Cyanate ester resin prepolymer with excellent space environment property, and prepreg, preparation method and application thereof

A cyanate resin, space environment technology, applied in coatings, adhesives, etc., can solve the problems of no prepreg and composite material space environment characteristics, and no solution to prepreg and composite material space environment characteristics, etc., to achieve excellent space environment. The effect of high performance, excellent performance and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

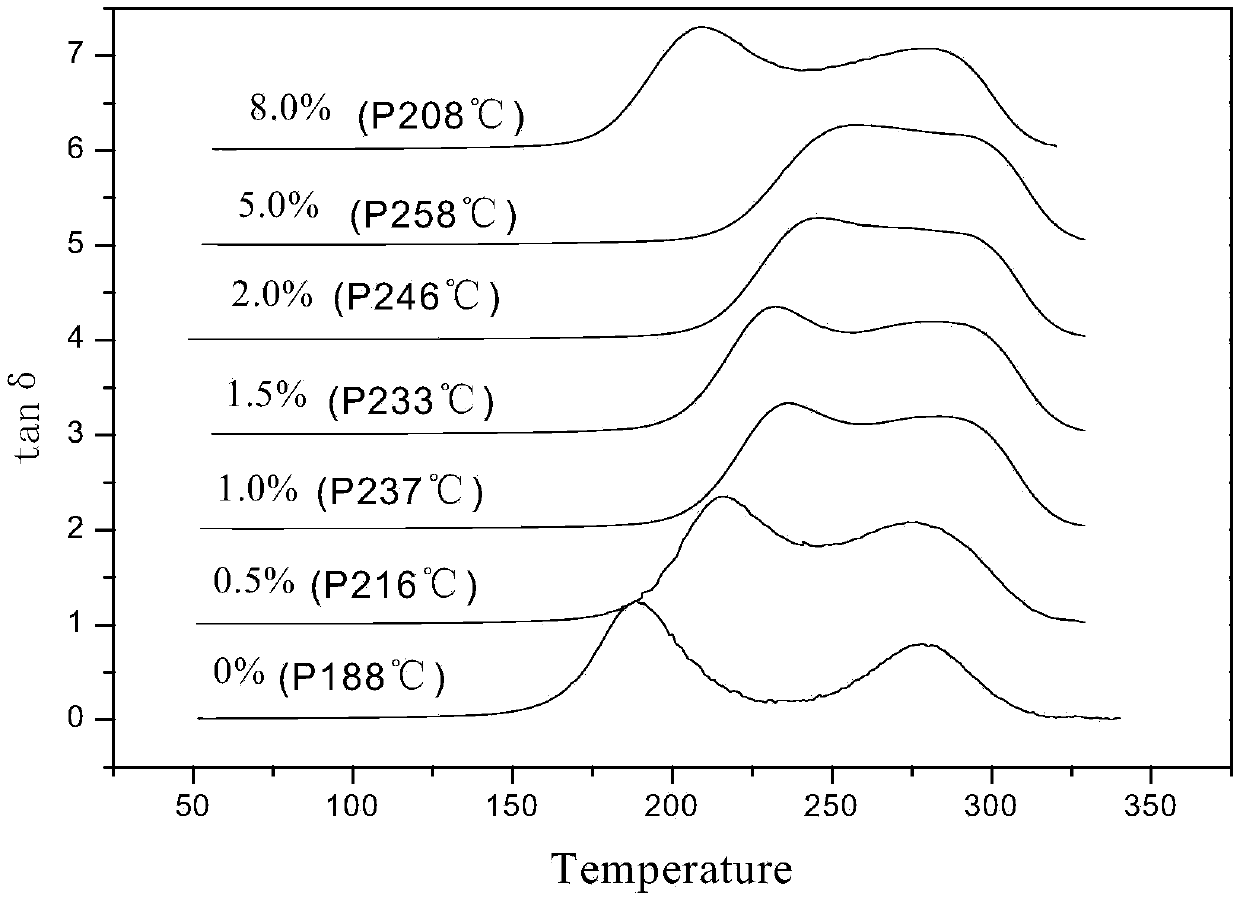

[0116] DMA test

[0117] RheometriScientificTM DMTAV dynamic mechanical analyzer is used, the test frequency is 3Hz, the heating rate is 10°C / min, and the test range is from room temperature to 300°C.

Embodiment 1

[0121] The bisphenol A type cyanate monomer and epoxy POSS, wherein the epoxy POSS is EOVS, its mass content is 0.5% ratio, and the bisphenol A type cyanate monomer mass content is 99.5%, carry out melt blending , the reaction temperature was 160° C., and the reaction time was 12 hours to obtain a cyanate / EOVS prepolymer. The obtained prepolymers were respectively cured and molded according to the curing process of 130°C / 1h→180°C / 2h→190°C / 1h. The Tg of the resulting product is bimodal, being 216°C and 276°C respectively, such as figure 1 shown.

Embodiment 2

[0123] Same as Example 1, except that the mass content of EOVS is 1.0%, and the mass content of bisphenol A type cyanate ester monomer is 99%. 237°C, 283°C. Such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com