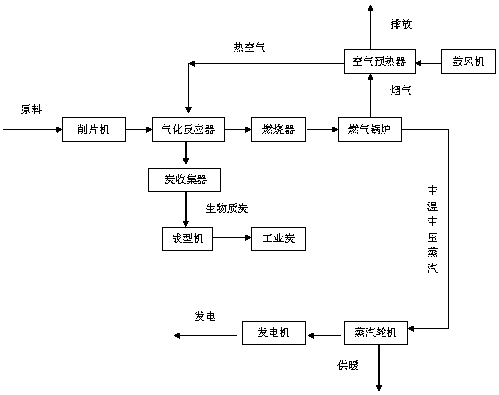

Technology of Mass Biomass Updraft Fixed Bed Gasification for Cogeneration of Electricity, Charcoal and Heat

A fixed-bed gasifier and fixed-bed technology, which are applied in the chemical industry, petroleum industry, and the manufacture of combustible gas, to achieve the effects of no secondary pollution, diverse products, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Embodiment Take Pinus sylvestris as an example

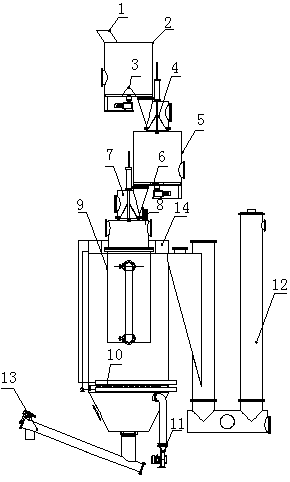

[0045] 3MW and above block biomass updraft fixed-bed gasification power generation co-generation process of electricity, charcoal and heat: the block is collected and pretreated, and the wood is sliced to about 6cm with a drum slicer, and the moisture content is controlled. Below 20% (if it is greater than 20%, it needs to be dried by drying equipment such as drums), it is sent to the hopper in front of the furnace by belt conveyor and elevator, and then sent to the gas-charcoal cogeneration up-suction fixed-bed gasifier, and the gas-fired boiler The waste heat of the tail gas produces hot air as a gasification agent, and the oxidation-reduction reaction occurs at a temperature of 600-800°C to generate hot gas (the calorific value of the hot gas is about 1200Kcal). After gasification, the temperature of the hot gas generated is about 300°C. The blower supplying the gasification agent in front of the gasifier blows into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com