratio of the solid zinc sulfide nanomaterials and ethanol is about 1:4000, Add 4 mL, 4...

Embodiment 3

[0036] 1) Preparation of solid zinc sulfide nanomaterials

[0037] According to the existing literature (XiaoxiaoYu, JiaguoYu, BeiCheng, BaibiaoHuang, One-PotTemplate-FreeSynthesis of MonodisperseZincSulfideHollowSpheres and TheirPhotocatalyticProperties.Chemistry-AEuropeanJournal, 2009, 15, 6731-6739), 0.8mmol of zinc acetate and 20mmol of thiourea were added to 20mL of water Stir at room temperature for half an hour, then transfer to a reaction kettle, react at 140°C for 50 minutes, centrifuge and wash the reacted product, and finally obtain about 6 mg of the product, disperse the obtained product in 6 mL of ethanol, and store Reserve at 4°C.

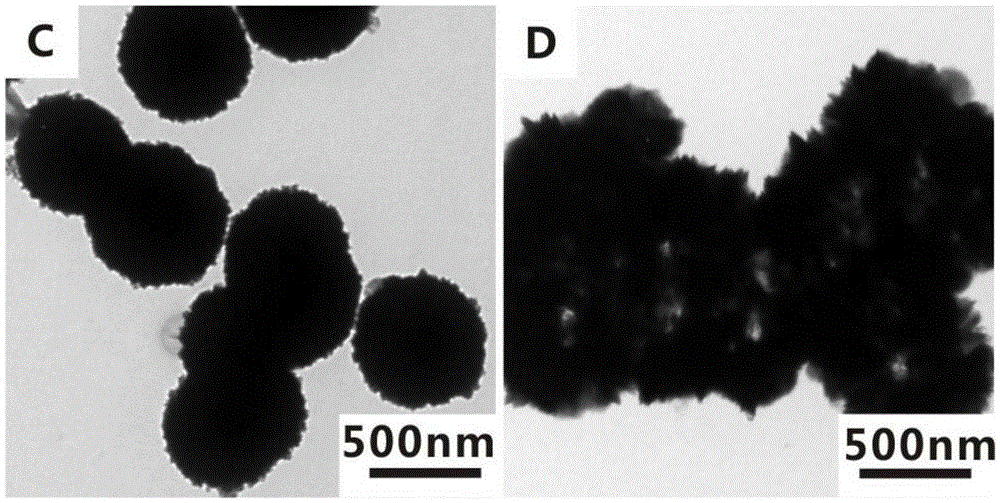

[0038] 2) Preparation of hollow zinc sulfide nanomaterials

[0039] Get 1mL of the above-mentioned ethanol solution dispersed with solid zinc sulfide nanomaterials and add it to a 25mL round bottom flask, then dilute with 4mL of ethanol, the weight ratio of the solid zinc sulfide nanomaterials and ethanol is about 1:4000, Add 4 mL, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap