Vacuum furnace for continuous production

A vacuum furnace and vacuum technology, used in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of affecting reaction temperature and pressure, long production cycle, troublesome operation, etc., to improve energy efficiency, low processing accuracy requirements, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

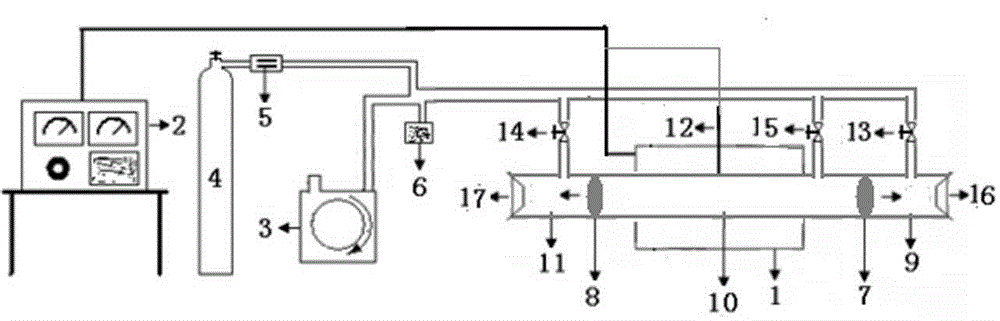

[0024] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0025] Such as figure 1 The vacuum furnace for continuous production shown is composed of a vacuum furnace body 1, a temperature controller 2, vacuum acquisition and detection instruments (3 and 6) and an air charging system. The material passage in the vacuum furnace body 1 includes a feed area 9, a product outlet Zone 11 and reaction zone 10, with good sealing and no magnetism, are generally quartz tubes, high-purity corundum tubes or non-magnetic stainless steel tubes; iron baffles 7 and 8 with sealing rings at both ends of the reaction zone 10 can act on the magnetic force of the magnet Open or close the channel, and have good sealing; thermocouple 12 is installed in the middle of the vacuum furnace body, and the bottom is close to the reactor, so as to accurately measure and control the reaction temperature.

[0026] The gas charging system is composed of a gas st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com